GP25M /GP25MB

GP25M

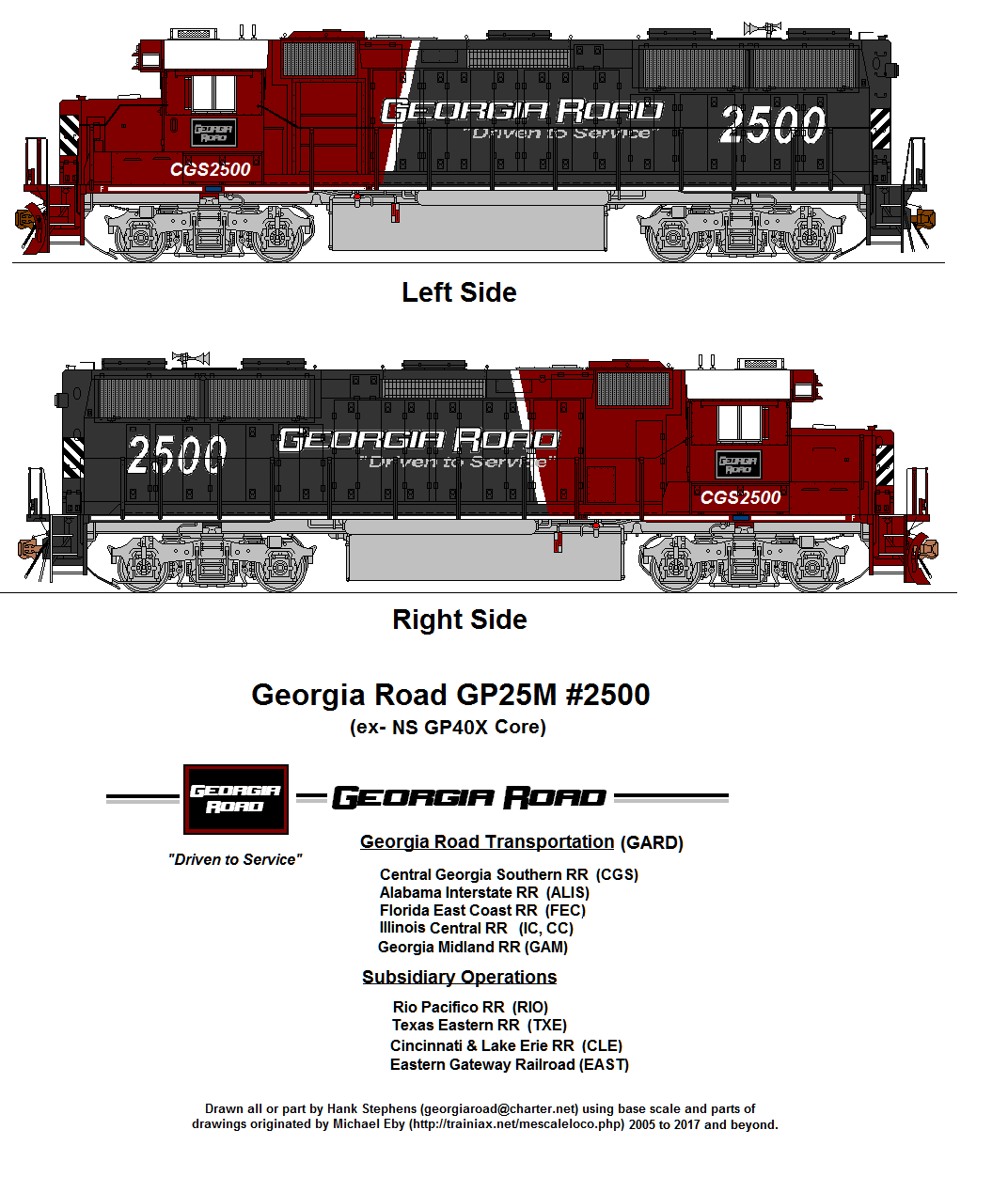

The 25M program was commissioned by Georgia Road in the early 2000s to create a Class of locomotives to run with GP40-3 (GP40-2 and GP50 rebuilds), B40-8E, GP60 and GP60B units assigned to the various QuickSilver Intermodal trains and the lucrative Eagle Flyer APC Land-Bridge Contract. Georgia Road was heavily invested in four axle power at the time, and the addition of the IC created a need for replacements for its aging GP40R fleet used primarily to move its intermodal trains. prior to the Georgia Road acquisition. Builder new options were disappearing, as EMD and GE focused on their respective six axle offerings of the time. No new four axle offerings were presented by either builder. While Georgia Road was beginning the transition to six axle power on its crack APL Contract trains, the need to replace the GP40R fleet and support the new QuickSilver Intermodal branded Optima Service bolstered a need for need for additional four axle power.

With no builder new options, Georgia Road set out to rebuild the oldest of its GP40-2 units into GP40-3 configuration, even going so far as pulling the less than stellar performing GP50s into the program. While successful, the GP40-2 core numbers available for rebuild were small in comparison to older GP40 and GP40R groups. Along with the GP40Rs, Georgia Road inherited many ex-SOU GP30, GP35, GP38 units with high hoods. Adding to this was a long list of IC GP-11 Paducah rebuilds, GP28, GP38, GP38AC, GP38-2 units which were not suitable for the high availability needs of the Georgia Road intermodal business. Georgia Road needed to reconfigure its roster by renewing, replacing and adding new power in an effort to bolster the aging IC roster. New power came in the form of nearly two dozen kit built GP60i units from a canceled Conrail order assembled at Stephens Railcar. These were intended to follow up and augment former CA&S GP60M and GP60B units Georgia Road inherited from its bankrupt predecessor. The kit built GP60i units quickly began to resemble the soon to be released TGX program GP65M with similar hi-ad trucks and specifications. As the last of the units were assembled Georgia Road extended its purchase of rebuilder new Stephens Railcar TGX Program GP65M and GP65MB units when GMLD refused to allocate production space or additional GP60i kits. This influx of new and rebuilt power could not keep up with the growing needs of the former IC lines, where Paducah rebuilds were reaching their economic life expectancy and were being retired in blocks. The Georgia Road 25M Program came to pass to further address Georgia Road’s appetite for four axle power to work high availability assignments. It tapped Stephens Railcar to create the specification and build units from the scores of IC GP40, GP40R GP38 and GP38AC units now holding down road and local service as they dropped from priority intermodals to road switching. The idea was to create a unit equally home on fast intermodal trains running with fast four axle power.

Stephens Railcar is notable in its TGX Program of third and fourth generation rebuilds designed to meet increasingly stringent EPA emissions requirements. After several months of study and evaluation of Georgia Road roster needs, Stephens Railcar presented the railroad with the 25M Rebuild Program in early 2002 The specification called for a turbocharged medium horsepower road switcher that would be equally adept at moving fast intermodal trains or working road switching assignments over the combined Georgia Road system. These rebuilder new medium horsepower units would utilize a GP30, GP35, GP38 and, GP40R core units pulled from Georgia Road ranks. To prevent a severe shortage of power as Stephens Railcar pulled from the active roster, it would also rebuild from its own stocks of GP40 and GP50 cores originally acquired for the TGX Program. The specifications for the new design would be built around an OEM EMD 12cylinder turbocharged 645 primemover, have a modern clean cab with minimum 26L braking, new D77 traction motors on fully remanufactured trucks, new electrical cabinets, wiring and third generation microprocessor control system. Former Southern GP30, GP35 and GP35 units would be configured as booster units with hostler controls, allowing utilization of the high short hood and reduce costs. The initial order was for 30 cab equipped GP25M units with an additional GP25B units.

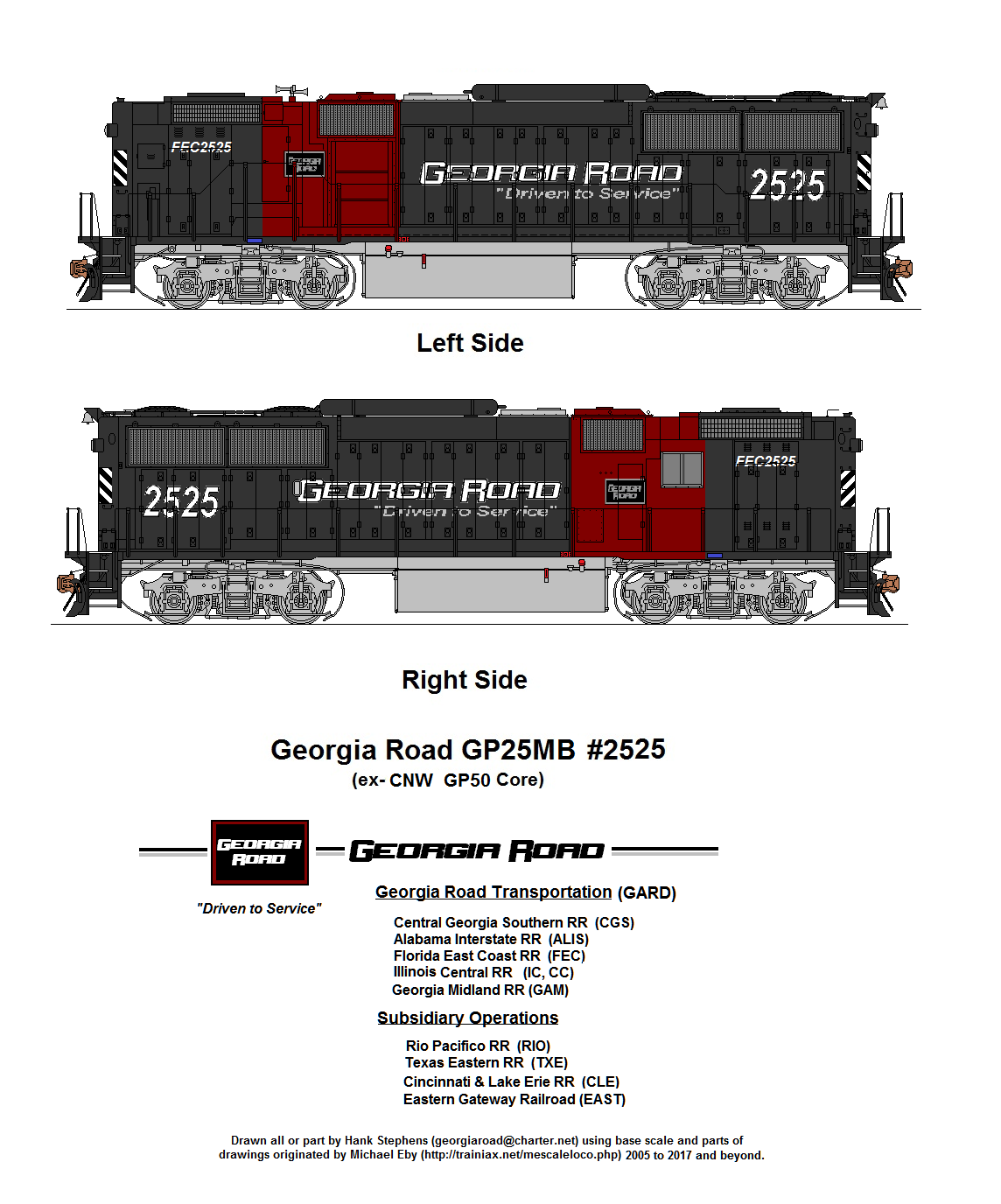

GP25M units built from GP40X and GP50 cores rolled off the production line at Stephens Railcar in 2004. The design was quickly dubbed a success in terms of operation and cost, resulting in Georgia road to place an additional order through 2006. The total fleet in 2018 at program end stood at 125 GP25M units and 50 GP25MB units when Georgia Road ordered the first of the SD25M six axle variants, making the 25M Program the longest running rebuild program in Georgia Road and Stephens Railcar history.

Four axle power design reached its pinnacle at 4000hp on a four-axle configuration and were falling out of favor as power for priority intermodal and manifest pools. Railroads were buying six axle power to move these heavier and longer to eliminate wheel-slip occurrence experienced by high horsepower four-axle units.With the exception losses due to wreck damaged units, the GP25M and GP25MB fleet remains intact and working in assignments as designed. The standardization of six axle power on most manifest and intermodal power threatened to push the units down the roster by the late 2020. The saving grace proved to be the growing QuickSilver Intermodal Optima Service, which employed fast short sprinter trains between “hub and Spoke” terminals and intermediate points. The GP25M and GP25MB sets proved opportune in these pools as they dropped completely off the Eagle Flyer APC Contract trains and long-distance intermodals. The result was the GP25M and GP25MB fleet continued to hold down these regional intermodal moves, with only a very few falling down to road switching pools. As of 2023, the 25M program continues, mainly producing six axle SD25M variants, but still kicking out GP units to replace wrecks or major failures.

GP25MB

The GP25MB was a variant of the 25M program specifically created to take advantage of the high short hood equipped ex SOU GP30, GP35 and GP38 locomotives inherited by Georgia Road when it started operating in 1996. Georgia Road also had a small fleet of builder new GP60 and GP60B units built for predecessor CA&S in 1992 and 1993 so the use mixed cab and cab-less units was nothing new. The original intent of the 25M Program was to bolster numbers in the intermodal pools in which the GP60 and GP60Bs worked, but to provide a second life as these pools ceded to new, better suited six axle designs.

As with the GP60B, balancing the bridge load between the front and rear trucks was tricky. Unbalanced weight would create truck “hunting” or increase wear on wheels and bearings. Additional weight helped, but there was only so much that could be added before the design would begin to overload the track structure. With no cab, the front proved lighter, so fuel tanks were moved forward to even out the difference. Air reservoirs were moved to the high short hood to allow a “wrap around” tank to match fuel capacity of cab equipped units. The result of all these requirements created a configuration that is likely not to be confused with the GP60B or any other booster rebuild.

Another spotting feature is the addition of a hostler cab window on the right side of the locomotive. Georgia Road specified hostler compartments on its GP60B, which were shopped and modified in 2003 during a midlife overhaul. The modification was well received by shop personnel and road crews alike and became a standard requirement on any cab-less booster rebuilds to this day.