Railroad maintenance of way (MW or MofW) operations fascinated me for most of my adult life. Having spent one year with Norfolk Southern as a track laborer on a tie and surface gang in the 1990s, I was exposed to the inner workings of railroad maintenance and construction. My time as a railroader was brief as I figured I was a much better railfan and modeler than railroader. The constant absence from home and family quickly became an issue, and I opted to pursue career options close to home. My short experience left an indelible mark in my modeling that continues to drive my interests years later. Railfan travels focused on all facets of railroad operations, with attention directed to any MofW subjects along with trains and rail operations. I found several rail and transportation trade journals during my college years, giving a technical edge to my research. Along with my observations and documentation of MofW operations during trips trackside, all this information created a useful basis for modeling.

I found that most railfans and modelers lacked any real knowledge of how maintenance processes worked. These operations were not as glamorous and not sought after when compared to trains and train operation. MW usually worked behind the scenes and usually only grabbed attention in the form of ferry moves of rail, ballast or equipment on mainline trains. The equipment, processes and manpower were not obvious and tended to be too complicated in form for the passing railfan. Information could be scarce outside of railroad circles with accurate modeling of modern railroad maintenance quite rare, if nonexistent. The rise of the Internet removed some of these barriers as like minded individuals networked, and information was more easily gathered and communicated. The maturation of 3D printing in the mid 2000 allowed detailed models in very small runs, or details necessary to accurately kitbash MofW subjects..

My short railroad career instilled a desire to incorporate Maintenance of Way operations in my own modeling. Limitations mentioned already did not make fulfilling my goal of accurately modeling any sizable MofW subjects easy. Any MofW modeling subject mimicking accurate prototypes would require hours of scratch building preceded by extensive searches for detailed information. A useful prototype MW operation had to be matched with the available models, or built through kitbashing including may custom built parts. Provided suitable models could be created, the question still remained of how the models could be successfully integrated into a prototypical layout operation. Building a sophisticated model just to have it take up space and collect dust is likely why many modelers find little interest in these subjects in the first place.

OVERVIEW OF BALLAST TRAIN OPERATIONS

After weighing the time/cost versus operational value of a potential MofW subject, I settled on a basic and relatively easy modern subject. It is part train and part equipment, and can be dynamic when included in layout operations. I am referring to ballast trains and surfacing operations. Ballast trains are a key part of roadbed surfacing focused on maintaining the roadbed structure, support and drainage. Railroads refer to the whole process as Surfacing. Surfacing is railroad parlance for the application of rock ballast to the track structure to maintain support of rail and ties while providing critical support and drainage for the track structure. It involves not only application of ballast, but the tamping and profiling by specific equipment necessary to maintain a smooth track profile. Maintaining track roadbed adds to train speed and ride quality, which in turn extends crosstie and rail lifespan. Track sections are typically re-surfaced every 3-5 years on busy mainlines, and less frequently on less traveled sections. Surfacing usually takes place during tie renewal programs usually during tie renewal. In interim years ballast can be added with spot surfacing at trouble points to maintain a smooth and level cross plane and tangent. It is typically one of the more obvious processes, due to the company ballast cars and/or trains that collect around the track section to be surfaced. These can be observed dumping new ballast ahead and during track repair or renewal. A small litany of purpose built machines do the actual tamping and profiling following ballast dumping to complete the process.

Ballast trains typically load the ballast at rock quarrying operations, transport it to the worksite area to be re-surfaced and dump it in a controlled fashion at the site. Ballast unloading can be as rudimentary as manually dumping ballast from a surplus older open top hopper cars one at a time, or in the case of modern practice, automatically spread ballast using GPS location with purpose built automated unit trains. These purpose builrt cars or trains are open hopper cars fitted with specialized doors designed to place ballast strategically and with minimal human intervention using Global Positioning (GPS).. Trains developed over the last two decades range from manual push button activated doors to self-dumping, semi-autonomous GPS-equipped trainsets run remotely by railroad or contractor personnel. Since I model modern era, I wanted to capture the modern automated trains and operations I regularly observed on CSX and NS in the Deep South.

The idea of modern ballasted track structure took hold in the 1960s when heavier trains needed robust track structure with adequate drainage to run at speed. Several railroads found that older post war coal or surplus aggregate cars could be used to haul ballast in company service. In most cases, a local switcher crew would move the cars and roadway personnel would deposit the ballast one chute at the time, manually opening bottom doors. A ralroad crosstie was usually wedged into the leading truck of the first and last car, acting as a rudimentary plow to keep rock from piling over the rails no matter which direction the ballast train worked. Once the manual doors on the cars were knocked open, there was little control of how much ballast spilled. The ballast was then hand tamped by long steel tamping bars manually by the section crews. Hydraulics paved the way for specialized machines to tamp and dress the ballast, increasing speed and reducing manpower. In the 1970s, Morrison-Knudsen patented the first modern manual ballast door designed specifically for dropping ballast in a controlled manner to specific places in the track structure cross-section. Personnel used a tamping bars and mechanical actuator on purpose designed doors to open, direct and close the doors as needed. Ballast could be dropped on the gauge side between the rails or on either shoulder, depending on the way the door was actuated. Later these doors were automated using secondary air lines charged by the locomotive train line. By the early 2000s, these trains had a combination of air and hydraulic mechanisms that could be controlled remotely. Maintenance contractor HERZOG CONTRACTING fielded its own trains after years of building semi-automatic “walk beside” dumping systems for various Class One railroads. The addition of Global Positioning (GPS) transponders allowed a single worker to hi-rail the line to be ballasted and program coordinates for starting and stopping ballast application using solar panels to charge the electrical control and wireless communication system. There was complete control of rock distribution, as well as the ability to autonomously skip road crossings and other track structure obstacles such as switches and bridges. The train could travel at a continuous prescribed speed and the cars would automatically dump ballast based on the pre-programmed computer routine with no need for ground personnel. My knowledge base is heavy in CSX operations, since I live near one of their mainlines. Most Class One and Regional railroads employ similar cars and techniques. Since I have lived many years near the same CSX mainline on the Georgia-Alabama line, I was fortunate to record changes over several decades and is my focus here.

See the video below for a purpose-built Herzog Contracting GPS automatic ballast train dumping on the CSX AWP-WofA Subdivision in 2023. The viewer can actually hear the ballast stop dumping to skip over the switch and road crossing (center and right). The train had stopped so the Herzog supervisor could wirelessly set up the ballast train to dump based on exact coordinates. The train begins moving and accelerates to the dumping speed in the video.

As a prototype freelance modeler in HO Scale with a serious emphasis on operations, the idea of adding a modern dynamic ballast train concept was a priority. By this time in the mid 2000s, manufacturers such as Walthers, Athearn and Atlas were offering various ballast hopper models. The Walthers model had the M-K and later HERZOG designed ballast doors (referred to as gates) typical of modern CSX or HERZOG prototypes, and Atlas and Athearn offered longitudinal cars with Hartz type doors I typically saw on NS (ex Southern) ballast trains. Athearn even offered the correct Thrall coal gondolas in HERZOG colors, but the ballast doors had to be kitbashed or an aftermarket kit purchased to realize an accurate model.

After comparing available prototype information against model availability, I realized the easiest attainable train would be based on the Athearn or Walthers models or some type of similar rebuild. Being a prototype freelance modeler, I decided to use the prototypes I saw on CSX near home to create an operational freelanced ballast train for my Georgia Road in HO scale.

A SUBJECT FOR MODELING

A conversation with fellow modeler Anthony Lorch during this time would prove a fateful moment in my concept design. We shared similar interests, and Anthony was not only an accomplished prototype freelance modeler but enjoyed modeling unique subjects such as my ballast train idea. His own extensive background in railroad operations fueled his modeling, and we both found a mutual interest in the HERZOG contract ballast trains which appeared on all the Class One railroads in the last ten or so years. At first, we set out to document and create a prototypical trainset similar to the HERZOG trains seen on CSX and UP. I was able to walkabout theses trains and shoot dozens of detail shots. I used these to create the base artwork for decals. As time went on, Anthony became more fascinated with the idea of converting prototype HERZOG trains into the prototype freelance world. He remembered I was designing a railroad contractor concept namesake called Stephens Railcar Services (SRCS), which would emulate prototype MW contractor subjects with a freelance twist. SRCS was inspired by Morrison-Knudsen/Boise Locomotive/MPI which maintained shops to repair locomotives and rolling stock and rebuild locomotives and railcars. SRCS ran its own locomotive and railcar shops (RAILCAR DIVISION) and leased locomotives and railcars (LEASING DIVISION). Third, and most importantly to Anthony, SRCS operated a railroad construction, derailment response, and track maintenance side (SERVICES DIVISION). The SERVICES DIVISION had its own ballast trains for hire.

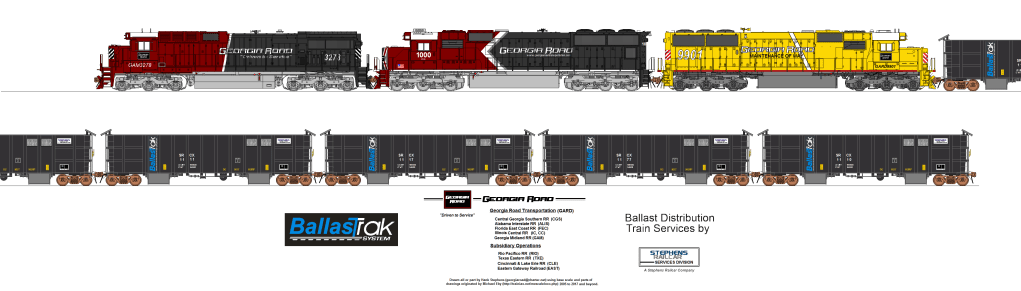

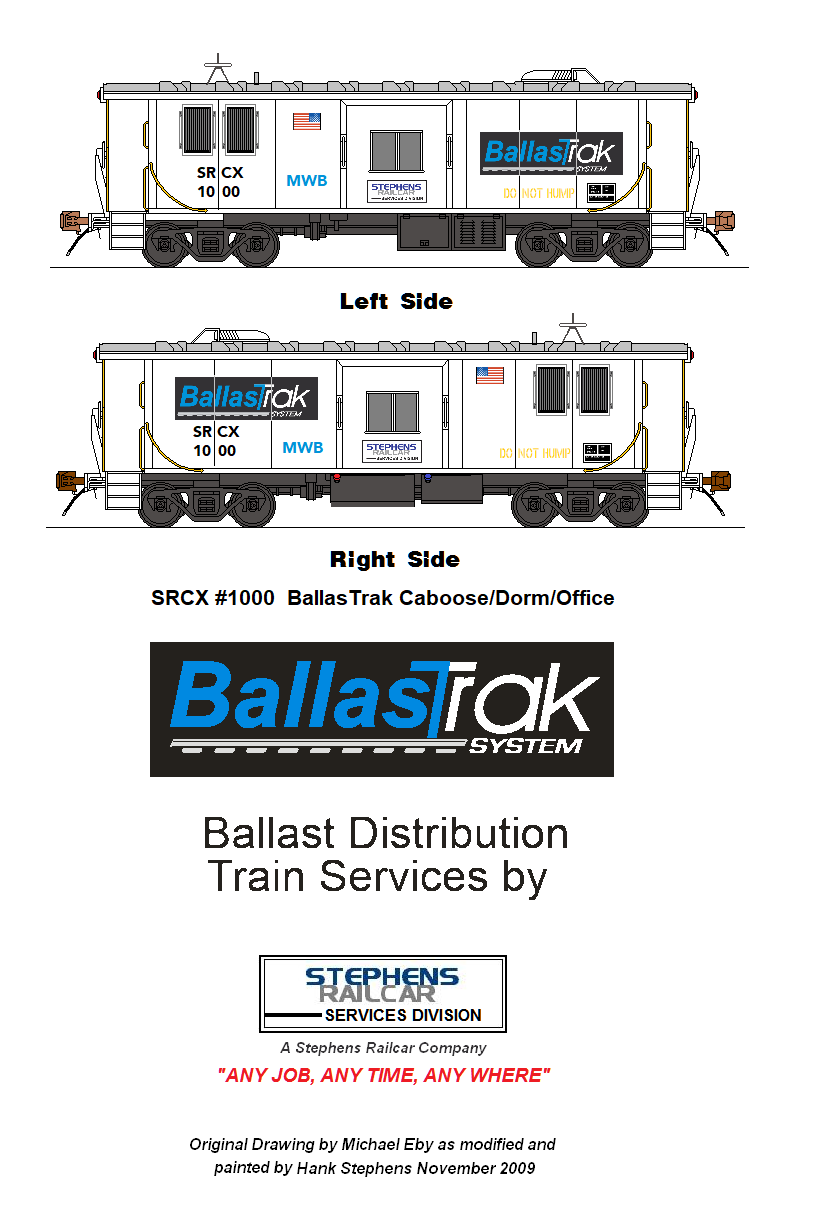

As Anthony and I mulled over various concept details needed to create decal artwork for the HERZOG ballast train decals, he asked if we could change direction and create the train in the prototype freelance world. At first, I did not think much of his request. We brainstormed many prototype and freelance subjects, with most rarely maturing past a few conversations. On our next round of discussions, he mentioned my freelance SRCS concept and asked it a ballast train would be one of the services offered by Stephens Railcar. Armed with his suggestion and encouragement, I set about altered my sketches and created the Stephens Railcar–Services Division unit train. I even branded it as the “BallasTrak” unit ballast train seen below. The color and logos were changed to suit, but the design and decal artwork followed the prototype HERZOG train that started this project. The idea of the “BallasTrak” branding of my freelanced train consisted of a proprietary ballast application system that employed industry standard equipment with custom logistics and tracking software in conjunction with the physical train deploying new ballast. These “BallasTrak” trains were in the form of from basic manual dump system trains or fully automated GPS equipped trains similar to the HERZOG prototype I detailed originally. Below are the concept drawings used to create decal artwork and concept the actual models.

I went so far as to draw a mockup of a typical Georgia Road BallasTrak train, pictured below. As with the likes of KCS recently, and CSXT and CR in decades past, Georgia Road created a pool of older locomotives to work MofW trains, including a specific Maintenance of Way paint scheme to guarantee the units stayed in ballast service.

MODELING THE BALLAST TRAIN

Modeling the BallasTrak car in HO scale is an intermediate project with a working knowledge of painting and decaling. It required the desired number of Athearn Ready to Run Thrall Bathtub gondolas and a list of details created and sold by MACRail, including proper add-on on ballast doors, interior slope sheets and solar panels where applicable. A bit of scrap styrene square stock represented the box with the push button controls on the manual push button sets. Decal artwork was completed and submitted to Matt Welke of Circus City Decals for printing test strips going to Anthony for mock-up and final approval. These are now readily available through Circus City decals linked here–

Circus City Decals https://circusdecals.ecwid.com/

Anthony wanted to model a manual push button train from the early 2000s. I, on the other hand, wanted the more modern fully automated GPS train to match my modern era. Fortunately, the difference was in the addition of solar panels and extra decals to an otherwise standard concept as used by the prototype. To test the design, Anthony created one car each for the manual push button and the newer GPS fully automated configuration. The side by side comparison of finished cars can be seen above. The idea of the dorm/office converted caboose suggested by Anthony for his version of the BallasTrak was also something I wanted on my version. That will be the subject of an addition to this article at a later time.

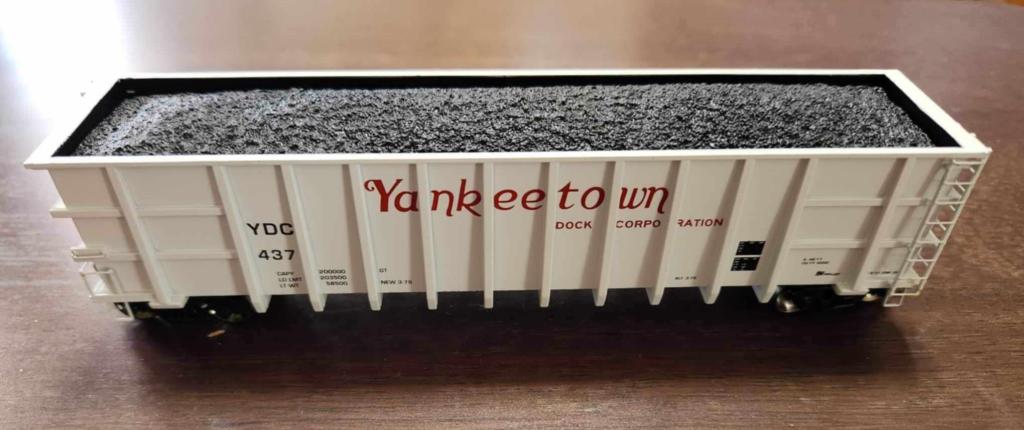

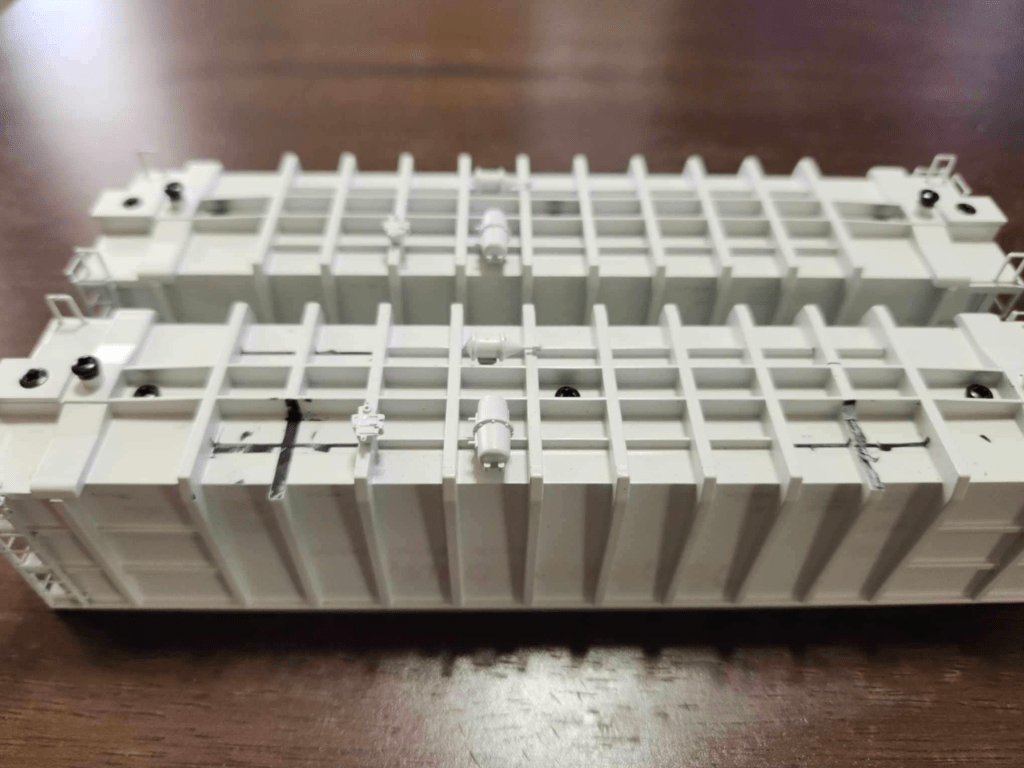

After acquiring the correct cars, The first step is to prepare the model for conversion. Anthony opted for the Yankeetown Dock car as the lettering could be removed and the base white would act as a good primer for the black overcoat. Using repeated passes of applying Micro-Sol and paper towel cut to fit the lettering to be removed, he used Q-tips to remove the lettering while preserving the base white color. See Picture 1 and Picture 2 above.

In my case, I will have to strip my cars in 90-97 percent rubbing alcohol in a sealed container as I have a set painted in ATSF colors with yellow rotary ends.. I will have to separate the ladders and grab irons and re-assemble since the alcohol usually breaks the bond of any details glued to the painted car. Once I complete the build, I will also have to add the step of priming my cars before the black overcoat. The Ready to Roll paint used by Athearn strips both quickly and cleanly. I will not get into much detail about the painting process as many different ways are available. I typically use Tamyra spray cans or an airbrush on my rolling stock builds.

The next step is to remove the second rib from each end of the car to allow the installation of the ballast doors made by MAC Rail MAC Rail Products . https://macrailproducts.com/

For those who want to install doors without damaging the car, MAC Rail also sells a ballast door version with a slot that fits around the rib. Here is the link and the address: All Products https://macrailproducts.com/shop/ols/products/ballast-car-doors-4-pack-herzog-version-number-1-long-mac-821-bll-car-drs-4 .

To be prototypically and visually correct however, I recommend removing the ribs and using the full body ballast doors. glue the doors with a medium thick CA glue. Remember, a little glue goes a long way on smooth joining surfaces. Allow about 12 hours for the glue to cure fully before painting.

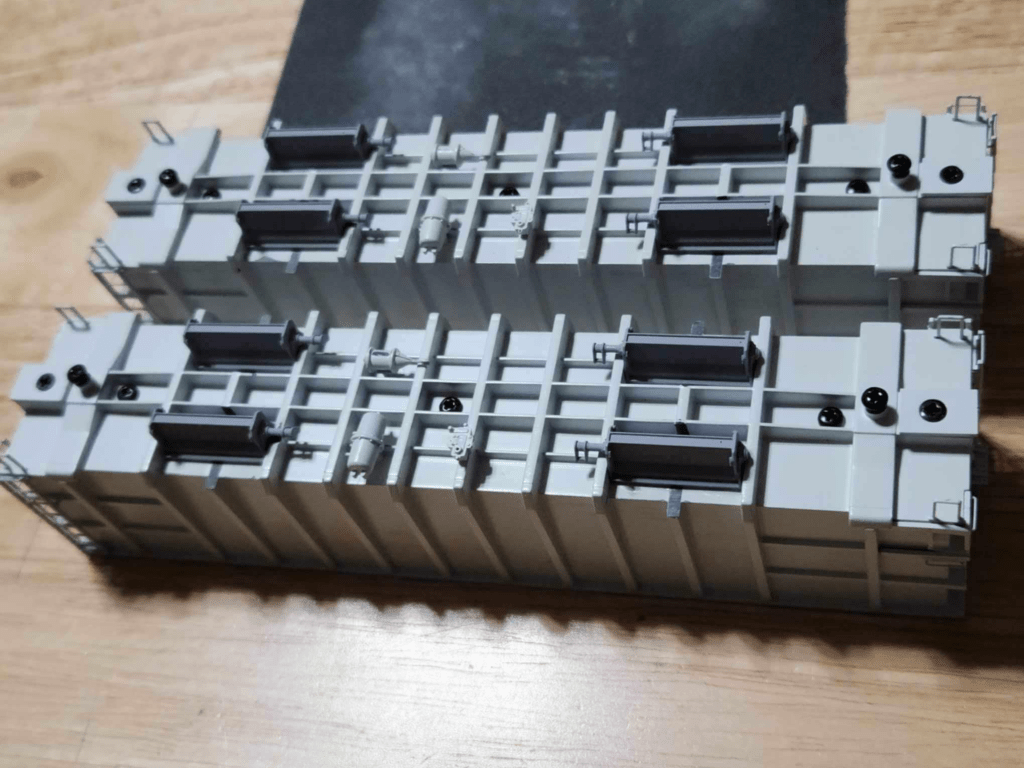

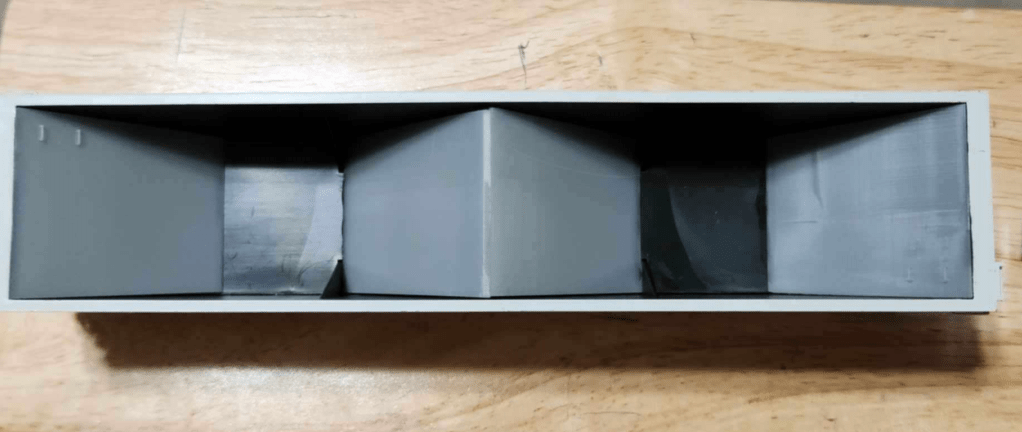

After the glued doors are fully cured, the slope sheets inside the car can be added. The original cars were designed for rotary dump service, so as built the cars did not require slope sheets to gravity feed the contents, and it could be flipped and emptied in less than a minute. HERZOG added the proper slope sheets to the interior to facilitate smooth unloading of the car and to reduce the carrying capacity to maintain the designed maximum weight of the car. Once again, MAC Rail has the correct slope sheets available for purchase to make this step easy. These can also be cut out of styrene with a NWSL duplicator cutting board and glued in place with MEK for those seeking a more cost effective approach. In this case the MAC Rail slope sheets were used to speed up the build. Refer to Picture 5.

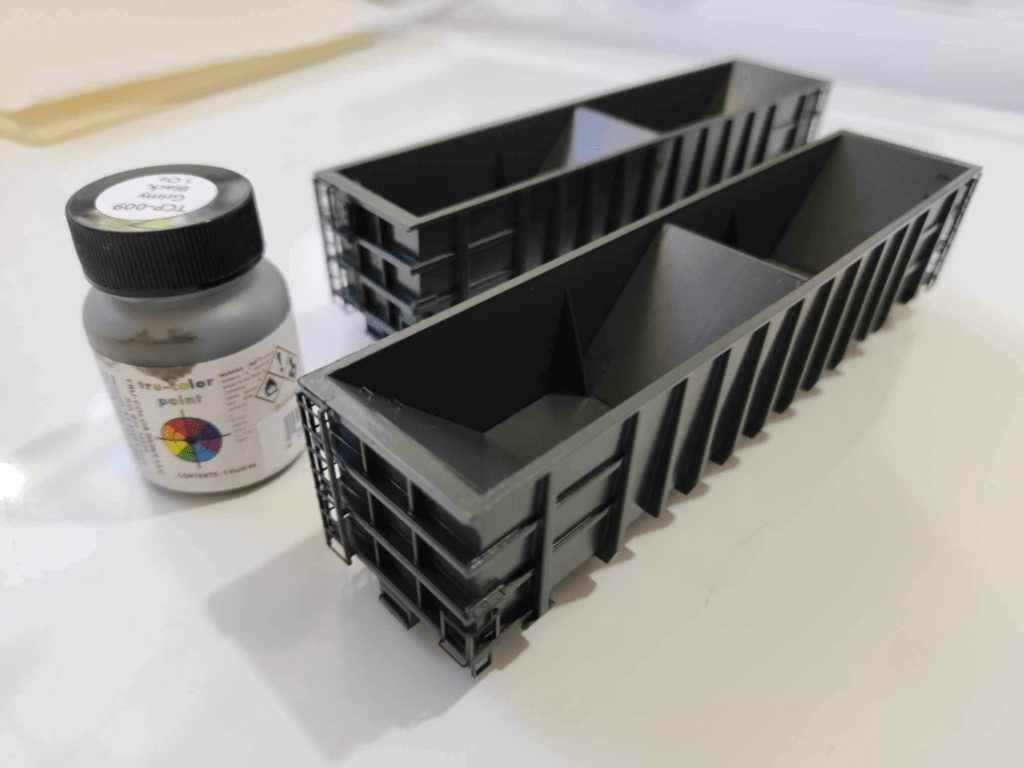

After full curing of the glue, the model is cleaned and airbrushed. Anthony used True Color Weathered Black. With so many options, this article assumes the reader has average painting skills. Once the paint is also fully cured (typically when you no longer smell the paint or thinner), the car is given a Glosscote to give it a shiny sheen. Once this is dry, decals are next. Failing to use a layer of Glosscote can make the edges of the decal film show once they dry completely. Set the decals using Micro-Set by first wetting the area to be decaled and with several applications of it on the decal set in place to blend it into the model paint. When the decals dry and no bubbles or film edges are present, the car should be given a Dullcote or Semi-Glosscote layer to seal the decals. If done properly, the decals will appear painted with no film edges present. It takes some work and repetition, but the results are well worth the effort as seen in Picture 7. At this point, the final details such as the solar panels and push button box can be added as desired.

BALLAST TRAIN OPERATIONS AND FINAL THOUGHTS

Operationally, both the push button manual unloading car and its newer GPS fully automatic car configuration continue to be relevant to modern railroading from the late 1990s until present. The older car lacks the solar powered batteries to operate doors, using train or locomotive air to actuate the doors. They also require MofW workers on the ground working the cars. These cars replaced the fully manual and repurposed coal and aggregate cars in the 1990s and removes the hard labor of opening the doors by hand with a lining bar. By the 2000s, the manuals were mostly relegated to small jobs and handled in mixed freight moves. The newer GPS solar power cars were not designed for the smaller ballast jobs, intended to address areas where trainloads instead of carloads of ballast were needed. The advantage is these GPS cars be preprogrammed with a dump routine a singled worker hi-railing the section to be ballasted and simply monitoring the train as it worked. Dumping could be pinpointed to a few feet, allowing the train to automatically skip bridges, switches and road crossing as programmed. The train could move continuously at a prescribed track speed with no need for workers on the ground and potential injury from walking around moving equipment.

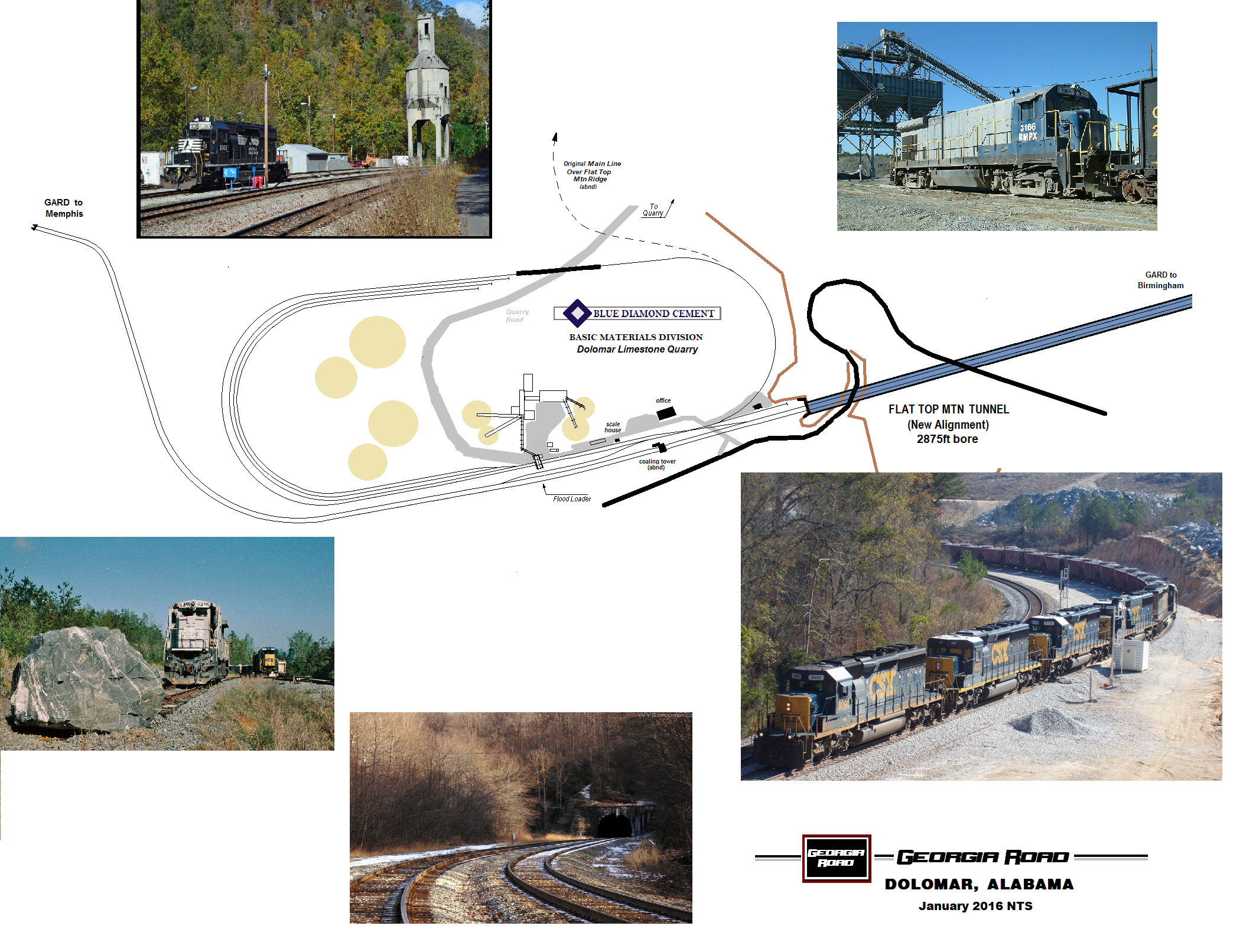

Layout operations could include individual cars of the older cars set out by scheduled freights and placed by local crews. Full trains of these cars could represent a extra move as they are traveling from quarry to the job site and back. Operators could actually simulate the dumping operation using removable loads and track bulletins and warrants. If s quarry operation is modeled, these cars could be loaded in mixes of railroad customer cars or as full unit trains similar to a coal loadout. For example, on the Georgia Road –Alabama Interstate Division in HO Scale, the unit trains not only drop ballast ahead of tie and surface gangs, but regularly loads at a large Blue Diamond quarry at Dolomar, AL on the modeled section. This quarry represents a loading loop and actually sits on top on one of the helix loops. Dolomar has its own customer base, but at certain times of the year sells ballast to Georgia Road and nearby Class One railroads using the BallasTrak GPS trains to deliver. These trains arrive empty and enter the loop where they slow load under a tipple. These moves have to be planned so not to congest operations for other non-railroad customers, requiring some switching by the Blue Diamond quarry switch locomotives (Picture 10).

Picture 10–Georgia Road origination point for loaded BallasTrak trains Dolomar, AL

Picture 11– Anthony Lorch’s Kansas Pacific RR (KP) SD40-2 #4203 and un-pictured partner take time out from local switching duties to drop a single car of ballast for the resident roadmaster in the area. This single car was brought in by the Alpine Local along with its normal local traffic and dumped between switching chores. A spot tamping crew will follow and correct a few soft spots in the roadbed to improve ride quality for the trains on this particularly rough section of track. With ballast now laid, the SDs and their single empty car head back to pick up their train and finish the switching of the day. If truth be known, neither the Alpine Local crew nor the road train waiting a few miles west were pleased over the extra work and delay. The roadmaster was quick to remind all of then that the railroad has to be maintained!