Background and Motivation

It is funny how time flies when so many things tug at personal free time. In my own act of desperation coupled to a little too much hubris, I took on the task of a major remodel at the house we purchased a couple of years ago. The personal effort at remodeling was done to control sky-rocketing costs. While I am capable, my efforts were and continue to be both long and slow. The downside as a modeler is my endeavor swallows up most of the hobby time. To my chagrin, I reduced from modeler back to collector. This is a dangerous place for anyone attempting to build a finished layout. The only redeeming feature in this current state of affairs is planning, since work can be strung out for days and weeks, even approached at random as time permits. There is a proverbial silver lining, as the “drill down” becomes very detailed, even to the point of delving into operation.

Research around layout planning is one of my interests, and I work my modeling trade around the idea of Layout Design Elements, or LDEs. As with many large railroad modelers, the space requirements dictate the compression of sometimes hundreds of miles of railroad into limited square footage. Choices have to be made to optimize operation and at the same time create a complete expression of the layout concept including the distance that is compressed. The redeeming nature of my own attempts at LDE design is it lends itself to a complete cycle of researching the prototype, extrapolating the freelance, and designing a plausible prototype freelance design complete with plausible operation. These mental games in written form not only act as guideposts for future construction but also dictate what locomotives and rolling stock needed for the operation of the LDE one built. Trains will be ready immediately when the layout is functional as I can acquire and build trains based on the LDE concept requirements immediately. Spatial and benchwork structure design can also be approached with a better idea of how the LDE will fit into the overall operation of the yet to be built layout. My mental “games” identify many problems at the start, rather than being beholden to complete trial and error down the road. The ability to actively model without a layout is also part of that silver lining. For those following my website and to a lesser extent my Facebook page, I delve into LDE design in a series of articles. Most are directly focused on the Georgia Road concept and layout to be built as permanent design notes, but I attempt to provide detailed research in hopes it is useful as inspiration to other modelers. There is a concerted effort to take the reader from real prototype operations to a cohesive prototype freelance layout operation mimicking actual prototype. This “mental modeling” sustains my interest, though time constraints make full pursuit of documentation its own long-term exercise.

Inspiration from the Prototype

As projects go, some take the forefront as other settle back into completed obscurity. In this case I found myself looking at plausible industry and potential operations on the Georgia Road Alabama Interstate Division. After the great recession of 2008-2009, I found myself unemployed and abandoned by the textile industry that I literally grew up around and worked in as an adult. I was forced to return to school and find a new career as textiles were fast moving to other countries, leaving long term opportunities in the empty mills that once supported a complete local economy. At the time, South Korean OEM KIA Motors Manufacturing (KMMG) ramped up to full production at their automotive assembly line in West Point, Georgia near my home. I watched from the sidelines as the plant was built over several years and even documented the start of limited rail operations. As luck would have it, I became a supplier representative at the plant and learned the operation from the inside out also. Later I would work a year with a Honda supplier near Talladega, AL for the Honda Assembly Plant in Lincoln, Alabama. As I traveled back and forth, I managed to document operations at the CSX TDSI automotive loading ramp and unrelated CSX and NS operations in the area. The more I watched the operation over time, the more fascinating it became.

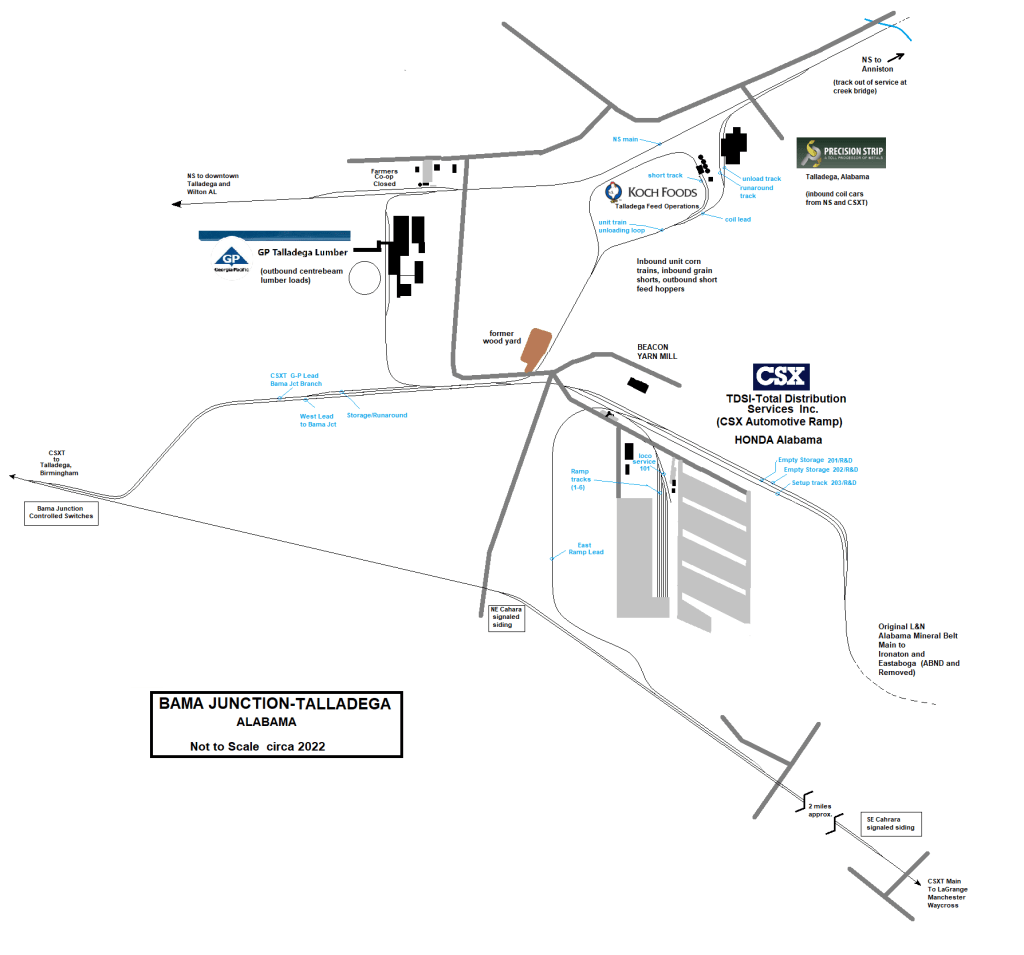

CSX managed to spirit away the Honda outbound autorack business from NS in a novel way. At the time, Honda was adding additional assembly lines to the main plant 40 miles north of Talladega. They decided to take in the space occupied by their current autorack loading area, which was historically served by NS from their adjacent NS Birmingham to Atlanta mainline. CSX convinced Honda to allow them to service the business instead, agreeing to build a new ramp beside their own Waycross to Chicago Lineville Subdivision mainline. Honda purchased a fleet of natural gas fired auto carrier trucks to move all the cars from the production lines in Lincoln the 40 miles south to the end of an old L&N branch line east of Talladega. CSX built a complete automotive loading ramp under its subsidiary, Total Distribution Services Inc (TDSI). While TDSI was placed right beside a major CSX trunk line, it was also on the rural and somewhat remote side of town. The old L&N branch left the Lineville Subdivision at Bama Junction closer to downtown Talladega and ran about three miles to serve a Georgia Pacific plywood mill and log yard before disappearing into the overgrowth and ending. The tail of the branch was used mostly for car storage. When G-P decided to idle the plywood mill in the early 2000s, the branch looked like its days were numbered also. Koch Foods decided to build a chicken feed mill and distribution plant off the branch and Honda supplier Precision Strip located nearby to process coil steel rolls for the Honda production lines at its Lincoln Assembly Plant. The branch would see a revitalization of sorts, as cuts of coil steel and shorts of protein enhancer grain loads jointed weekly unit trains of corn serving the two new industries.

TDSI joined an eclectic group of industries in the revived ad hoc industrial park several months before my tenure at the Honda supplier. I was able to see the actual beginning of full operations. Also, during the time, the post COVID-19 building boom made Georgia Pacific reconsider its plans to sell or scrap the plywood mill and instead convert it to a state-of-the-art structural lumber mill. Koch Foods was also ramping up business at the brand-new feed mill and Precision Strip was supplying KIA and Hyundai as its portfolio of customers diversified. NS had its own branch serving Precision Strip and the G-P plywood mill within eye shot of the CSX Bama Junction branch, with trains running as far as Precision Strip, before doubling back to their terminal on the west end of the line at Wilton, AL. In short, this four square mile area juxtaposed CSX unit hopper trains circling the feed mill in the middle of a cornfield, CSX unit autorack trains built by contract switchers moving out of the TDSI facility and structural lumber shipped on CenterBeam flatcars from Georgia Pacific while NS supplied coil cars to Precision Strip at the end of its own line. All of this was wrapped in rural farm and pastureland east of Talladega proper, making for a remote a rural feel when no trains were moving.

Some of the notable operational details of the “East Talladega Industrial Park” was both how it was laid out and how it was worked. The construction of the Koch feed mill lead was built literally on the spur end of the old Georgia Pacific log Yard just east of the G-P mill. During the 1980s, this yard was the staging point for veneer logs going into the Georgia Pacific Plywood Operations Talladega Mill. Railroad log cars and highway trucks unloaded at this yard where the logs were sorted, graded and staged. A series of intra-plant trucks moved logs to the actual mill less than two football fields away. The old branch line main continued east and was a convenient place to store log cars, woodchip hoppers and boxcars cycling through the plant. A local switcher based in nearby Talladega worked the mill on a daily basis. As Oriented Strand Board (OSB) gained popularity as a cost-effective substitute for plywood, Georgia Pacific closed the mill in the early 2000s.

The mill and log yard sat empty until 2017 when Koch Foods built its new feed mill in the middle of a large cornfield just north of the old log spur and tied its unloading loop into the old branch using the log yard lead. TDSI would be built on the remaining branch line only a few short years later. During the TDSI build, a second parallel track was built to allow contract switching locomotives and CSX trains to drill the ramp lead without fouling trains working to and from the feed mill. As an aside, a lead was also added behind Precision Strip to potentially connect NS to the mill if needed. CSX autorack trains operated both north and south, so a connection track was built at the neck of the TDSI faculty to allow trains access in either direction forming a rather large wye. Holding tracks for the ramp were built on the original branch line right of way, even resurrecting part of it to allow capability of swallowing 75 plus car unit autorack trains.

Georgia and Alabama in particular have seen exponential growth in poultry farming as American appetites for chicken and turkey continue to grow. All these birds have to eat, and as a result feed distribution requirements have increased accordingly. Koch Brothers is one of the larger players in the region, and two new feed mills were built in Alabama in the last few years to meet increased feed demand. Happenstance caused by my consulting job allowed me to observe The Talladega mill regularly due to its adjacent location to TDSI, and over time I learned how the minimalist track plan worked. The CSXT served business was built in the mid-2000s. The multistory concrete structure blended train loads of corn with protein boosting supplemental grains to create feed which the plant loaded in trucks for delivery to poultry houses in a hundred-plus- mile radius. Dedicated unit trains brought corn, while “short” loads of soy and other additives were delivered by the Talladega Road Switcher based in downtown Talladega.

The feed mill was constructed at the end of an old L&N branch line which had been cut back to a closed Georgia-Pacific plywood mill about a mile from its connection to the CSXT Lineville Subdivision (ex-ACL, nee-AB&C) mainline at Bama Junction. This was formerly part of the old L&N Alabama Mineral Belt that circled the Birmingham, AL region, meandering east then north to Anniston, AL. The L&N Alabama Mineral Belt connected coal, ore and quarry operations to steel and foundry operations in Birmingham, hence the Mineral Belt name. When L&N became part of the CSXT system outright in the mid-1990s, the Mineral Belt was rationalized and reduced as steel-making waned and better routes rendered it redundant. The line east from Bama Junction had no industry and no traffic to forward around the east side of Birmingham to Anniston so it withered and died, with the first mile left in place to service the G-P mill which was still a going concern at the time. A nearby pulpwood operation finished out the remaining active industry with it also succumbing in the early 2000s as rail handled stick wood fell out of favor, substituted by truck hauled tree length stock. The G-P plywood mill ended production in the deep 2008 recession, and the remnant branch became nothing more than a storage spur for the CSX Talladega Local to stash cars out of the way.

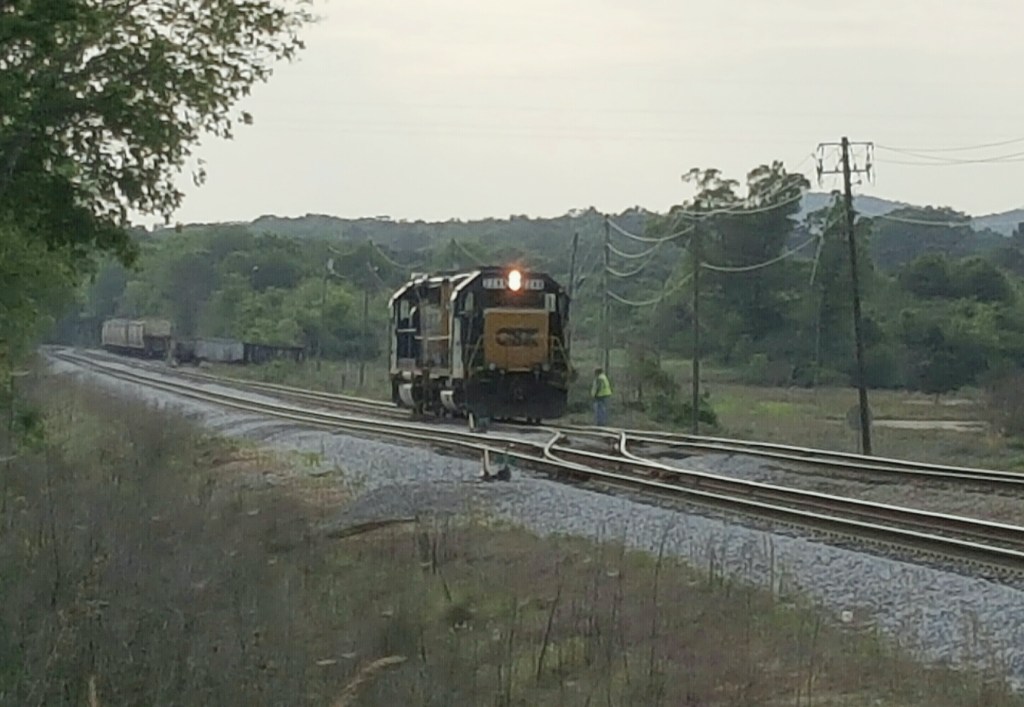

On my regular trips, I arrived to find nothing moving on some days, only TSDI doing switching or in one in evening seeing the convergence of inbound and outbound CSX intermodal trains as a unit grain train arrived. Occasionally, I managed to catch the CSX Talladega Switcher moving shorts of single covered hopper loads of protein enhancers at the mill. Due to my schedule, I rarely saw the unit grain train actually unloading. It appeared that the trains would arrive one day, unload the next and wait for a crew to take the train back to the CSX mainline and north to Birmingham.

The notable takeaway from my experience railfanning was the irony of modern era automotive, chicken feed mill and existing timber production operations all in the same rural area. Trackwork was minimalist and linear for the most part. I could not resist the idea of using this prototype in my own layout design concept. Much of the operation could be represented by implied leads and well disguised staging tracks in the backdrop such as the actual TDSI ramp. The unloading loop could easily sit on the top of a helix as a scenic disguise. Unit autorack and grain trains were regular players. Two local switchers also regularly worked the area also. As a result, I spent time documenting the operations over time hoping to integrate what I had seen at some point as I planned my Georgia Road layout.

From Prototype to Freelance Design

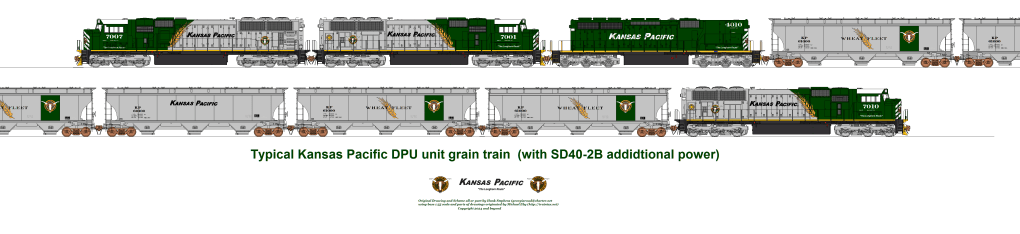

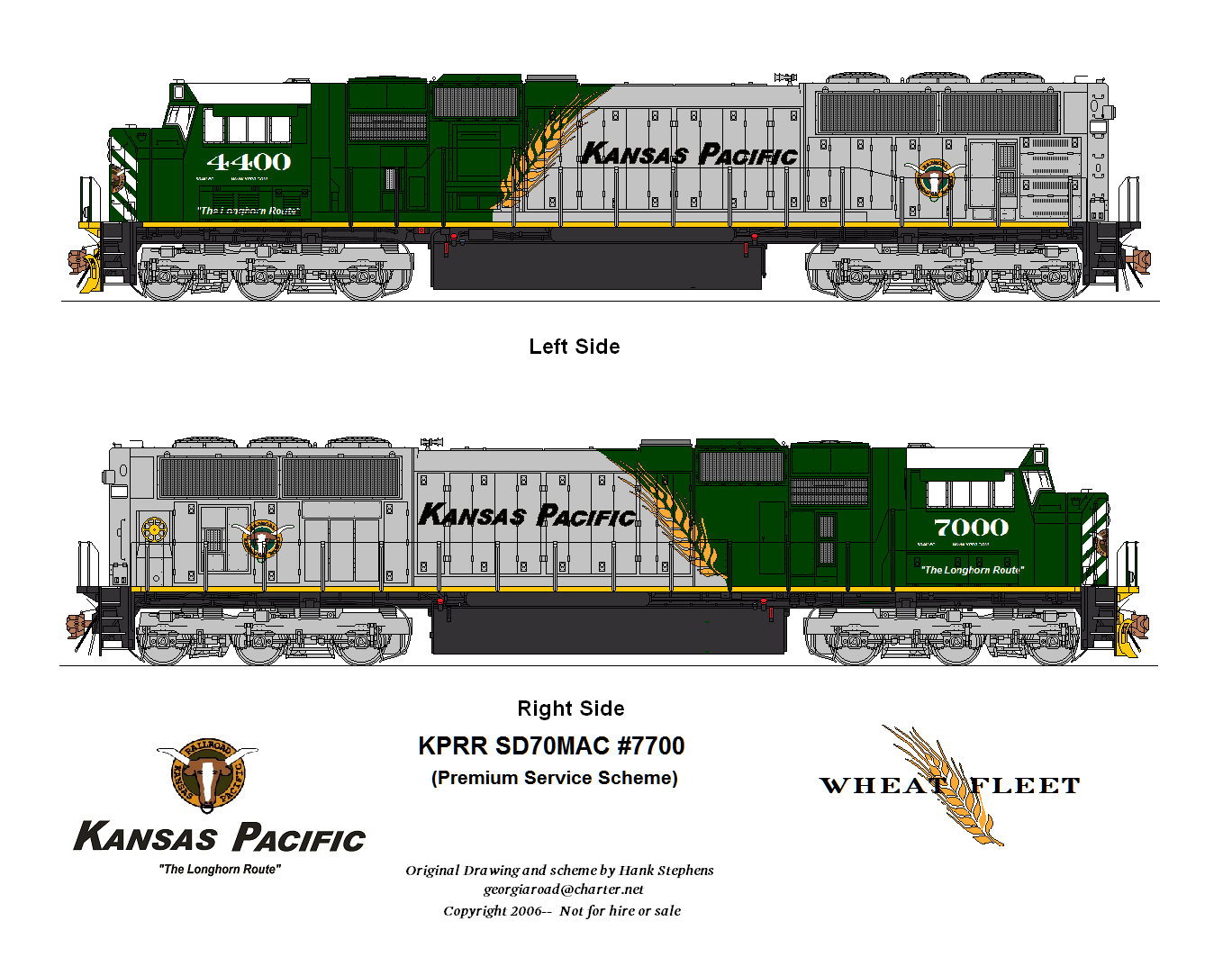

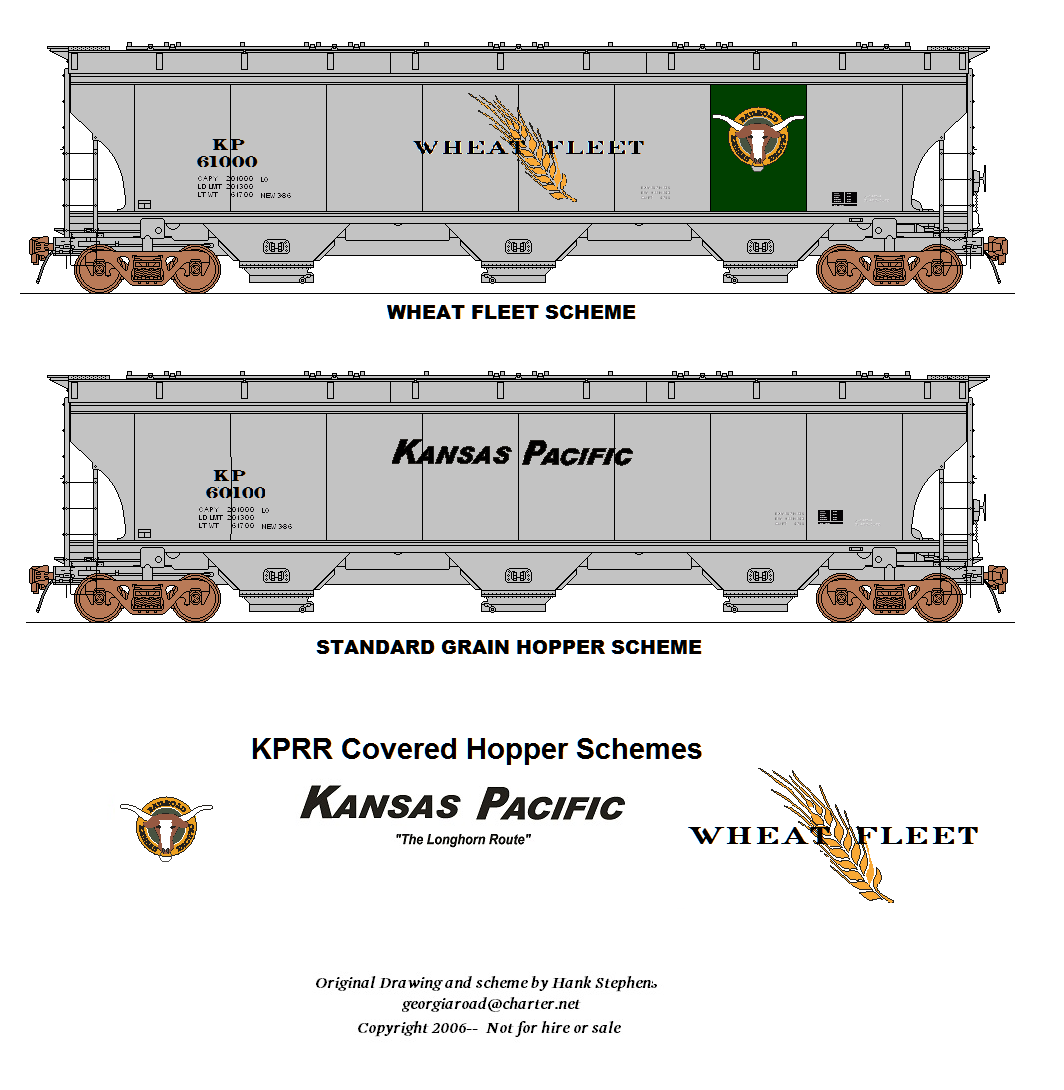

I did not give much thought to the Talladega operation following my tenure end at Honda. I was soon working at KIA again and other than archiving all my videos and pictures, did little to further a layout design element or actual plan. This would change during conversations with fellow modelers Anthony Lorch and Joe Bohannon. I helped Anthony Lorch design paint schemes and logos for his Kansas Pacific Railroad (KP) including the idea of the “Wheat Fleet” branding for the unit grain operation that made up a large portion of KP operations. Anthony’s operational knowledge base as a Union Pacific conductor proved critical in my own understanding of midwestern and southwest traffic patterns which revealed the other side of western grain harvest and collection by railroads for customers back East.. His KP concept related well with my own Georgia Road ideas, and the KP was a natural connection from the West to feed traffic to the Georgia Road at Kansas City. I passed the idea by Anthony to have an actual KP grain train either passing through my layout design or actively taking part in it at some type of grain related industry. “Beyond the Basement” idea coined by famed prototype freelance modeler, Allen McClelland of the Virginia & Ohio (V&O). Joe Bohannon, who was also developing his Chinook Lines prototype freelance at the time, became a sounding board as I recounted the Talladega operation and my desire to model it. He self-financed his own run of Chinook grain cars around the same time for unit grain trains originating on his Chinook Lines. After seeing them, I was hooked and managed to talk him into allowing me to purchase several. I figured these would be filler cars on Georgia Road freight trains to establish a concrete link with his Chinook concept that also would be a major Georgia Road interchange partner in the Northwest.

I would fatefully cross paths with Christopher Palmieri, who also was an avid prototype freelance modeler. Initially I helped do some design work for his own Meridian Speedway group of prototype freelance railroads. Soon after, he launched HOMESHOPS LLC, based on the idea of creating factory produced freelanced cars for open purchase of current and well-known freelance railroad design concepts. He was interested in finding subjects for his first run of cars. He was familiar with my Georgia Road, Anthony’s Kansas Pacific and Joe’s Chinook Lines due to posts on several forums and Facebook. Artwork I helped design for the KP would manifest itself in a release of Tangent Models covered hoppers. I immediately started ordering the KP cars to build a unit grain train that I imagined would originate on the KP and unload on the Georgia road, mimicking the Talladega operation that was latent but still in my mind. I collected several of the other initial offerings by HOMESHOPS LLC to represent the short shipments of protein enhancers used to make finished feed. While CSX unit trains provided the corn in 75 car deliveries, the short order enhancer grains came in handfuls from various shippers and railroad owned cars. When added to my Chinook Lines cars, I had the beginnings of a feed mill operation that drew in not only my Georgia Road, but the freelance concepts of my friends and acquaintances.

Ongoing conversations with Anthony and Joe helped me flesh out a similar Georgia Road operation that could be realistically modeled. Bouncing the ideas off fellow freelance modelers gave me the interaction with likeminded individuals and challenged me to step up my own game. They patiently listened as I laid out ideas and gave me valuable insight from their own perspectives to help me hone my general ideas into a plausible layout design element which seamlessly linked to their respective ideas. I eventually had enough Chinook and Kansas Pacific cars to field a 18-25 car unit grain train and the necessary intermittent short cuts of protein enhancer loads to accurately model the Koch Foods mill. While expensive, this factory painted trainset saved long hours of work. Chris Palmieri, through his offerings, brought the train to fruition ahead of my own original plans of spending months hand decaling enough cars to facilitate a freelance version mill. Instead, I could shift concentration on operation and physical design with trains ready to run once the layout was physically. Since the Georgia Road layout is still many months out as I build a building for it, I could model regardless of my limitations. The looming question for me was, “how does one mix all these related details into a concise plausible LDE that operated like the prototype in Talledega?”

The first step in creating the LDE is knowing the type of equipment that will populate it. With all the collected grain cars, I had the basics. at hand. Georgia Road could theoretically pull unit corn trains from its own Midwestern lines, from the Kansas Pacific and also the Chinook Lines. I could field grain trains from all three sources. In the initial design patterned after the covered hoppers I collected; The Kansas Pacific Railroad would send run-through unit corn trains complete with KP power. The Georgia Road L26 road switcher assigned to the area would bring in the protein shorts, allowing me to use any grain car I wanted similar to the mix observed on the CSX Talladega Switcher when it worked Koch Foods between unit grain trains.

While more recently constructed feed mills use balloon tracks for unloading as I learned, most existing mills constructed until the 2000s required trains to be switched in and out. They usually employ switcher locomotives or car moving “critters” such as trackmobile units. Most of my railfan experience was around these linear type operations and I originally planned to use this form, since it could easily be set running against a wall. I found a great example of the linear feed mill is the Pilgrims Pride operations located in Waco, Georgia on the NS Birmingham, AL to Atlanta, GA main line known as the East End District. The facility works much like the Koch Foods example, but trains are broken down into a stub yard behind the mill and pulled by a switcher through the unloading shed.

Work at the feed mill can be more than unit trains in and out. Short loads of protein enhancers such as soybeans and cereal grains and meals are mixed, ground and even cooked to create the finished product. Feeds are made primarily of corn which is mixed with appropriate proportions of cereal grains, meals and minerals required to raise healthy birds. With corn making up around 80 percent of the mix, it comes in unit trains. Other additive components may arrive in standalone single and short block hopper shipments outside of the unit grain trains. These cars have to be segregated and unloaded separately. If the mill supplies small distribution facilities outside of its region, finished feed has to be reloaded into segregated covered hoppers for independent rail shipment.

The lure of doing something different kept me coming back to the Koch Foods loop in Talladega. Of the two prototype configurations, this would be the most difficult of the two to represent, as the loop would take up a much larger and closed footprint. During my research on Koch Foods, I found out they were in the process of building a second plant near Attalla, AL about two hours northeast of the Talladega operation. This mill was on the opposite side of Brimingham from the modeled portion of my Brookwood Subdivision and was part of an expansion into North Alabama. Chicken houses were being built all around North Alabama, and Koch Foods wanted to capitalize on the new business and increasing demand.

The intriguing observations looking at both the architect rendering and the drone image by Josh Putnam was the simplicity of the track arrangement. The footprint of the plant was held to a minimum by placing it inside the loop. This is likely due to the hilly nature of the area as it sits in the Appalachian foothills. It is large enough to handle the unit corn train with little wasted space. Notice in the drone shot the locomotives have circled around to the tail of the train. After running counterclockwise to unload straight off the mainline switch, the locomotives only have to uncouple from the train, advance a few car lengths to the rear of the train and couple to it. After switching leader cabs and the EOT, the empty train is ready to depart for the next trip to reload. Much like the road switcher at Talladega, the NS Attalla Switcher brings in any short single loads of feed enhancers. These are unloaded and retrieved on the days between unit train arrivals. With a little “freelancer license”, I could relocate this operation to my modeled area around Brookwood with similar terrain and construction. I have two helix structures in my layout design to move trains from overhead staging to one of two levels. I also have long loop peninsulas in the design that would give me the space needed to create this operation. More about that later.

While the feed mill operation was in itself an anchor industry due to its unit train operations, I found I wanted to also include some of the other aspects of the Talladega prototype. There was just something attractive about the unit grain and unit autorack trains literally working side by side. Fortunately for me, my modeled area places my Georgia Road mainline near the actual prototype Mercedes Assembly Plant in Vance, AL. If I located the feed mill nearby, I could easily duplicate the juxtaposition I witnessed at Talladega. I would not be trying to model the prototype specifically but waned to adapt it to my own layout design aspirations. So how in the world can one place two large footprint industries so close together without dedicating large amounts of square footage or modeling? The answer was very close to home, ironically.

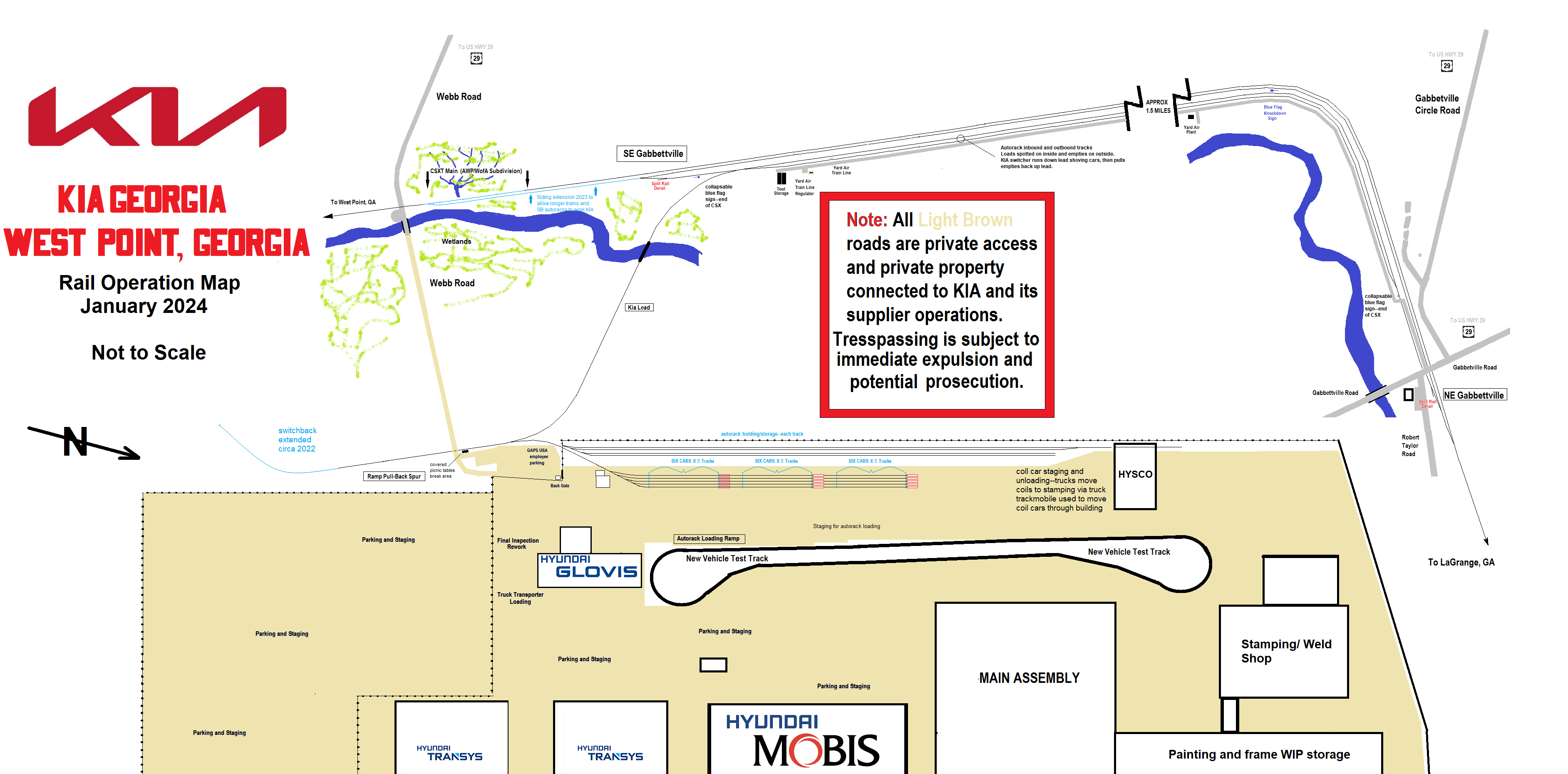

As I mentioned earlier, I began my new career working as a contractor for a KIA supplier near my home in West Point, GA. I got to witness the KIA assembly plant go from original groundbreaking, to start up and even eventually seeing the operation firsthand due to my job. KIA was one of several foreign automaker companies building in the Southeast during the 2000s. BMW, Mercedes, Honda, Hyundai, KIA are just a few that dot the map in Mississippi, Alabama, Georgia and South Carolina. A horde of suppliers followed, and now automotive is big business in the areas once dominated by textiles. These plants are smaller, flexible and rely on containerization more than traditional rust belt operations I watched around Atlanta in the 1980s. Even so, Automobile manufacturing has an expansive footprint.

Traditional operations in the rust belt of the Great Lakes region have tracks running everywhere and facilities that sprawl for miles. In most cases, modelers either dedicate a large sum of modeling to replicate these assembly plants or simply decide not to model them at all when faced with other interests and space limitations. Newly built foreign automotive plants rely on trucking and international shipping. Autoparts boxcars and trains are replaced with containers and trucking. Fortunately, moving automobiles over North America by rail is a given, so rail operations around these plants exist, but in a very modern and minimal configuration. Using KIA Georgia as an example, the physical interchange with CSX is a mile over a hill and into a wetland swamp. The only way the non-informed railfan would have any idea that a large automotive assembly plant exists here is some signage, the stored autoracks and the daily visits by the KIA contract switchers and CSX as they trade loads for empties. CSX runs a daily unit autorack train to service the plant each day of production. The train swaps loaded racks for empties and continues on to Atlanta, GA and finally Louisville, KY where the KIAs go for regional distribution and mixing.