TARA-6 Yard Slugs/ TARA-6 Road Slugs

The Georgia Road embraced the use of slugs from its inception in the mid 1990s. Many of the units were inherited from the Central Alabama & Southern RR (CA&S) bankruptcy estate and worked to rebuild, reconfigure and add units to increase tractive effort in heavy yard, transfer and even road service. Modern microprocessor control systems on upgraded “mother” locomotives and on upgraded and remanufactured slugs made their use efficient in many applications across the combined system. The use of slugs was viewed as an enhancement of horsepower as opposed to substitution for typical multiple unit yard and road sets. This philosophy reduced the potential of power shortage caused by too much reliance on slug applications being used to fill in for powered locomotives. As a result, slug usage in both yard, transfer and road service gave power assignment a slight edge over minimum assignment requirements. This also extended the use of core units that otherwise would not be suitable or economically viable due to age and lack of integrated modern technology.

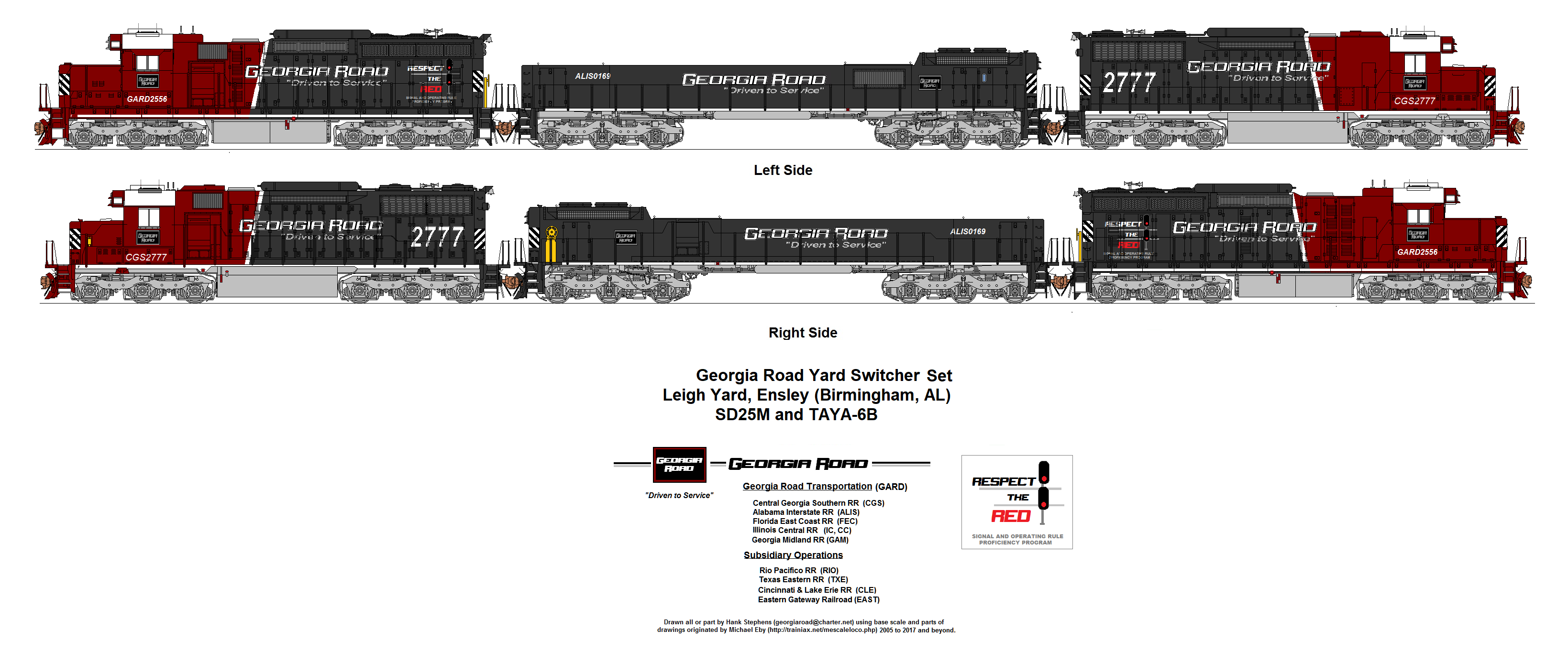

Georgia Road uses its own unique acronym when referencing its slugs. TAYA is short for “Tractive Assist-Yard Application” with the number following indicating the number of axles. TARA is short for “Tractive Assist-Road Application” with the number following indicating the number of axles. The addition of a “B” behind the axle number indicates the lack of an operable cab. This allows the power desk to assign these units based on general parameters in any applications, based on job specific needs and typical consist generation for trains.

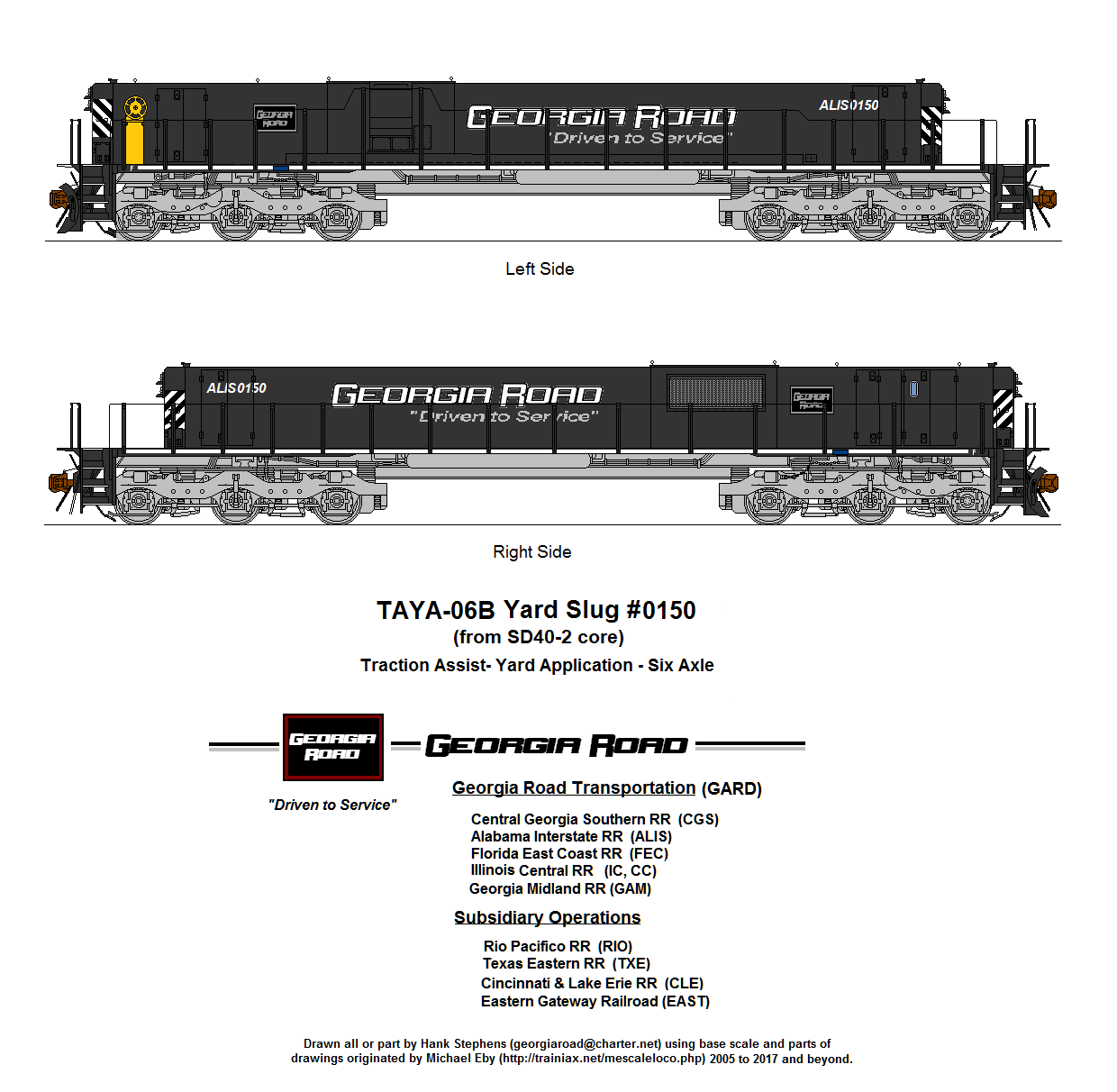

TARA-6 Yard Slugs

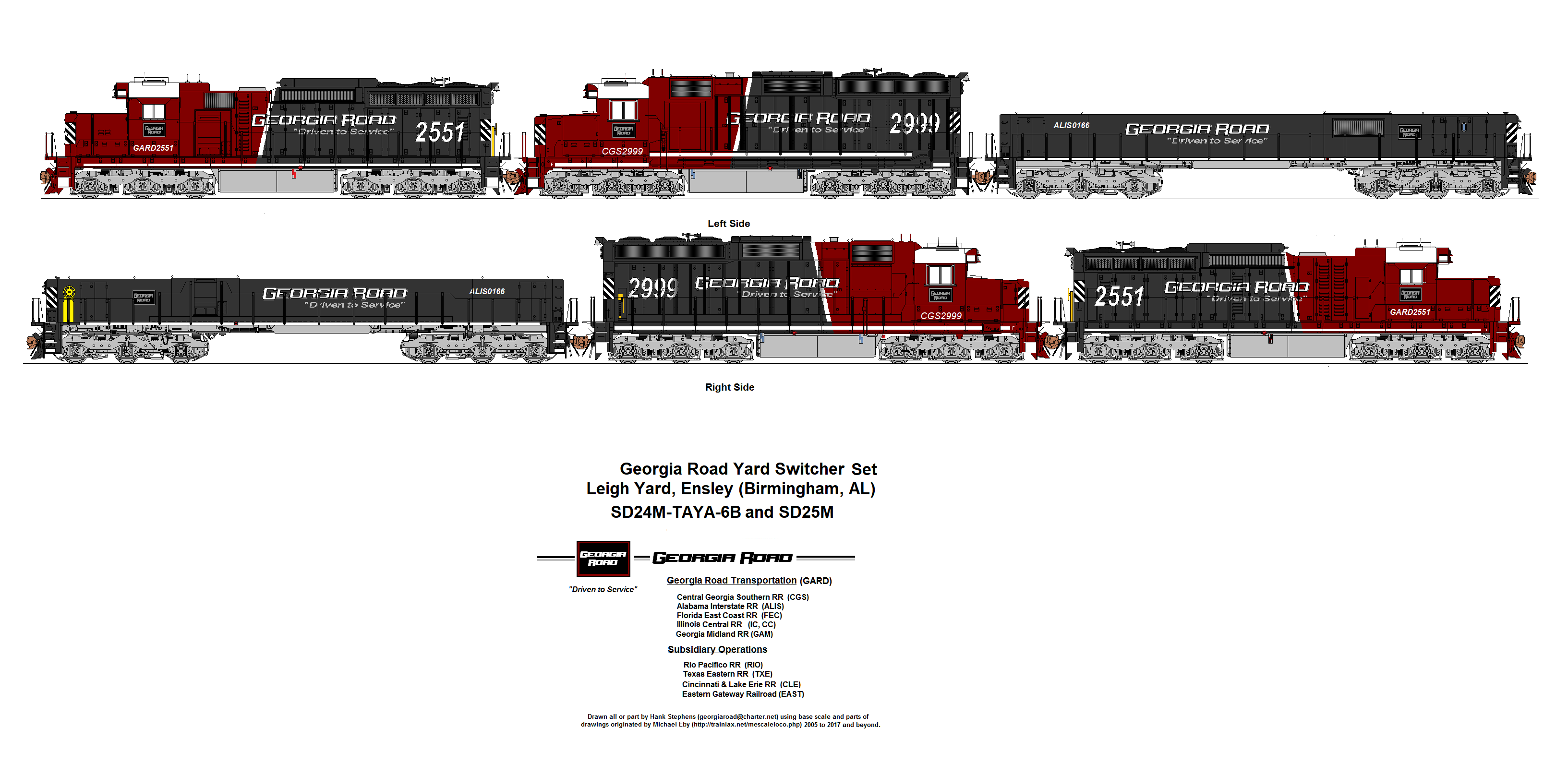

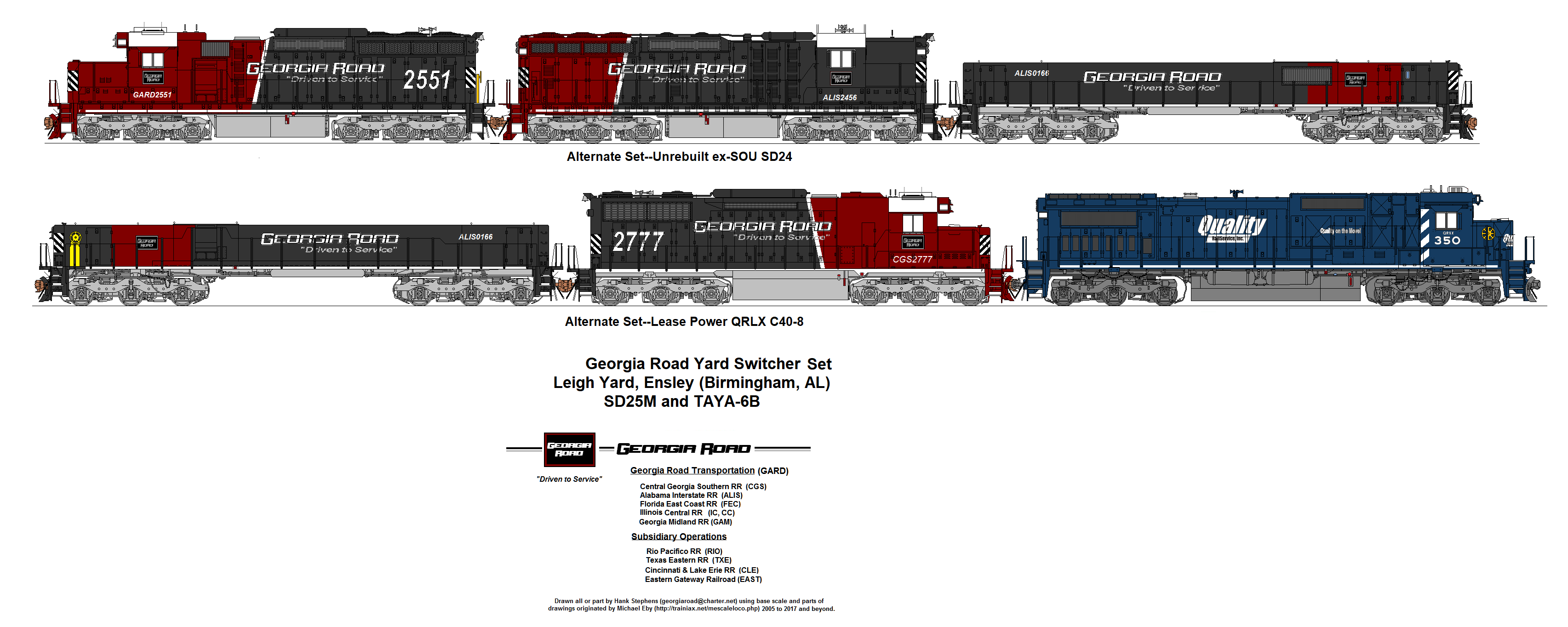

Georgia Road TARA-6 slugs are a small grouping, used primarily in terminal classification yard service. These work transfer, hump, trim and flat sorting tasks. Most are paired with lower horsepower 6 axle units, geared for and better suited for low-speed heavy switching. The bulk of these units work in hump and trim sets at one of the several major classification yards on the combined system. In recent years, six axle versions have slowly pushed four axle yard slugs from the roster, mainly due to the longer and heavier trains of the 21st century where block swapping is preferred over terminal classification. The extra axles allow for more tractive effort and facilitate the movement of longer and heavier cuts of cars typical of modern yard operations.

| Road Number | Model | Total Units | Notes |

| 0150-0158 | TAYA-6B | 10 | 1 |

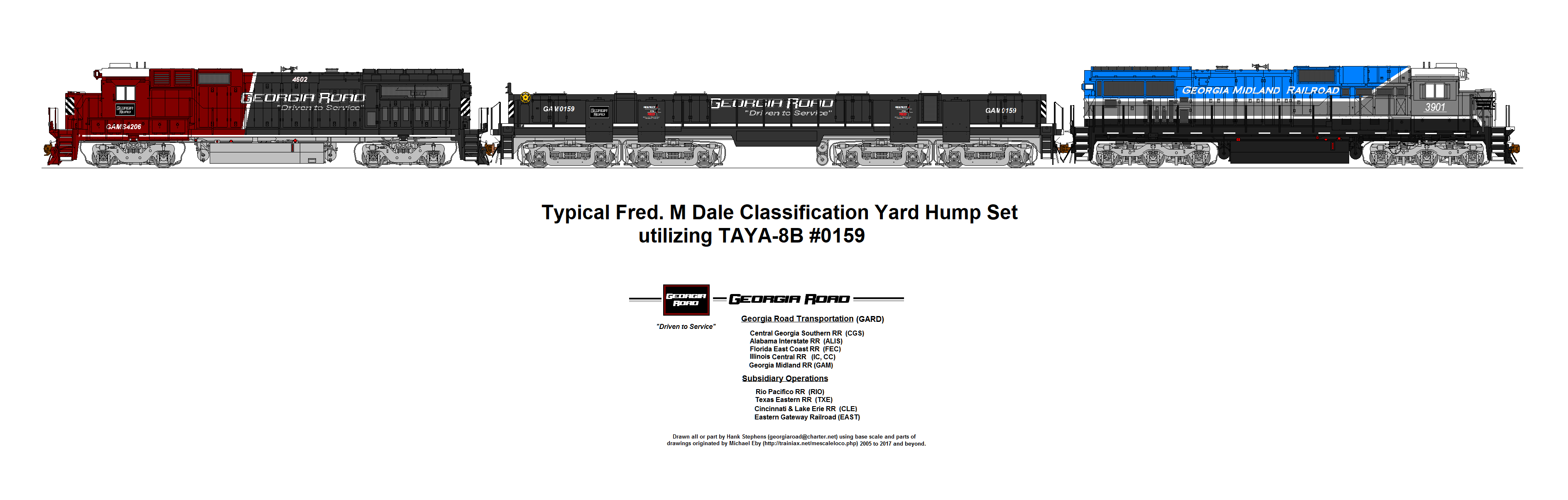

| 0159 | TAYA-8B | 1 | 2 |

| 0160-0163 | TAYA-6 | 4 | 4 |

| 0164-0169 | TAYA-6B | 6 | 3 |

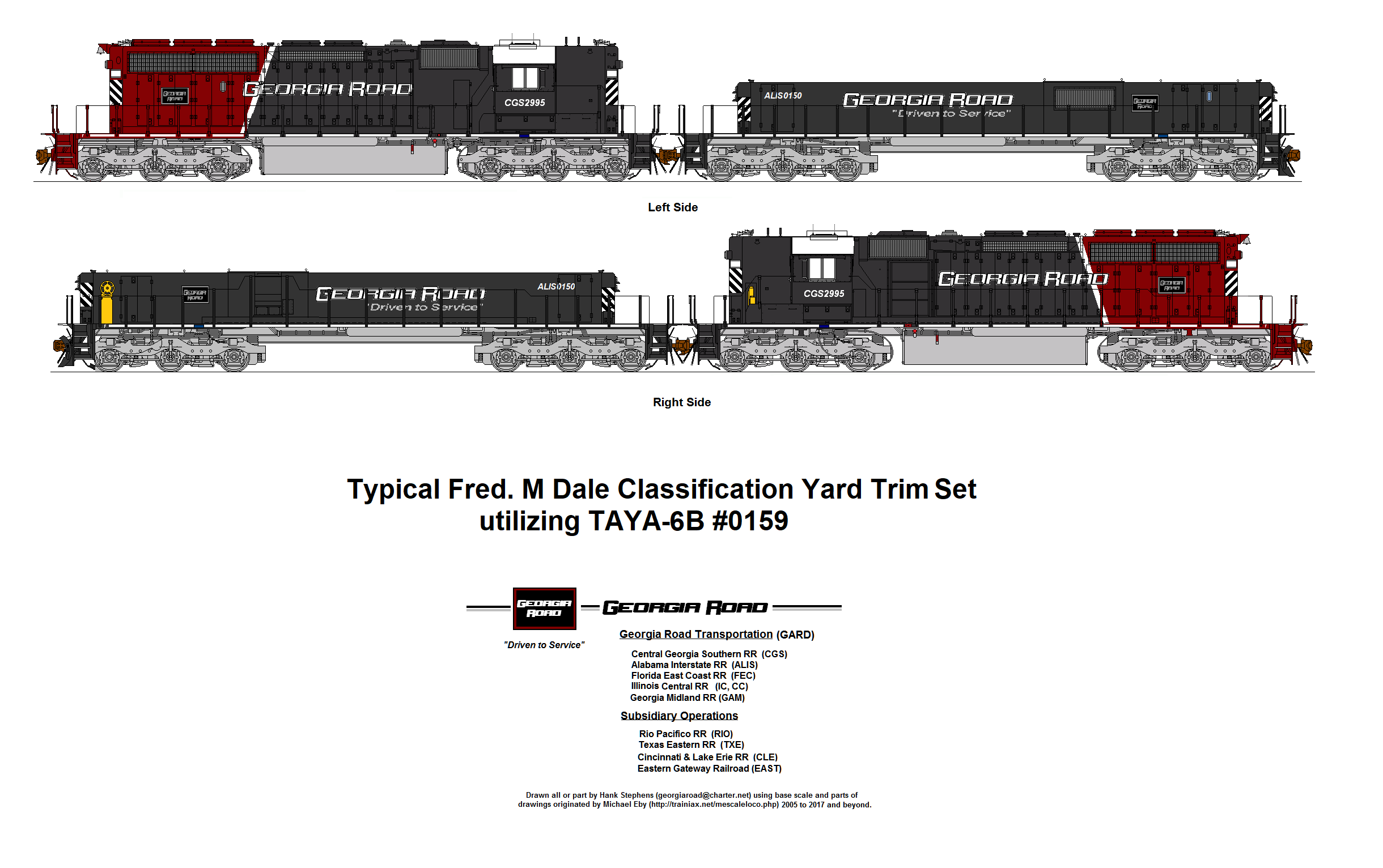

Note 2– unit 0159 rebuilt from U50 frame as a double ended yard slug by GAM. Each end takes power from the control locomotive attached there, creating a double pair of mother-yard slugs. Currently assigned to Fred M Dale Hump yard in Birmingham Terminal Subdivision.

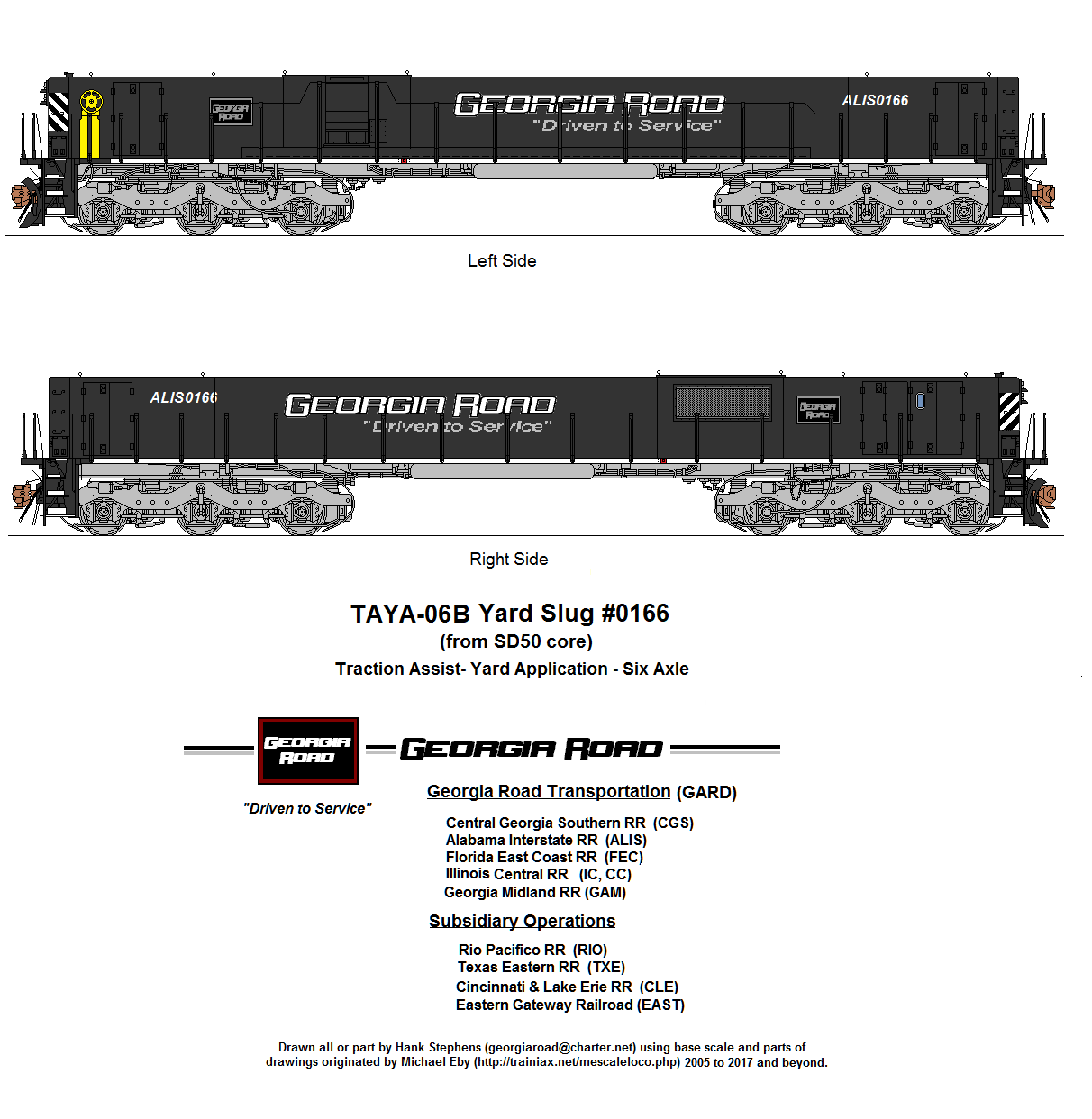

Note 3– units 0160-0165 rebuilt from SD50 frames. 0164-0165 units had dynamic brakes added and assigned to Macon hump.

Note 4– unit 160-163 rebuilt from SD7/9 frames and equipped with switcher type cabs and mated to SD38-2/ SD38-3 pairs. 0168 and 0169 had dynamic brakes added due to grades at Macon hump.

The core group of Georgia Road slugs came from a group of eight ex-Union Pacific Railroad (UP) slugs inherited by predecessor Central Alabama & Southern Railroad (CA&S). CA&S acquired these from various scrappers, rebuilding them and assigning them to the former NS Norris Yard classification yard in Macon, GA and various flat yards around its original ex-CofGA trackage. By the time of the Georgia Road assumption of the CA&S estate, most were out of service due to heavy maintenance needs typically deferred by the CA&S in its final days. Georgia Road restored these slugs to service, but soon found the mostly 4 axle fleet was sorely outmoded for the increasingly heavy railcars and trains they regularly worked in the yards. As a result, Georgia Road commissioned the completion of modern slug conversions of various six axle cores. The largest group was several SD40-2 cores configured into TAYA-06B slugs for use with ex Southern high hood SD40-2s used in heavy switching where the high short hood did not create a disadvantage and as a result did not need immediate shopping a chop nose and upgraded cab. These units replaced GP9B TAYA-4B slugs that were eventually completely rebuilt for road service as TARA-4B units mated to GP40M-3 rebuilds.

The SD40-2 TAY-06B units were deemed very successful and constituted the largest model of Georgia Road slugs. They could be used in heavy classification, trim, transfer and even flat yard classification using R/C platforms with no setup time, provided a mother unit was handy. All units are currently active, with the group split between Macon, Birmingham and Memphis terminals on the combined Georgia Road system.

Georgia Road was so satisfied with the SD40-2 TAY-06B units that it requested additional units for assignment at various flat switching yards. With no more SD40-2 cores due to the TARA-6B SD40-2 slugs built for the IC lines, Stephens Railcar Services moved to its backlot of SD50 cores held back for the TGX Program rebuilds. Six additional TAYA-6B slugs were produced using ex UP -CNW SD50 cores that were rejected by the TGX Program. Two of the six, 0168 and 0169, had dynamic brake assemblies added using surplus assemblies removed from the ICG TARA-6B builds. The dynamic equipped units worked well in the flat “block swapping” yards where large cuts of cars had to be pulled and added to trains not terminating who still interchanged traffic to and from the yard. These SD50 core slugs would be added to pairs of SD25M rebuilds of first generation power. The COVID-19 Pandemic reduced the need for additional units, which Stephens Railcar sold to Georgia Road controlled GATEWAY System roads.

Georgia Road inherited a notable “one-of-a-kind” yard slug through its acquisition of the Georgia Midland Railroad System (GAM). Slug #0159 was originally built by the independent GAM for use in heavy grain switching on its Gainesville Midland branch that ran from Gainesville, GA south to Madison where it joined the GAM former Georgia Railroad mainline linking Atlanta and Augusta, GA. the Gainesville Midland was home to several large soybean processors, chicken feed mills and soybean loaders. The 4O miles between Gainesville and Athens regularly sourced 3-5 soybean train per week along with regular moves for several Seaboard Farms feed mills and the large Cargill Soybean processor on the line. Road trains had to regularly shift long, heavy cuts of grain cars in and out of long leads, making slug use opportune. GAM was known as a stalwart GE holdout when it came to is locomotive roster. It maintained everything from first generation U25B and U25Cs to brand new C44-9W units. It an odd twist of fate, GAM found the remains of a U50 in a midwestern scrapyard which the owner contemplated restoring. After extracting the hulk and shipping it to their Cedartown, GA back shop, GAM found it to be too heavily stripped. With the need for road slugs around Gainesville, a plan was hatched to rebuild the frame into a “double slug”. The paired trucks on each side were isolated independently and set up to draw power from a control locomotive mother unit on that side. This produced two single ended slugs joined by the frame, but independent of each other. Numbered 9999, the slug went to work in Gainesville with a variety of six axle locomotives configured as control mothers. After the Georgia Road acquired the GAM in the early 2000s, new AC4400W locomotive purchases and decentralized grain operations made the roster oddball slug use less desirable. It was eventually stored at the former Cedartown shops with an unknown future. Fast forward only a few years later and GARD would purchase the former NS hump yard in Irondale, as NS deemed it surplus. Georgia Road relocated its classification that was spread out between small yards at Atlanta (Howell) and Birmingham (32nd St) to the reconfigured NS yard, now called the Fred M. Dale yard. Georgia Road resumed hump operations and pulled the GAM eight motor slug for use as part of the primary hump set which used former GAM 9-44C and B40-8 units. The prevalence of GE units at the yard was no accident, as the former GAM Cedartown backshop was closed in favor of the larger and more modern ex NS steam shop at Irondale. The slug was given the TAYA-08B designation and renumbered to GAM0159. The longevity of the 0159 can be attributed to its B+B -B+B configuration which reduces wear on the yard trackage as it can flex similar to a traditional four axle slug. The unit is active and regularly works hump and transfer service in the Birmingham Terminal Subdivision.

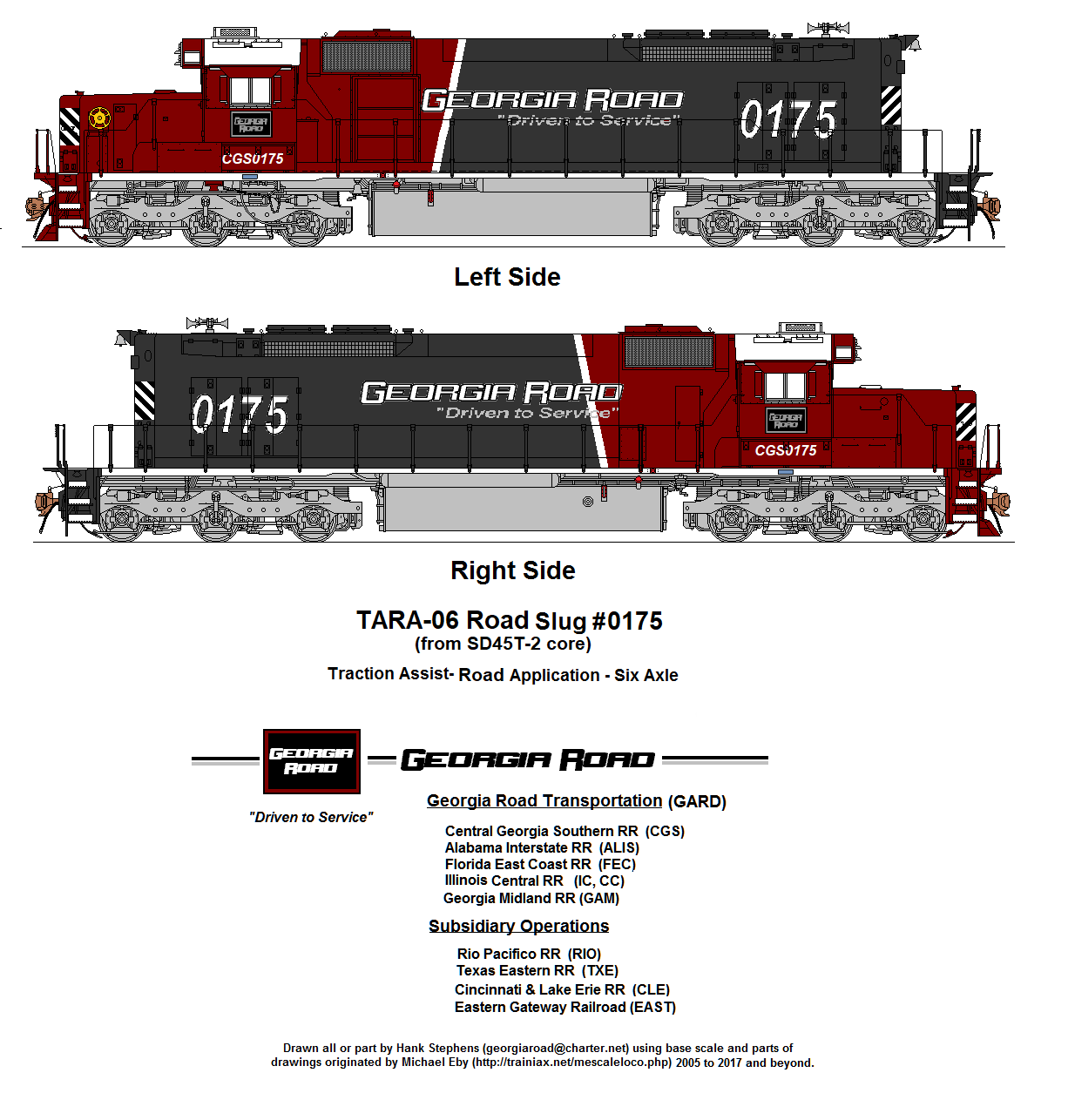

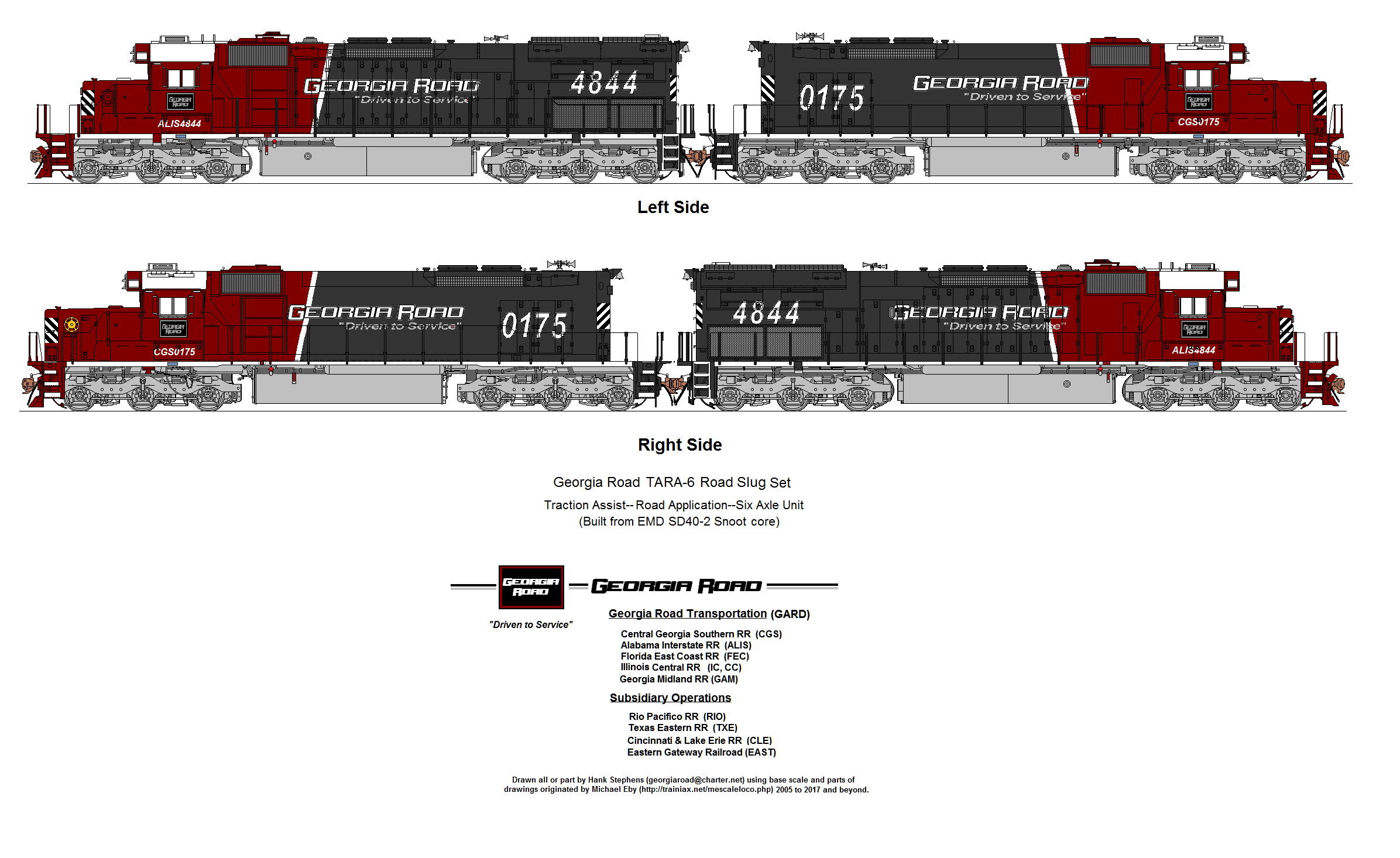

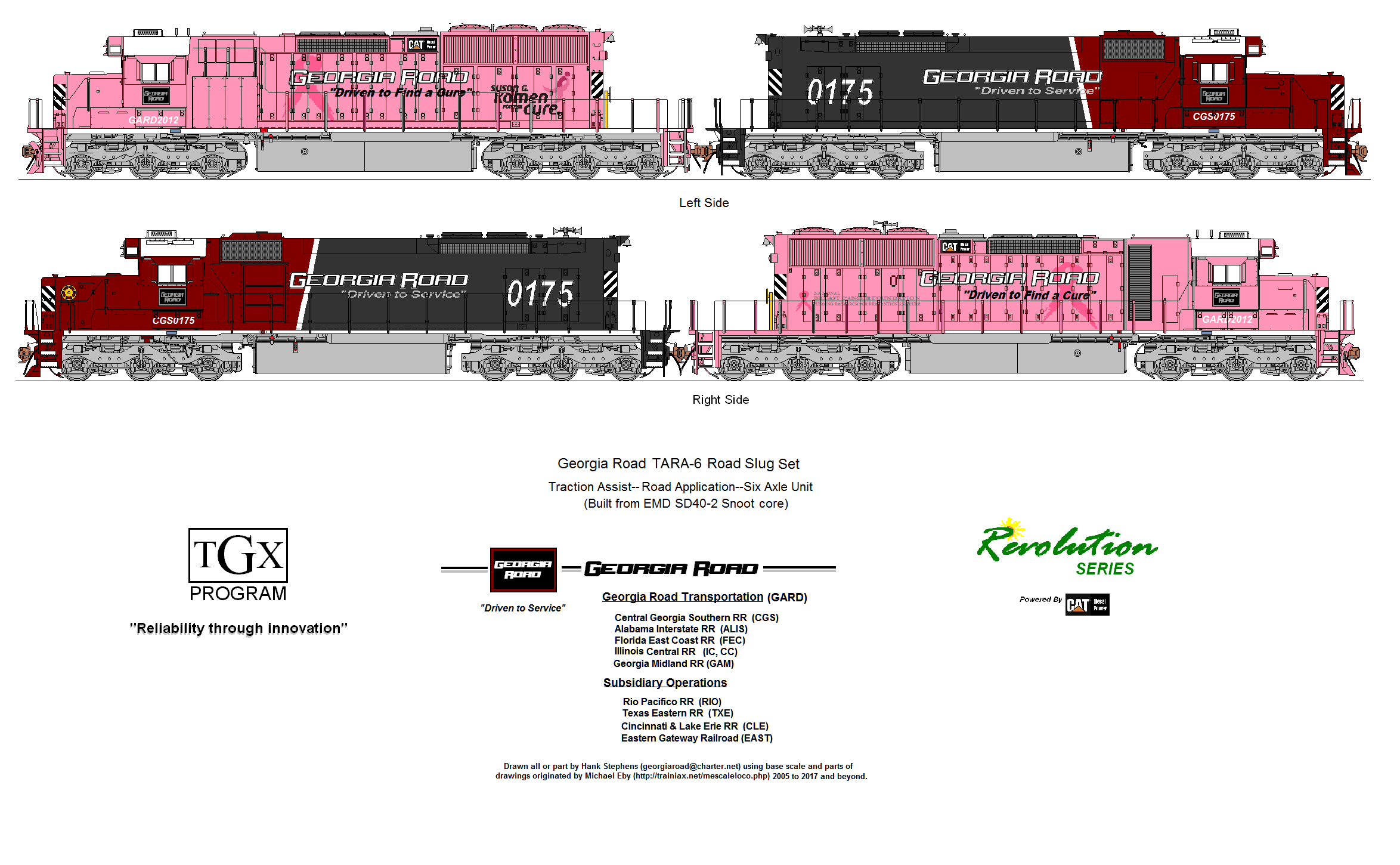

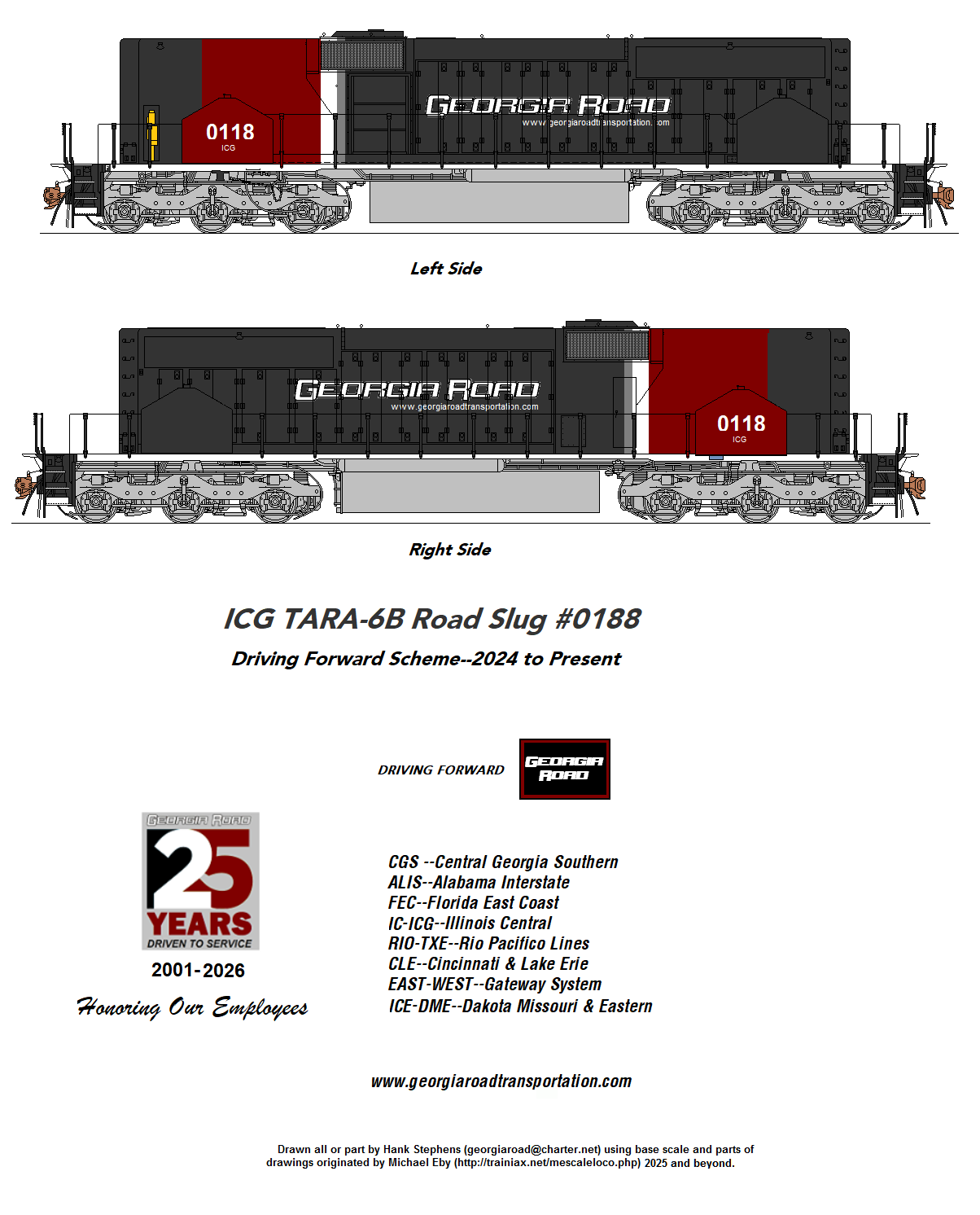

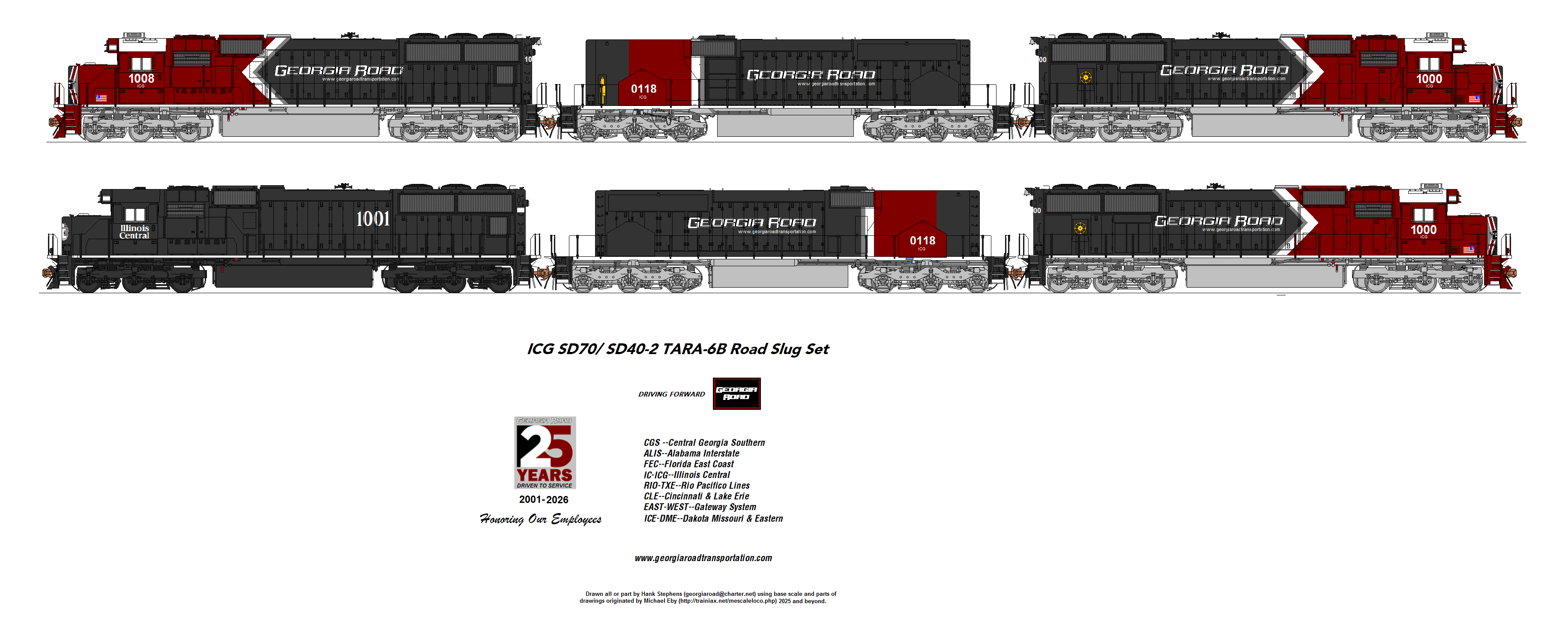

TARA-6 Road Slugs

Georgia Road

| Road Number | Model | Total Units | Notes |

| 0170-0185 | TARA-6 | 16 | 3 |

| 0186-0199 | TARA-6B | 14 | 4 |

Note 4–Units built from former NS SD40 and SD40-2 high short hood units. Dynamics removed and mated to pairs of IC SD70 units and assigned to general and manifest service.

Georgia Road pulled worn out former Southern SD40 and SD40-2 units for double ended slug conversion and mating with pairs of IC SD70s. The first order of IC SD70s were being given a mid-life overhaul at the time and units were selectively getting the new “Driving Forward” colors as they needed painting. These sets were set to work shuttle grain trains and heavy moves in the flatter Midwestern part of the IC lines. Georgia Road resurrected the ICG reporting marks for rebuilds assigned to the IC lines, while others assigned to system wide service will receive GARD system marks.

Georgia Road started experimenting with six axle road slugs in the early 2000s. After seeing wide range success with four axle road slug pairs, the next logical step was to attempt a similar program with six axle road slug pairs. After creating six pairs for evaluation in system wide service, the six axle slug program was increased to a total of 16 units. These were created from various, SD40, SD45, SD40-2 and SD45T-2 cores. These units were set up with full cabs and could refuel the mother as this design kept its fuel tank. The dynamic braking was shifted to the rear to reduce noise in the locomotive cab, and to allow a larger block of concrete to be poured where the engine block originally stood. These units were mated with SD40-2, SD40T-2 and SD60 units. They are on the active roster and work in system wide assignments.