Radio Control Cabs/Fuel Tenders

Radio Control Cabs

The expanded use of Radio Control Switching was not new when Georgia Road visited the idea in the early 2000s. Technological advances in radio control allowed not only for remote control of locomotives, but remote powered switches and yard territory interlock controls to safely protect crews on the ground engaged in remote controlled switching. Georgia Road saw the Radio Control idea as a way to streamline yard operations and some specific terminal road switching. Adding belt pack remote controls to personnel on the ground was only a small part of the system which also required complete configuration of classification and marshalling points to isolate operations from overlapping road train and yard operations.

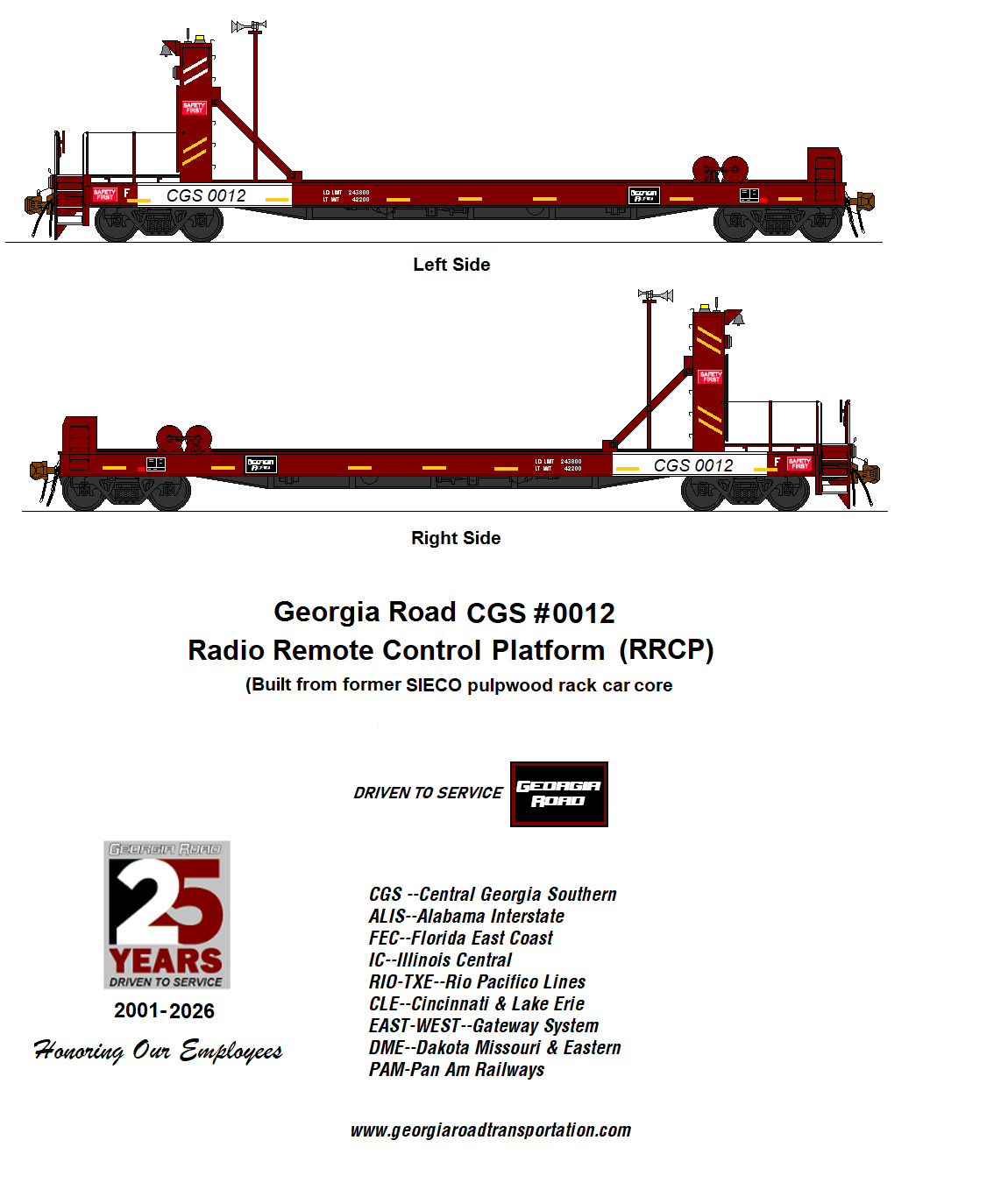

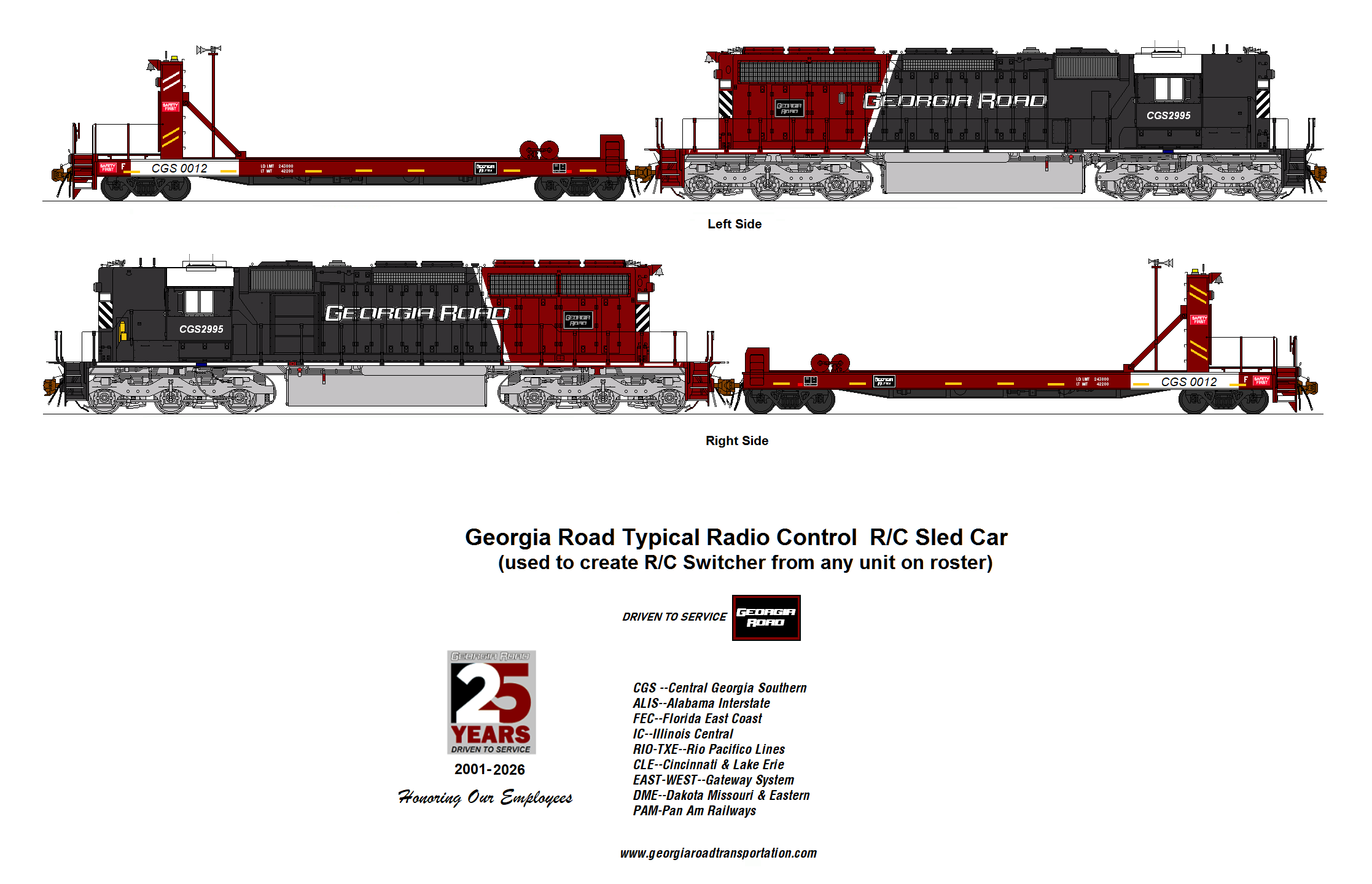

Georgia Road borrowed a page from CSX Transportation by converting surplus bulkhead pulpwood rack cars as Radio Remote Control Platforms or RRCP units. These cars contained all the required Radio Control electronics to allow the RRCP to act as a R/C leader. Any locomotive could be MU ‘ed to these platform cars and be used in R/C switching, without need for any modifications to the locomotive. Georgia Road deviated from the CSX design by outfitting the platforms with full locomotive pilots to ease crew access and reduce climbing. Furthermore, these operations were limited to specific locations configured to protect R/C operations. The platforms were considered a moderate success, with 18 units placed across the system, primarily on Georgia Road’s Central Georgia Southern RR (CGS) and Alabama Interstate RR (ALIS) operations.

In addition to the converted railcar platforms, Georgia Road also created Radio Remote Controlled Locomotives or RRCL units. These were retired road and yard locomotives that had primemovers and fuel tanks removed with radio equipment added to the cab. The RRCL units were also set up as slugs in some cases and were earmarked for terminal and some limited heavy switching. Former GAM retired GE U series units were converted for road service and sandwiched between operational locomotives, giving crews extra tractive effort as a slug and the R/C control when needed to make extensive switching efficient. These worked large customers requiring shuffling of large cuts of cars on various secondary and branches in Georgia. The RRCL idea was also applied to the IC and DME lines, primarily connected to transloading customers across the system.

| Road Number | Model | Total Units | Notes |

| 0001-0019 | Radio Remote Control Platform-RRCP | 18 | 1 |

| 0080-0089 | Radio Remote Control Locomotive–RRCL EMD core | 10 | 2 |

| 0090-0099 | Radio Remote Control Locomotive–RRCL GE core | 10 | 2 |

Note 2–Locomotives have primemovers and fuel tanks removed. Some units set up as slugs for extra tractive effort, Various models used from retired EMD and GE high short hood core locomotives.

FUEL TENDERS

In 2015 Georgia Road began to study the feasibility of adding Fuel Tenders to its long distance interline trains. Georgia Road regularly operated Powder River Coal trains via is DME connection into the Western coal region, cycling them to generators in GA, AL, FL and SC. This long-distance pool was second in distance only to the premium QuickSilver “Eagle Flyer” trains moving to and from the West Coast using Kansas Pacific Railroad (KP) and Chinook Lines (CHNK) connections. With Birmingham, AL being the principal service point for the locomotive in both pools. Some of the cheapest fuel prices in the nation log around Birmingham, mainly due to it being the location of two major pipeline terminals between the Gulf Coast refineries and the Northeast and Midwestern sections of the country. Due to considerable taxes levied by fuel purchased on the West Coast, the idea was presented for the operating range of these fast-turning trains to be extended to allow fueling at home terminals in the Southeast, at significant costs savings.

Around the same time, regional operator Squirrel Valley Railroad Company (SVRC) was experimenting with its own fuel tender sets, mainly aimed at increasing locomotive availability by moving its trains in full cycles across its system with minimal need for enroute refueling. While using fuel tenders was not new, the SVRC created a “plug and pump” system that allowed locomotives to be quickly converted to work with these “smart” tenders with little more than software upgrades, piping, and integrated valves to allow fueling on the road. The novel approach was the fact that the fuel tender carried pumps and control systems and was completely self-contained. The addition of a set of MU pins and minimal piping with paired locomotives made the system modular and expandable in a fleet with minimal costs. The “smart tender” system piqued the interest of Georgia Road technical managers, and SVRC was approached for a licensing deal, which it branded under its Fuel-X-Tender. (TM) name under a subsidiary company called SVRC Handling Systems.

Georgia Road worked with SVRC Handling Systems to modify the system to meet specific Georgia Road operations. The smart tender was upgraded with a “plug and pump” system where the tender could add up to two Fuel-X-Tender equipped units per end. The tender could refuel two units twice with a full load of fuel, or once if four units were “daisy-chained” to a tender. The locomotives required only extra piping and integrated valves with control executed from the tender. Hoses were designed in a plug-vacuum system that allowed them to be disconnected with a special wrench carried on the tender which also allowed couplers to be unlocked for separation of units and/or tenders for re-consisting. The slug used two main air injected transfer pumps, utilizing stored locomotive brake air retained it the auxiliary air tank of the tender. The tender would only fuel when the train was stopped and sensors in the tender reported good operation. An additional design element allowed for purging transfer lines leaving the system empty during movement as a safety precaution in case of accidental breach.

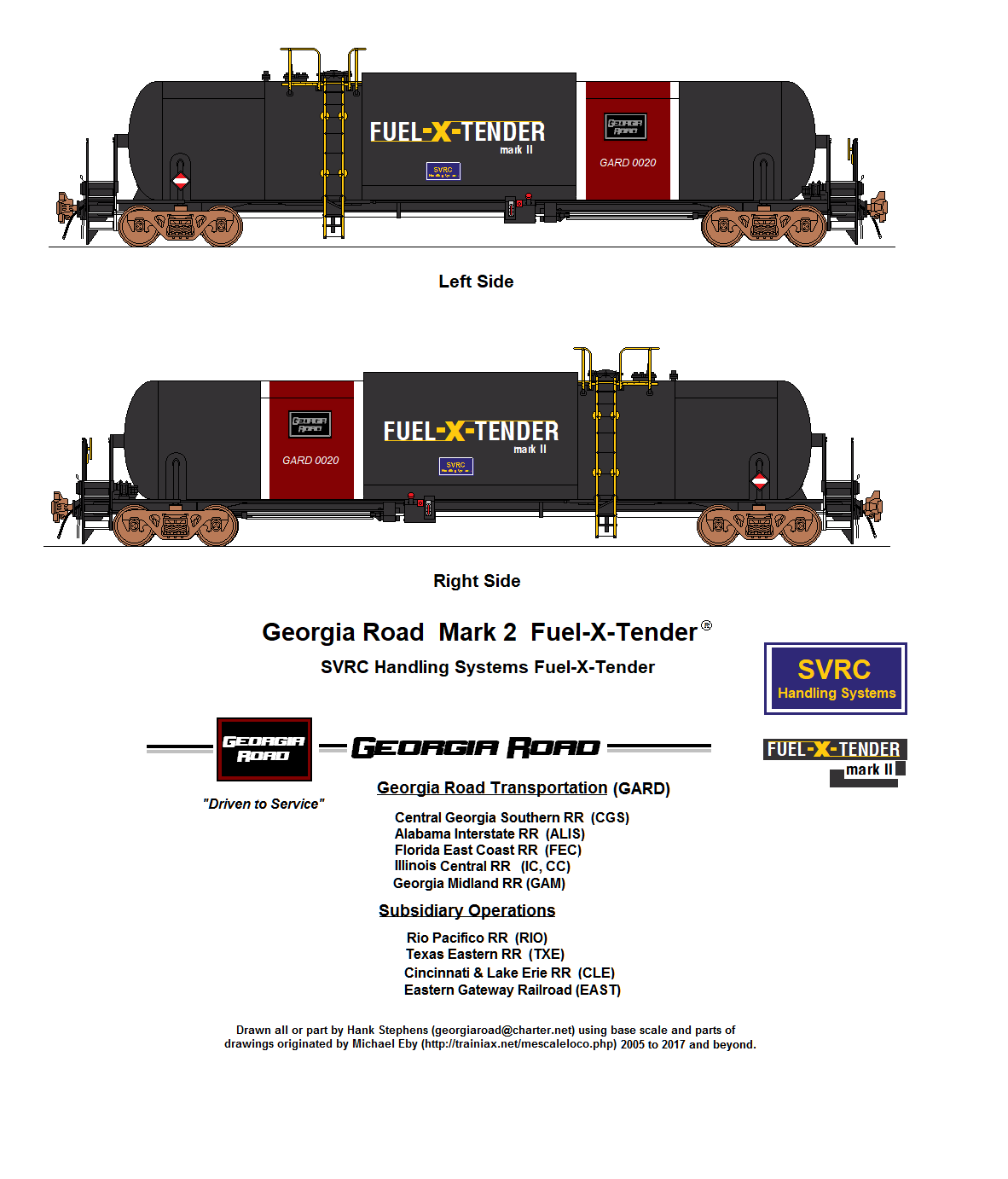

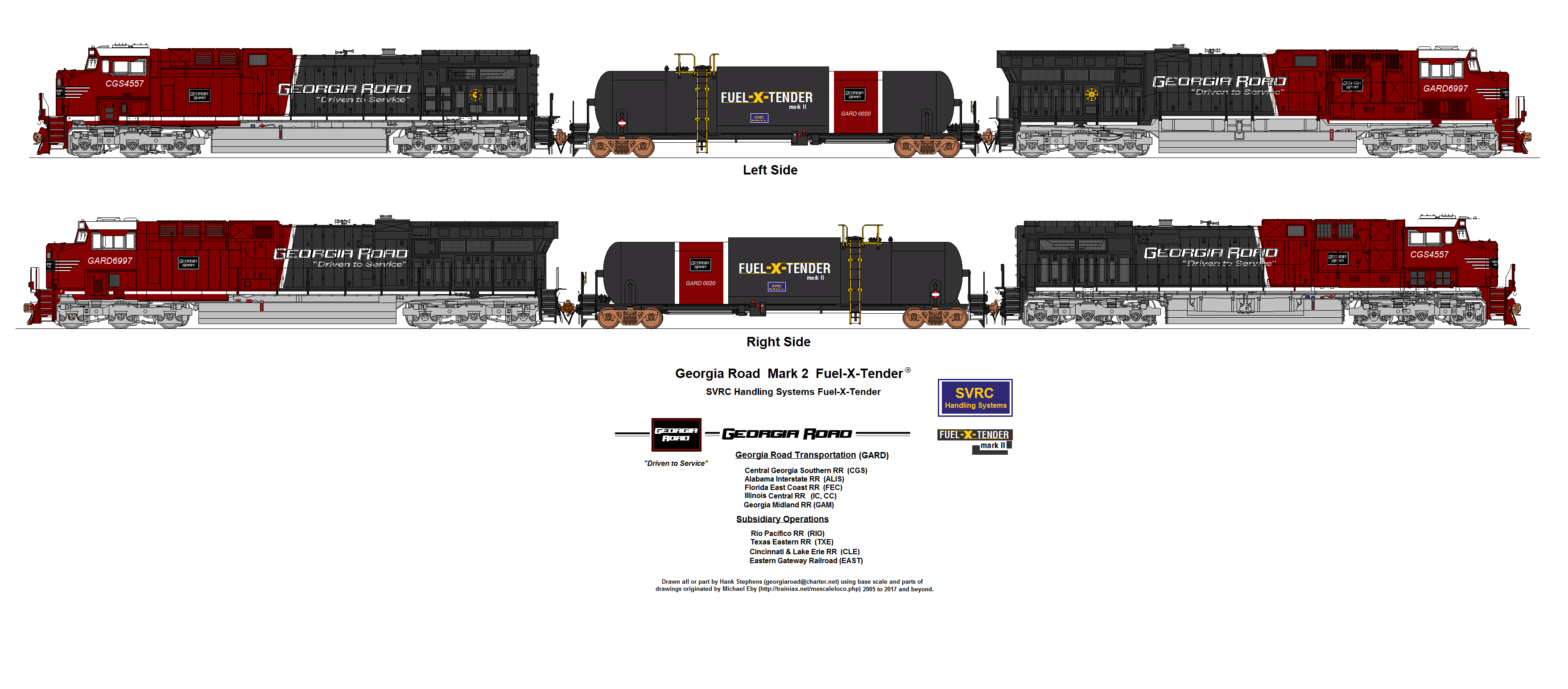

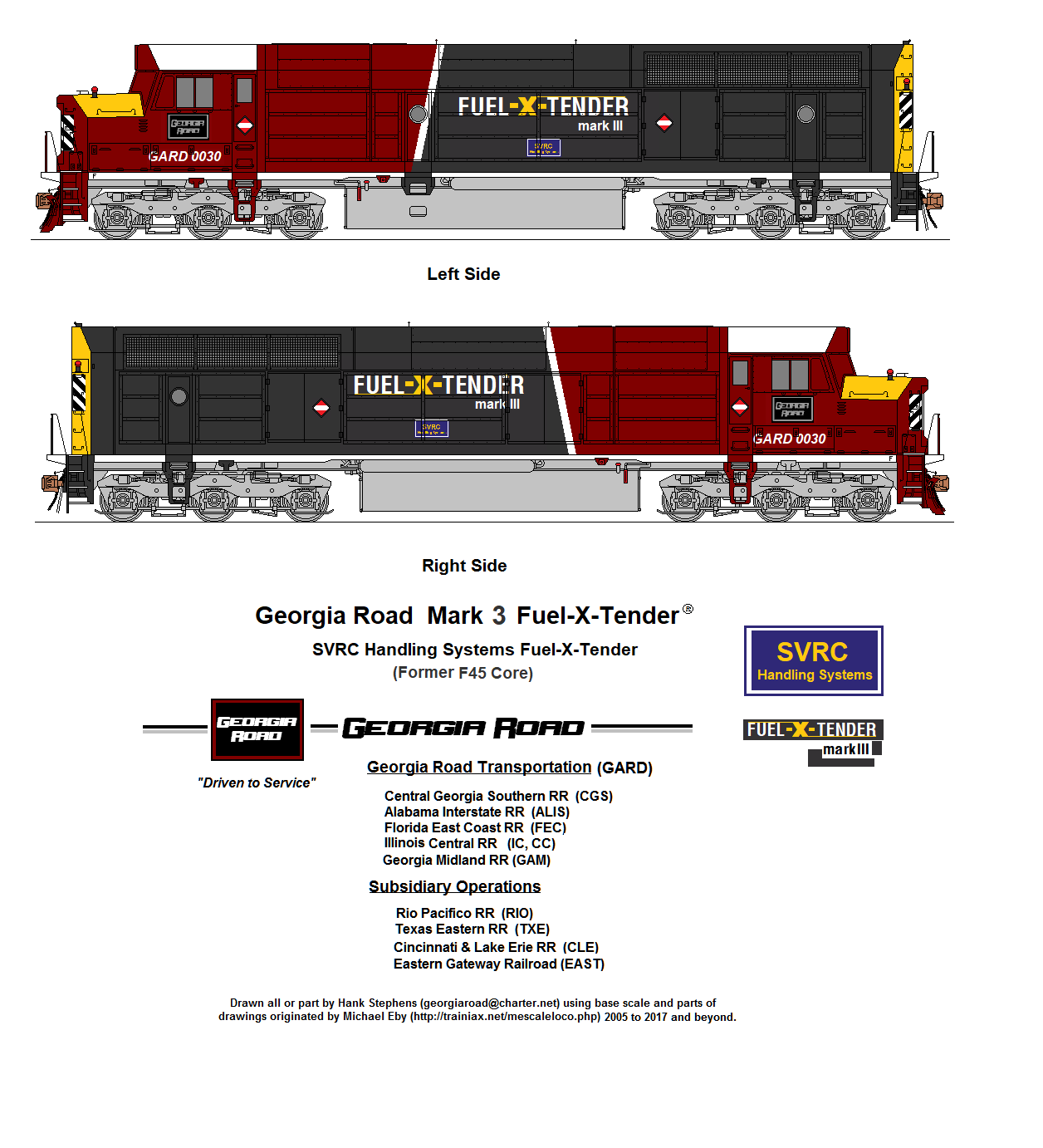

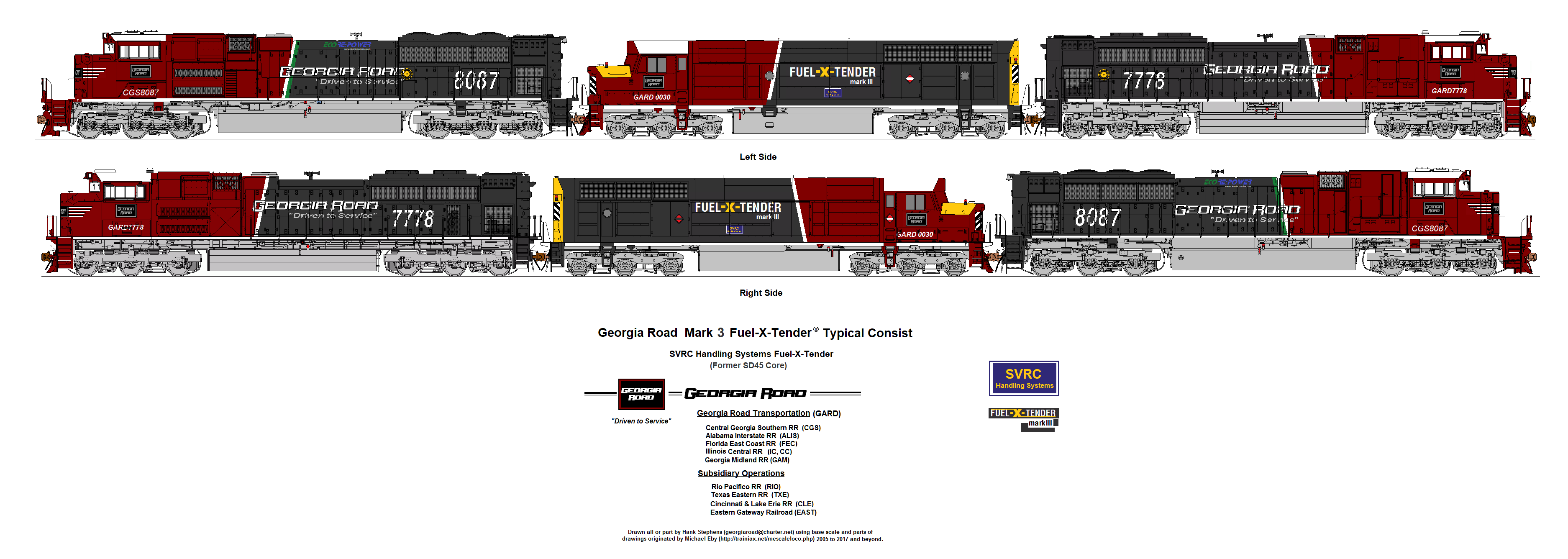

Georgia Road commissioned Stephens Railcar to produce four prototype Fuel-X-Tender units in late 2016. These were highly modified tank cars with custom facility arrangement including locomotive pilots to ease in moving on and off the tender. Known as the Mark 2 version, it mirrored some design elements of the original SVRC design, which were considered Mark 1 versions. After several months of testing, operational feedback suggested the need for more accessibility across the tender-locomotive consist and hardened impact resistance. The Mark 1 and Mark 2 tank cars had not accommodation allowing crew to cross over the consists while the train was in motion and concerns were raised about the integrity of the tender if involved in a derailment. The Mark 3 version saw two more prototypes, created from former F45 cores owned by Stephens Railcar. These fuel tenders had modified noses allowing crews to pass through at speed and were significantly more robust in design using the inherent hardened characteristics of the locomotive core. The F45s had their car bodies sealed, all traction motors, sand and sand provision removed, cabs stripped and converted to the main pump and control room, and fuel cells in place of a primemover. The original fuel tanks were ballasted with concrete to maintain nominal weight regardless of fuel load. These units joined the two Mark Two tank car fuel tenders in Eagle Flyer intermodal trains cycling between the Northwest and Birmingham, AL. These F45s became the preference for West Coast long distance stack trains and Stephens Railcar built six additional units on F45 cores bringing the total to eight Mark 3 fuel tenders in service.

In late 2016 into 2017, Georgia Road received the last of its SD70ACe and SD70M-2 orders from EMD. With the success of the Mark 3 tender configuration, EMD was approached to supply kits for parts-compatible fuel tenders to work with the fleet of SD70ACe and SD70M-2 units. EMD supplied production frames, truck assemblies and OEM parts which were sent to Stephens Railcar for assembly and completion. The first of the Mark 4 Fuel-X-Tenders entered service with the last 10 SD70Ace units delivered by EMD in mid 2017 (Georgia Road had emissions credits for the units, now called SD70AH locomotives). Plans called for a total of 20 Mark 4 tenders to be built, evenly spread between Powder River Coal and Eagle Flyer pools. Additional Georgia Road locomotive classes were modified for use with the fuel tender system in 218-2020, including the new SD70MAX units, rebuilt at Stephens Railcar under their new ECO RE:Power Program. GE Wabtec delivered 50 ES44AC and ES44C4 from the factory with provision for work with Fuel-X-Tender with the intent of outfitting at least fifty percent of locomotives in the Powder River Coal and QuickSilver Intermodal pools, respectively.

Note: Special Thanks to Kev Caldwell and his Squirrel Valley Railroad in N scale for use of the Fuel-X-Tender idea. Please refer to upcoming modeling articles for more information

| Road Number | Model | Total Units | Notes |

| 0020-0023 | MARK 2 Fuel Tender (converted Pressure Tank Car) | 4 | 1 |

| 0030-0033 | Mark3 Fuel Tender (converted F45 locomotive core) | 6 | 2 |

| 0040-0059 | Mark 4 Fuel Tender (OEM construction) | 10 | 3 |

Note 2– First production version fuel tender created from F45 cores by Stephens Railcar, LLC.

Note 3–Final production version Fuel Tender–kits supplied by EMD and assembled and completed by Stephens Railcar. Program still ongoing in 2023.