SD25M (Rebuilt SD24 and SD9 Cores)

SD25M

A hallmark of Class One railroads in their locomotive fleet management is efforts to rebuild and renew older generation power as a way to balance cost and reduce the need for more expensive new OEM power. Examples include ICG and its long running Paducah Rebuild Program, the UP 40N Program which ran hordes of SD and GPs into its North Little Rock Shops for modern upgrades, and ATSF which converted a fleet of old first generation F-units and early GPs for road switching through its concurrent Cleburne and Topeka Rebuild Programs. In many cases, it made more economic sense to buy new locomotives for the priority road trains, and delegate older power to yard and road switching duty. The older power saved money, but usually burdened their locomotive pools with diverse obsolescence. In order to reduce maintenance and standardize to aid in efficiency, many times a specific program was created to upgrade and standardize. Georgia Road was no different, though late to the scene due to its recent mid-1990s startup. However, it quickly moved to address its own older generation power issues in a series of rebuild programs.

Buying new locomotives was always the best option to modernize the road fleet, but also the most expensive. The intermodal and manifest pools were beefed up with new SD70M, SD70ACe and GE ES44AC units. The displaced older power filled physical needs of the less glamourous yard and switching pools. The yard and terminal pools had the upside of keeping the units closer to maintenance shops and failures did not bottleneck operations in the terminals with the ferocity of mainline operation. Reducing the demand on the units helped with reliability, though the daily grind in the yards and terminals was intended to squeeze out any economic value before retirement or rebuilding. Georgia Road saw value in updating and standardizing yard and switching pools in terms of flexibility and efficiency.

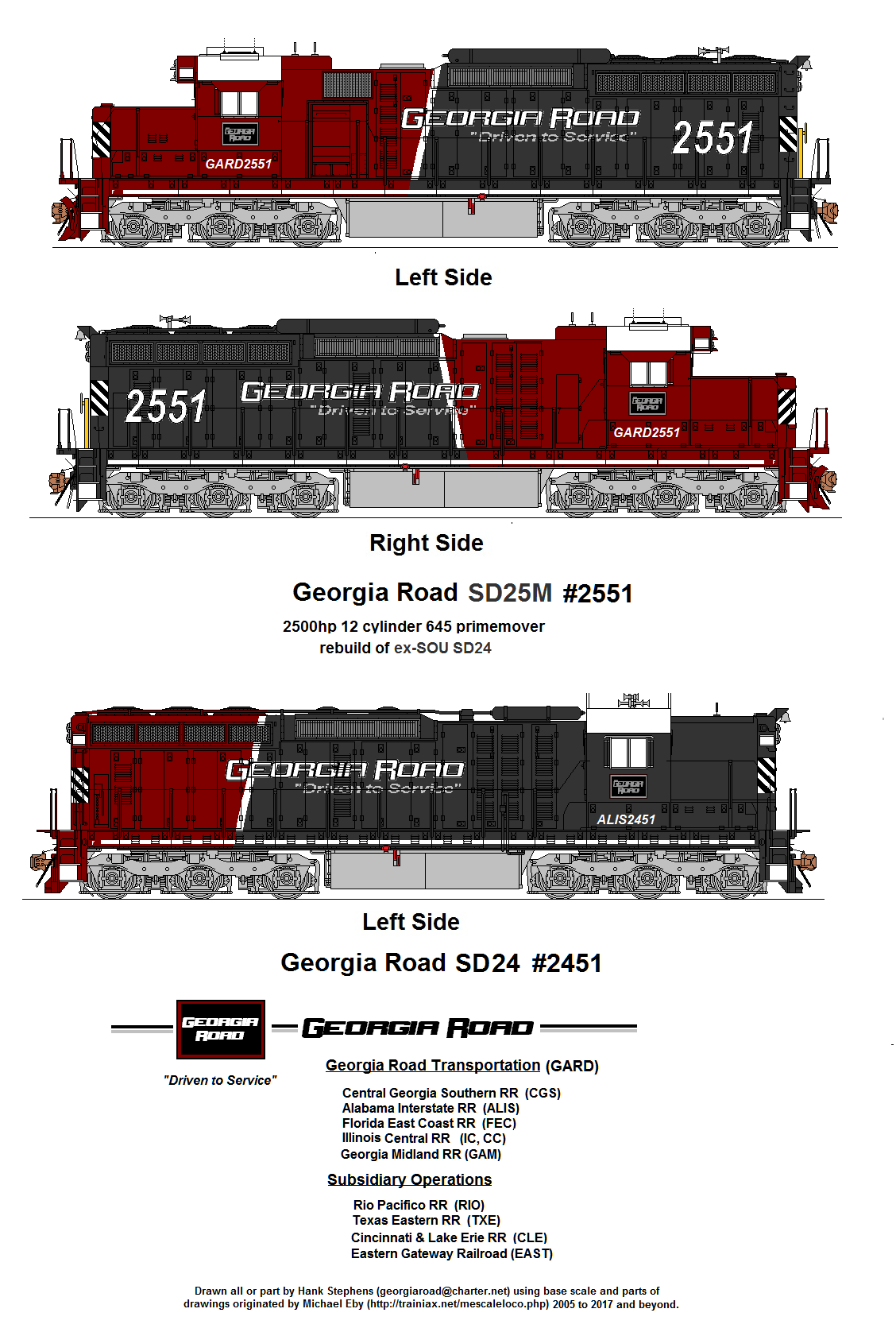

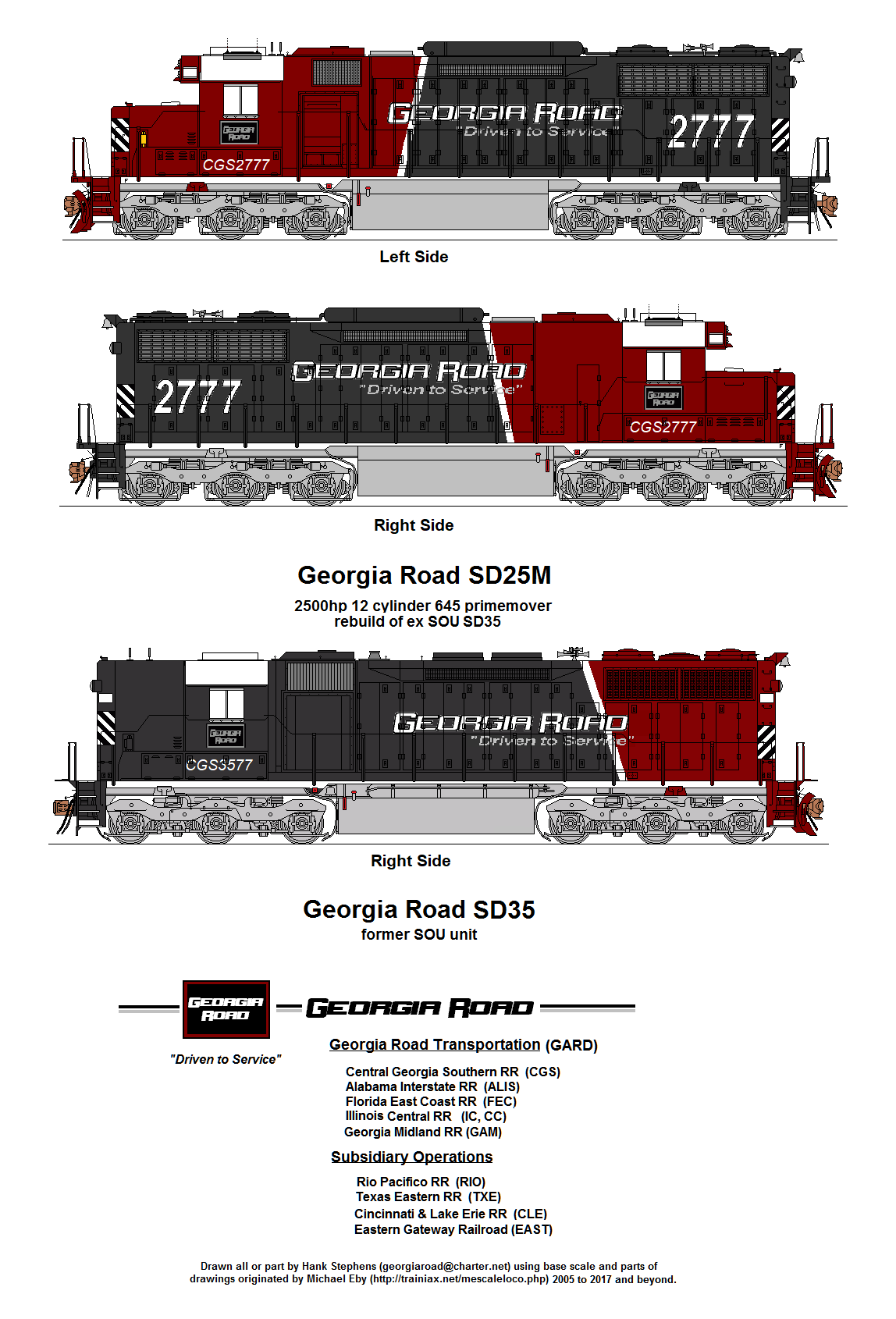

The 25M program was commissioned by Georgia Road in the early 2000s to create a group of general yard, transfer and road switching power from its large roster of ex SOU SD24 and SD35 locomotives. Georgia Road was the recreation of the bankrupt Central, Alabama & Southern Railroad (CA&S) of the 1980s. CA&S was a spin-off of the newly organized NW-SOU merger into Norfolk Southern similar to a Deep South version of the Wheeling & Lake Erie spin-off. The CA&S contained much of the old CofGA trackage, much of which was downgraded in the late 1970s and 1980s after Southern swallowed its competitor Central of Georgia. CA&S would add ex GM&O lines to the west and cast-off branches in South Carolina to create its system. CA&S came into being during the rise of intermodal and managed to capitalize on that fact and build a profitable business. The backbone of its fleet was dozens of SD9, SD24, SD35, SD40 and SD45 units, many pulled from the deadlines of the new NS as it modernized its fleet with late second and third generation power.

After the CA&S bankruptcy, Georgia Road inherited what was an eclectic and tired roster of late first, and early second generation power. Georgia Road immediately set about adding a mix of new and rebuilt power to modernize and restore reliability to the roster it inherited. SD40 and SD45s were remanufactured by the likes of VMV and MPI. Stephens Railcar was tasked with creating a program that would standardize the SD9, SD24 and SD35 units. With road power needs being filled with new and rebuilt second generation power, the less visible yard and switching duties struggled with very old and tired first generation SD units. The 25M Program was designed to produce a relatively standard configuration from the SD9, SD24. When these cores were depleted, Stephens Railcar pulled from SD35 ranks to extend the program and continue it.

The 25M Program gained its name from the “SD25M” model name designation of the program graduates. It began in the late 1990s aimed mainly at four axle power. At the time, Georgia Road was looking to bolster its fleet assigned to the fast intermodals, particularly the Eagle Flyer APL land-bridge service and its own QuickSilver Intermodal Service. The four-axle program concentrated on old GP35, GP38 and GP40R units built to run with newer GP40-2, GP60 and GP60B units in these high horsepower, medium weight sprint trains. The results were so successful that Georgia Road requested a similar specification to address its older six axle power. As a result, the original GP25M/GP25MB rebuild specifications were extended to SD25M rebuilds.

The SD25M specification was a complete rebuild of the core unit, covering a complete new modern Dash-2 cab, electrical system and 26L brake system. Powerplants were replaced with large bore, 12-cylinder turbocharged EMD 645-series engines. Free flow traction motor blowers fed completely rebuilt trucks with D77 traction motors. Hood louvers were simply plated over from the inside, and not removed. The general carbody of the core SD24 and SD9s remained intact, but one of the odd and most noted changes was the location of air tanks to the roof of the long hood. With most first-generation units lacking fuel capacity of later models, Georgia Road wanted its 25M rebuilds to operate as seamlessly as possible with second generation road units. This would require increased fuel tanks, and with limited space between the trucks, Stephens Railcar found it could reach capacity requirements by wrapping the tank completely around the frame. This displaced the potential of adding horizontal frame mounted tanks. With SD25 units already set up in this configuration, Stephens Railcar simply updated the system on its roof location. SD35 cares had their tanks moved to the roof, allowing the larger fuel tanks used by the SD24 cores to be used, thereby simplifying parts and fueling requirements in the field.