SD70ACe/SD70AH/ SD70AH-B

The 7700-7989 series was purchased new from EMD in 2005 as part of a 75-unit order from EMD earmarked for unit coal, grain and bulk commodities. The first 25 units were tacked on to a BNSF order and specifications were identical the BNSF units. Less than a year later Georgia Road completed purchase of the DME-ICE lines with the idea of completing its own access to the Powder River Coal Basin. At that point, the next fifty units were built behind the CSXT SD70AH order which used thicker steel to increase the weight and tractive effort to move heavy coal trains over its system. CSX was less than satisfied with its units and cancelled additional orders. Georgia Road picked up the vacated production slots and purchased the SD70AH version to beef up both Georgia Power and Alabama Power coal trains that now ran the whole distance into the Powder River Coal Basin via the new DME connection. EMD worked to correct issues of the early SD70AH’s nicknamed “thunder cabs” by CSX crews who complained of excess vibration and noise while using them as leaders. The Georgia Road units incorporated a traction system that could isolate individual traction motors, a feature on GE locomotives since the 1990s, but not used by EMD. A bad traction motor would require the whole truck to be cut out instead of the one offending motor. This effectively halved the traction of the EMD unit, a problem that could easily stall a heavy coal train with traction motor issues. CSX had a stanchly modern and predominately GE roster, relied on the advantages of individual isolation versus full truck isolation when traction motors failed. The combination of rough riding, loud cabs and losing half traction at the failure of a single traction motor soured CSX on EMD much as the SD50 did in the 1990s.

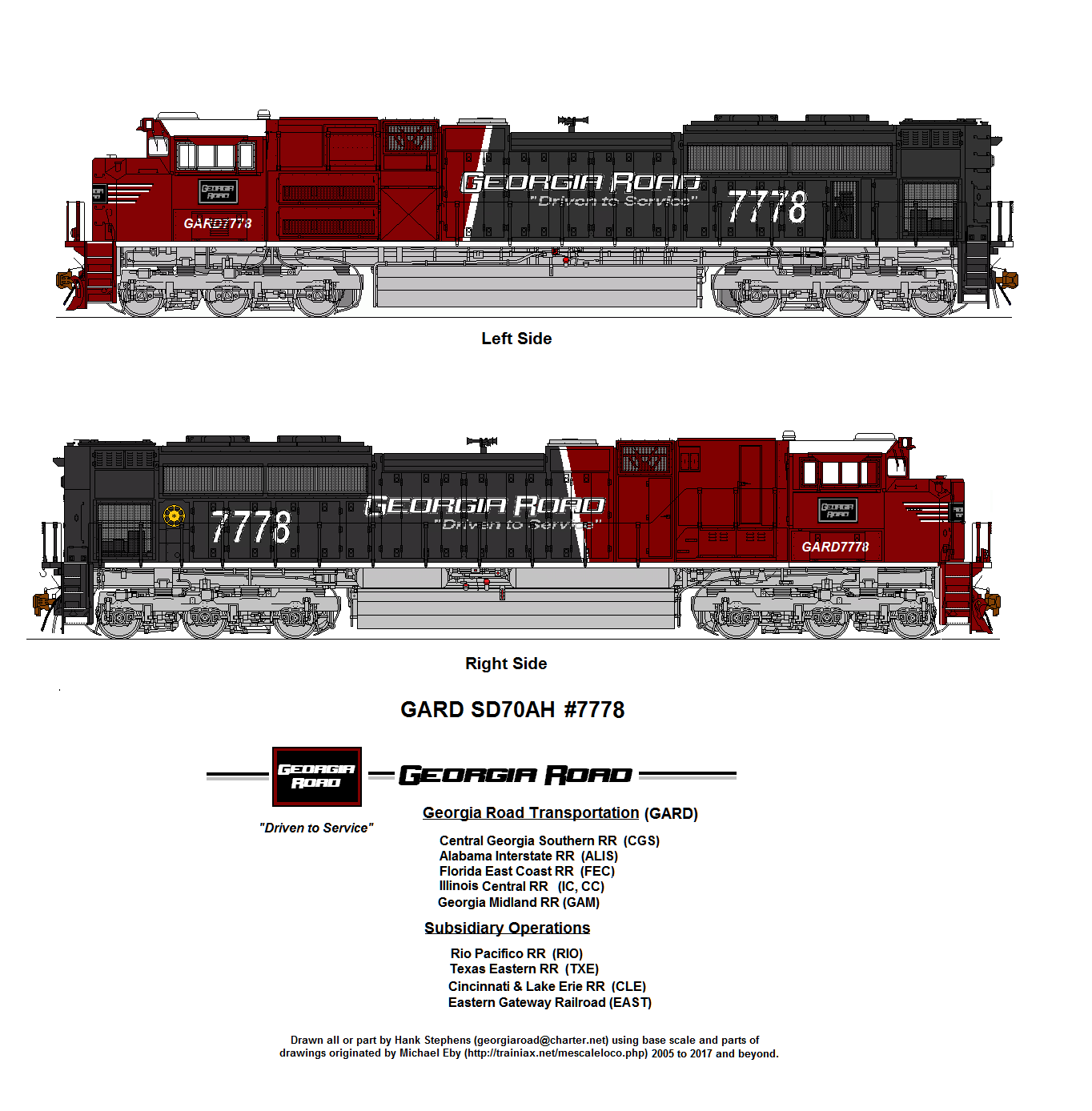

SD70AH

The Georgia Road SD70AH variants proved a vast improvement over early phase SD70ACe units and the CSX order of SD70AH as Georgia Road specified inclusion of the flexible isolation ability, upgraded isolated cabs and a beefed-up AC traction motor designed to prevent failures while dragging heavy trains long distances. Original order BNSF specification 7700-7724 units included isolated cabs and many of the upgrades that CSX missed in its early order.

Unit numbers SD70AH 7771 and 7778 represent the 50 units purchased in 2006-2008 with the thicker frame members, creating a heavier SD70ACe than typical (such as the first 25 units built to BNSF specifications). There are no visible spotting cues as to the difference between the first 25 units built to the BNSF specification and the later 50 units from the cancelled order of CSX SD70AH units that Georgia Road picked up. All the units have isolated cabs and upgraded cab sound proofing. The 25 SD70ACe units 7700-7725 were cycled back to EMD to be rewired for the single traction motor isolation ability and upgraded heavy duty traction motors like the SD70AHs. This made the SD70ACe units physically and mechanically identical to the SD70AH units other than locomotive weight from heavier framing steel and maximum tractive effort facilitated by the additional weight.

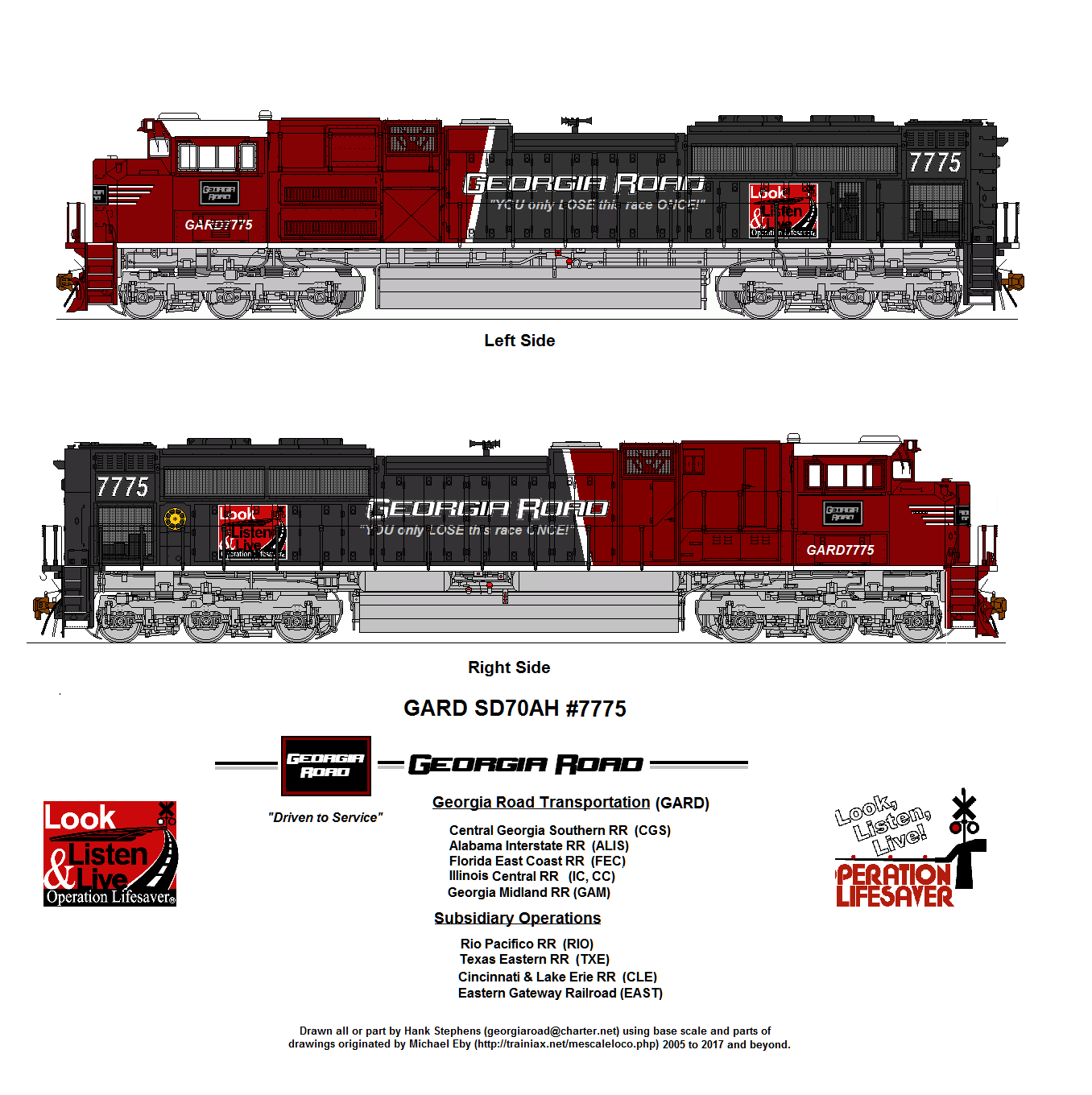

SD70ACe

Unit 7700 is the class unit for the series. This unit was the original order of 25 SD70ACes ordered by Georgia Road and tacked on to the end of a BNSF order. The units employed the isolated cab and improved vibration and sound proofing in the cab. These 25 units were initially assigned to the joint Powder River Basin Coal trains serving several Southern Company (SEEGCO) power plants in the Deep South. This early order of locomotives was assigned to the joint BNSF-GARD Powder River Basin SEEGCO coal train pool. The SD70ACe units regularly cycled with BNSF units from the Wyoming mines to East St. Louis, MO (BNSF leg) and the East St. Louis, MO to generator leg (GARD leg). When Georgia Road purchased the DME-IC lines and completed its own connection to the Powder River Basin, these units were cycled through EMD for upgrades to better match SD70AH power purchased two years later for the expansion of Georgia Road service all the way from the Wyoming mines to the Southeastern coal fired steam plants.

The 25 SD70ACe units debuted the winged logo on the nose which became standard on all wide cab locomotives after 2008. Several units received Operation Lifesaver graphics, including 7775 pictured above. The additional 50 SD70AH units (7730-7779) were also delivered in the now standard winged scheme. 7732, 7751 and775 were involved in a rear end collision while loading on BNSF near Thunder Mine on the BNSF Powder River Basin line. Two units were rebuilt as booster units and one was scrapped. As a result these three number slots remain open.

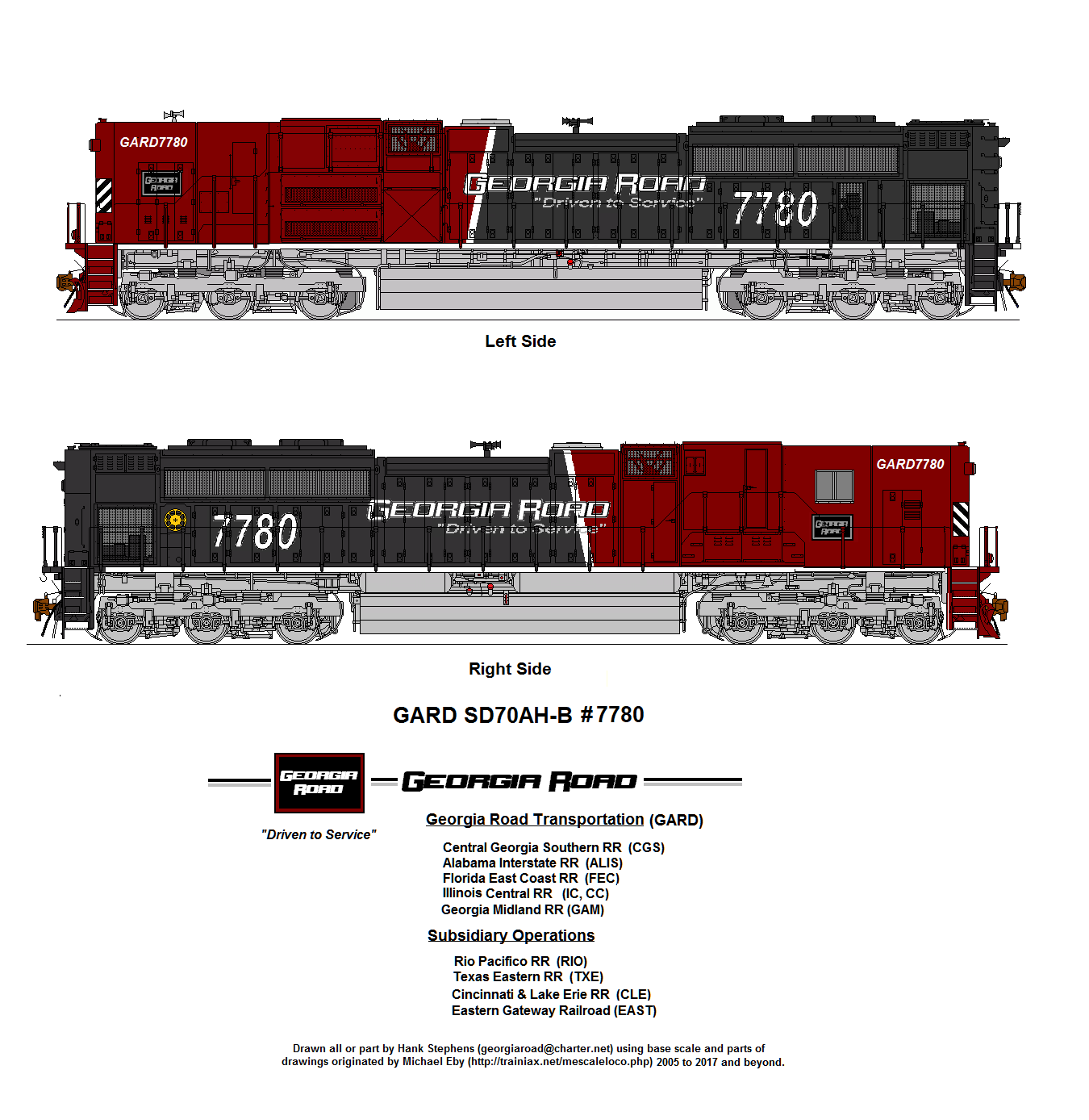

SD70AH-B

A rear end collision with a standing coal train on the Black Thunder Mine loading loop while being loaded by BNSF crews destroyed unit 7755 and severely damaged the 7732 and 7751. 7755 was written off on site and scrapped. 7732 and 7751 were sent to Stephens Railcar JTLS Locomotive Shops and repaired without cabs. These units were designated as booster units and were renumbered to B7780 and B7781. These units were repainted in a variation of the cab equipped units, setting them apart from most B units built as part of a rebuild program.

A rear end collision with a standing coal train on the Black Thunder Mine loading loop while being loaded by BNSF crews destroyed unit 7755 and severely damaged the 7732 and 7751. 7755 was written off on site and scrapped. 7732 and 7751 were sent to Stephens Railcar JTLS Locomotive Shops and repaired without cabs. These units were designated as booster units and were renumbered to B7780 and B7781. These units were repainted in a variation of the cab equipped units, setting them apart from most B units built as part of a rebuild program.