Growing up in the Deep South in the 1970s-1980s gave me plenty of exposure to pulp and timber related railroad business. The Seaboard Coast line (SCL) former Atlantic Coastline (AB&C line) was a quarter mile up the road from my home, and every road trip into town involved passing two sawmills that regularly loaded woodchips in oversized bottom dump woodchip hoppers at a place aptly named Lee’s Crossing. The crews nicknamed these cars “chip racks” likely a variation of the fact that pulpwood bulkhead cars of the time were called “wood racks” for the fact that wood logs were loaded in them. These were my first memories of trains, and my fascination with then would only intensify as I got older. Friends and I regularly walked the railroad in pre-teen days on “adventures”, winding up at the sawmill spurs in Lee’s Crossing where we poured over every inch of the cars. Cars ranged from builder fresh with the new Family Lines System logos, to worn predecessor roads such as L&N, ACL, WofA and early SCL. Many times, we were there when the SCL local came calling, We excitedly watched as the local crew deftly swap loaded “chip racks” for empties. The smell of pine rosin was everywhere, mixed with creosote from the ties and diesel exhaust as the local worked the chip loading spurs.

I tell my model railroading friends I have what my spouse refers to as a “compel-shion” with trains, particularly woodchip car models. In moments of reflection, I find it fascinating how such formative memories at Lee’s Crossing come back to influence modeling in later years. I grew up with the industry, and as I got older, collected anything I could on woodchip cars and related operations. I still do so, as the video below illustrates,captured recently via Virtual Railfan Cordele PTZ Railcam.

A Heart of Georgia GP38-2 pulls a string of loaded Greenville woodchip cars over the CSX-NS-HOG diamond in Cordele, GA in 2023. GWI owns not only the HOG, but the Meridian and Bigbee (MB and MBNR), Georgia Central (GC), Apalachicola Northern (AN) and Bay Line RR (BAYL). A mix of Greenville cars from AN and MB are headed from a sawmill at Preston, GA to the CSX interchange at Cordele.

OVERVIEW

Fast forward to current day and my modeling aspirations are no surprise. I model prototype freelance, specifically the Georgia Road Transportation in HO Scale. This modern Class one still has a deep connection to pulp and timber business as evidenced by its substantial woodchip car fleet. The epitome of the Georgia Road woodchip fleet is the Greenville Car Company 7000 cubic foot bottom dump high cube hopper in the concept drawing below During the time period of my “adventures” and later railfanning as a young adult, these were the ubiquitous replacement cars for all the myriad of custom and modified hoppers that supplied the modern woodchip industry from the beginnings in the 1960s. Sawmills switched from discarding or burning waste to selling it to local paper mills. In the early 1980s, many railroads attempted to standardize the car fleets to suit modern paper mill operations and to standardize shipping rates. This purpose-built car could move substantial amounts of chips in a modern and standard form, reducing cycle times and increasing utilization.

Along with updating sawmills to ship, rather than discard or burn pulp waste, paper mills found the woodchips to be a way to bypass some of the prep work of stripping and grinding logs and pulpwood at the plant. Most paper mills of the time used “stick” length pulpwood,. These eight-foot logs were based on what two men could handle and load by hand onto pulpwood rack cars. Later loading machinery using modern hydraulics replaced the manual labor substantially. Chipping mills also sprang up, allowing pulp to be handled in an unrestricted form from multiple regions, with trucks bringing tree length logs that would be unloaded, stripped, chipped and loaded into waiting woodchip cars. The cars could be quickly dumped at the paper mill with the contents able to go directly into the papermaking process. Cars could cycle in closed loops quickly, and with enough cars in a pool, could support paper mills several hundred miles away.

All of the Deep South Class One railroads kept large fleets and most of the “timber centric” short lines had their own captive purpose-built woodchip cars. Typically, pools were controlled by the assigned destination paper mill and cars never deviated unless the destination mill changed or closed. Most chipping plants were owned or were subsidiary companies of the paper mills they served. As cheap import pulp flooded North American markets and environmental rules became more stringent in the 2000s, many paper mills closed in favor of smaller conversion mills processing imported fluff pulp or container board or paper rolls made overseas and shipped to the US. Railroads shied away from the business also, as return on investment moving woodchips and pulpwood was breakeven at best. What was once was a traffic segment ubiquitous to the South, was retracting at an alarming rate in the 2000s. Trucks replaced rail, which seemed counterintuitive due to fuel costs. Smaller mills that could no longer meet minimum requirements to ship by rail, and unless linked by a captive short line, lost rail access. Large chipping plants were sold and became contract providers. Due to their ability to produce in large quantities, some modern woodchip operations were preserved. By the late 2000s, class one railroads sold their aging fleets of woodchip cars to third party leasing companies or scrapped them. Paper mills closures and rationalization of the industry left only large operations managing to keep rail service by 2018, which continues today.

In terms of my prototype freelance Georgia Road, the pulp and timber segment has seen a metamorphosis of sorts. Pulpwood has come and gone, with the only log hauling on converted bulkhead cars remaining. This segment primarily hauls veneer logs (plywood) or tree-length for dimensional and framing lumber long distances to mills where local resources are “logged out” or cannot support larger consolidated mill operations. These moves are isolated to closed loop runs from log load outs to fixed destination mills.

THE INDUSTRY–PROTOTYPE AND MODELING

Southeastern woodchip railroad business comes in two forms, the chipping plant and the traditional sawmill operation. Both produce woodchips. The chipping plant is purpose built to create woodchips in large quantities to supply regional paper mills. These are located some distance from the mills, usually in areas where timber reserves are plentiful. These mills are relatively simple in design and can be up and running in a short time. Logs are brought in by truck and unloaded by log cranes. These cranes stage logs and feed the debarker/chipper. Bark stripped from the logs is loaded on trucks for sale to the landscape industry or in some cases, burned for power. Woodchips are loaded into strings of woodchip hoppers and moved by rail to the paper mills. Some mills rely on these outlying chip plants to supply the bulk of their input woodchips. Larger paper mills often time use these plants to augment wood brought in by truck locally.

Sawmill operations produce woodchips and finer saw dust as a way to control waste and increase profitability. The woodchip stream is clean and due to the logs being debarked before cutting into lumber. Excess wood tops and ends are ground into chips as the lumber is cut and loaded during the process., referred to as saw waste or what it calls “slash”. Tree length logs are delivered by truck where they are sorted, debarked and cut to rough length. Bark is either burned to generate steam for the drying kilns or sold to the landscaping business for composting or dressing. In the 1980s, the general industry view was that the sale of woodchips to paper mills made the operation profitable.

In years surrounding the 2020 Pandemic, the lumber industry experienced exponential demand due to consumers having both money and time to build. Demand for housing due to rock bottom interest financing rates only encouraged demand to historic levels. This put unprecedented stress on the modern lumber market and pushed prices to highly profitable levels, encouraging sawmill expansion. Loss of global supply chains boosted domestic pulp and paper production which temporarily increased the demand for woodchips. Many sawmill operations resurrected rail-borne chip loading, and those still using rail expanded loading woodchips on railcars. By 2024, demand dropped off as inflation and higher Federal Reserve rates slowed demand. NS and CSXT both disposed of their woodchip car fleets, repurposing some (CSX coke car conversions) or selling cars to leasing companies, papermills or short lines. Woodchip business was relegated to specific closed pools, short line hauls and in many cases, summarily ended to the chagrin of the mills utilizing them for loading.

The Deep South has seen a renaissance of sorts in new sawmill operations as high demand and record profit margins spurred stagnant dimensional lumber production to expand. Abbeville-based Great Southern Wood built a brand new saw mill at Abbeville to supply treated and white lumber during the Pandemic of 2020-2022. While still in operation, production has dropped with demand in 2023. It will remain and likely replace older mills that lack modern efficiencies if the market fails to recover. GWI -owned BAYL services the mill. Woodchips went to the CCA papermill at Panama City, FL until its closure. Now chip cars are leased, and appear in irregular cycles as woodchips have to be sold on contract. The BAYL captive fleet was sold to GATX Leasing after the GWI takeover as seen on the right in the picture. These cars were re-sold again when the CCA mill closed and left the property.

THE MODELS

Woodchip business is still strong on the Georgia Road, mostly due to a focused attempt to stream-line the business using a network of chipping plants to supply remaining open paper mills. The exit from the business of all the local Class Ones has left the available woodchip fleet as a whole, thin and lacking. Georgia Road linked the push for reduction in greenhouse gases by offering pools of rebuilt and new cars to supporting the raw timber and pulp business segment. The aim is to reduce long distance log hauling by trucks, while providing modern equipment and a commitment to support long term business in a “greener” form due to the inherent efficiency of rail transport.

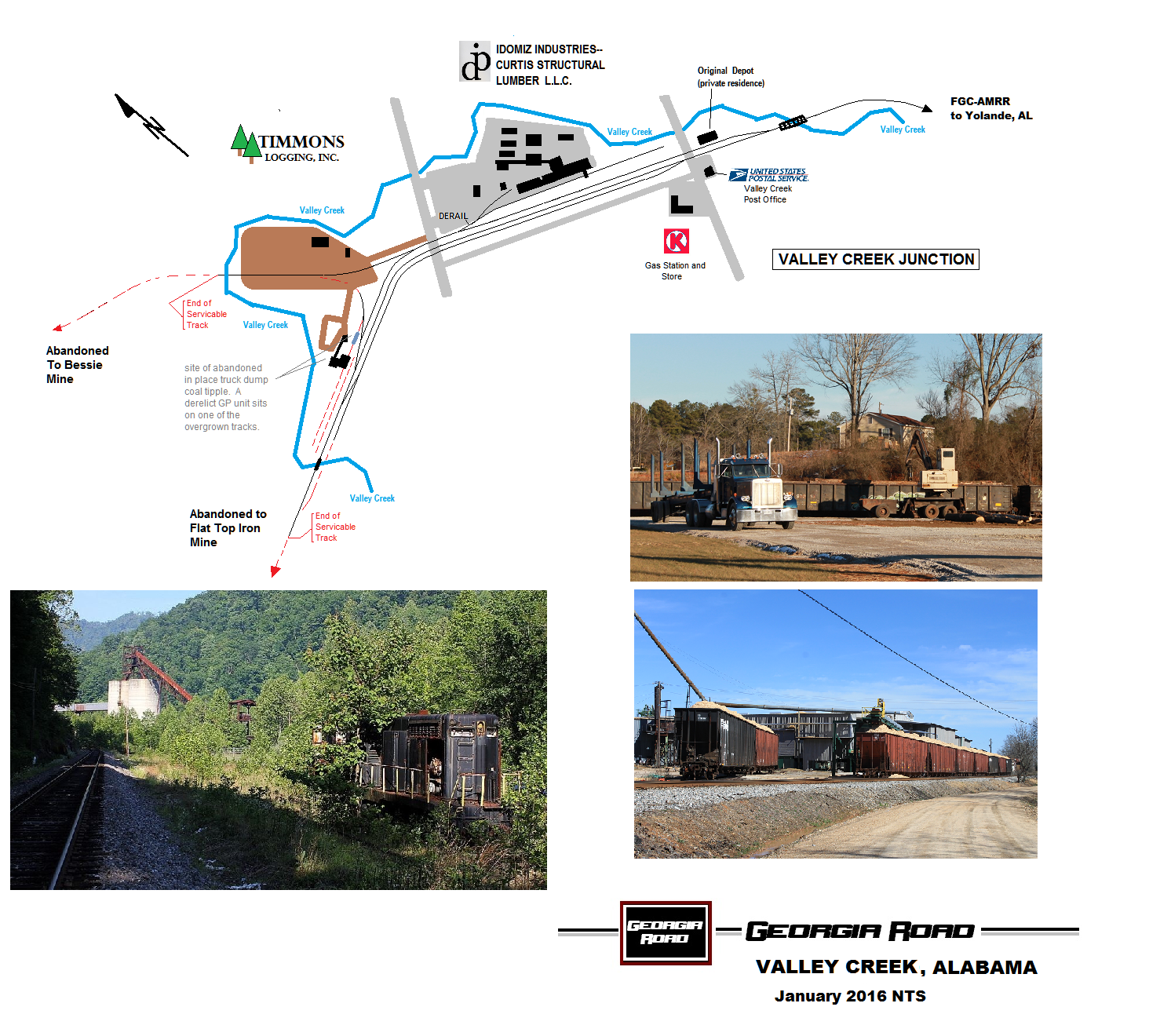

The basis for the HO Scale Georgia Road layout is set in my experiences, one of which is the Lee’s Crossing sawmill spurs and switching operations. While names and exact details are altered to fit my concept, they emulate the very scenes I picture in this article and remember growing up. For example, the end point town of Valley Creek is home to a modern sawmill operation dedicated to a good friend and fellow modeler Damon Curtis. The actual logos are taken from his self-titled Christian Hip-Hop Production Company. Damon and I have spent hours poring over paint schemes and layout plans and his inspiration is a critical part of the concept featured on this website. This is my way of showing my gratitude for his help with all the mind-numbing details of pulling a prototype into a freelance. I encourage those interested to check him out. He is a great person and equally fine musician. https://www.idp-music.com/

Looking closely at the site plan and layout design element above. The namesake Idomiz Industries– Curtis Structural Lumber is actually the rough layout of the Dudley Lumber Company prototype featured in this article. Rather than being located on the main line, the mill is sitting on the end of a former coal branch, abandoned just past the Curtis Mill. The remains of the old junction yard make for some interesting switching problems as trains have to use saw-by maneuvers to switch and run around the train before heading back to the base of operations at the Georgia Road mainline in Yolande, AL. The actual branch and defunct mines are prototype, all abandoned in the late 1980s when Drummond Coal ended domestic production and moved to South America. A log yard and the remains of a defunct truck-load coal dock with an abandoned switcher add to the scene.

While I have yet to begin building any appreciable track plan, I bide my time creating the locomotive and rolling stock fleet to support the various operations on the layout, including the woodchip car fleet that will service the Curtis Mill at Valley Creek.

Greenville 7000 cuft cars comprise the largest class of woodchip cars in the Georgia Road Fleet. The entire fleet was rebuilt and strengthened for rotary service. — Walthers model stripped, repainted and custom decaled into the standard woodchip car scheme.

The Georgia Road increased its fleet in the 1990s and again in 2023 with FreightCar America (formerly Johnstown America) 7800 cuft rotary dump cars.—LBF/Hubert’s model with replacement trucks, couplers and reweighted

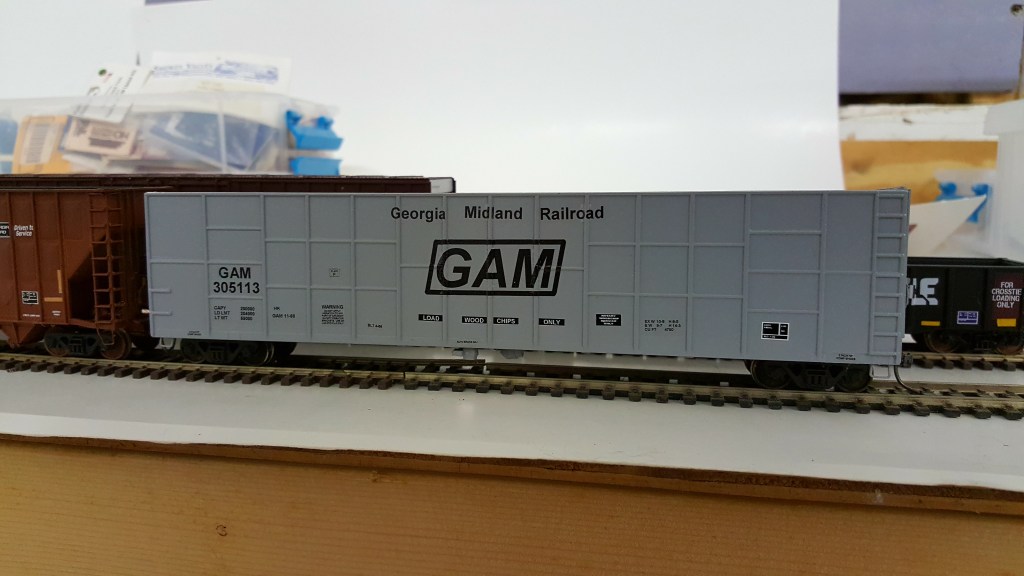

A gray predecessor painted GAM rotary car built originally for SP by PACCAR This class had its end doors replaced with fixed ends and car was strengthened for rotary dump service.–E&C Shops model with new trucks, couplers and weighted interior.

A re-stenciled Tangent model of an outside braced woodchip car carries reporting marks of lessor Stephens Railcar Leasing (SRCX) and augments Georgia Road owned cars in pools.