OVERVIEW

Stephens Railcar Services (SRCS) is a railroad rebuild and repair company with twenty-five years of experience in the railroad support industry. Its two shop complexes at Dadeville, AL and Birmingham, AL can handle any project ranging from derailment repairs to total capital rebuilding. SRCS can handle stripping and painting, structural fabrication, FRA inspections, brake repairs and wheel truing. SRCS maintains a lease fleet of locomotives and railcars under its SRCX Leasing subsidiary. This leasing company provides a cost-effective approach to both acute and chronic locomotive and railcar needs. It also addresses transportation logistics and fleet management requirements. The SRCS Services Division specializes in derailment clean-up, HAZMAT response and general maintenance of way and construction.

Dadeville Railcar Shops and the Dadeville Loop Industrial Railroad

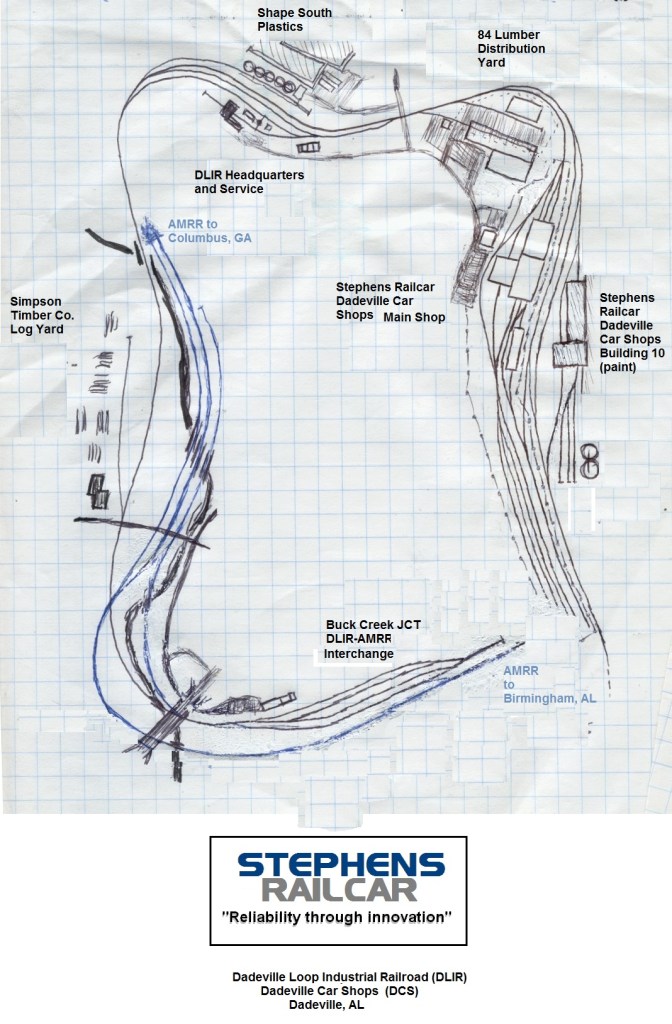

Stephens Railcar’s Locomotive and Railcar Division consists of two heavy repair shops located in Alabama, both served by Class one Georgia Road Transportation. The eighty-four acre facility at Dadeville, AL is known as the Dadeville Car Shops. It is located on the site of the former Central of Georgia original mainline alignment operated by SRCS as the Dadeville Loop Industrial Railroad (DLIR). The railroad is considered a class three carrier and links the Dadeville Car Shops in the Dadeville South Industrial Part to the Georgia Road interchange north of the city at Buck Creek, AL. This original alignment through the city of Dadeville was known historically as the Dadeville Loop Industrial track. It came into being when the original owner Central of Georgia Railroad built a new alignment to reduce gradient and curvature west of town. For many years, CofGA and later Southern Railway used the Dadeville Loop as a long passing siding to route mainline trains around locals, which took the Dadeville Loop alignment. With the advent of the Norfolk Southern in the late 1980s, the Dadeville Loop was severed on the south side and became a long industrial track serving industry in downtown Dadeville and the industrial part when the line was embargoed. Trains working the Loop had to access the line from Buck Creek Junction on the north side.

In 1990, Stephens Railcar Services bought the Dadeville Loop trackage from Norfolk Southern with the intent of building a larger modern railcar repair facility to replace its Montgomery, AL operation located at the deteriorating Western Railway of Alabama (WofA) shops. This completely modern facility would specialize in all facets of railroad car repairs, from program fleet maintenance up to re-capitalization rebuilding. It included a separate paint barn with a state-of-the-art sand blasting and paint system. The facility also held storage capacity for over 200 railcar projects, something the space limited Montgomery Car Shops lacked. The main shop floor can house up to 20 cars or locomotives at a time in an advancing production station form. This new shop complex would replace the original Montgomery location, which was closed once the Dadeville Car Shops ramped up to full operation.

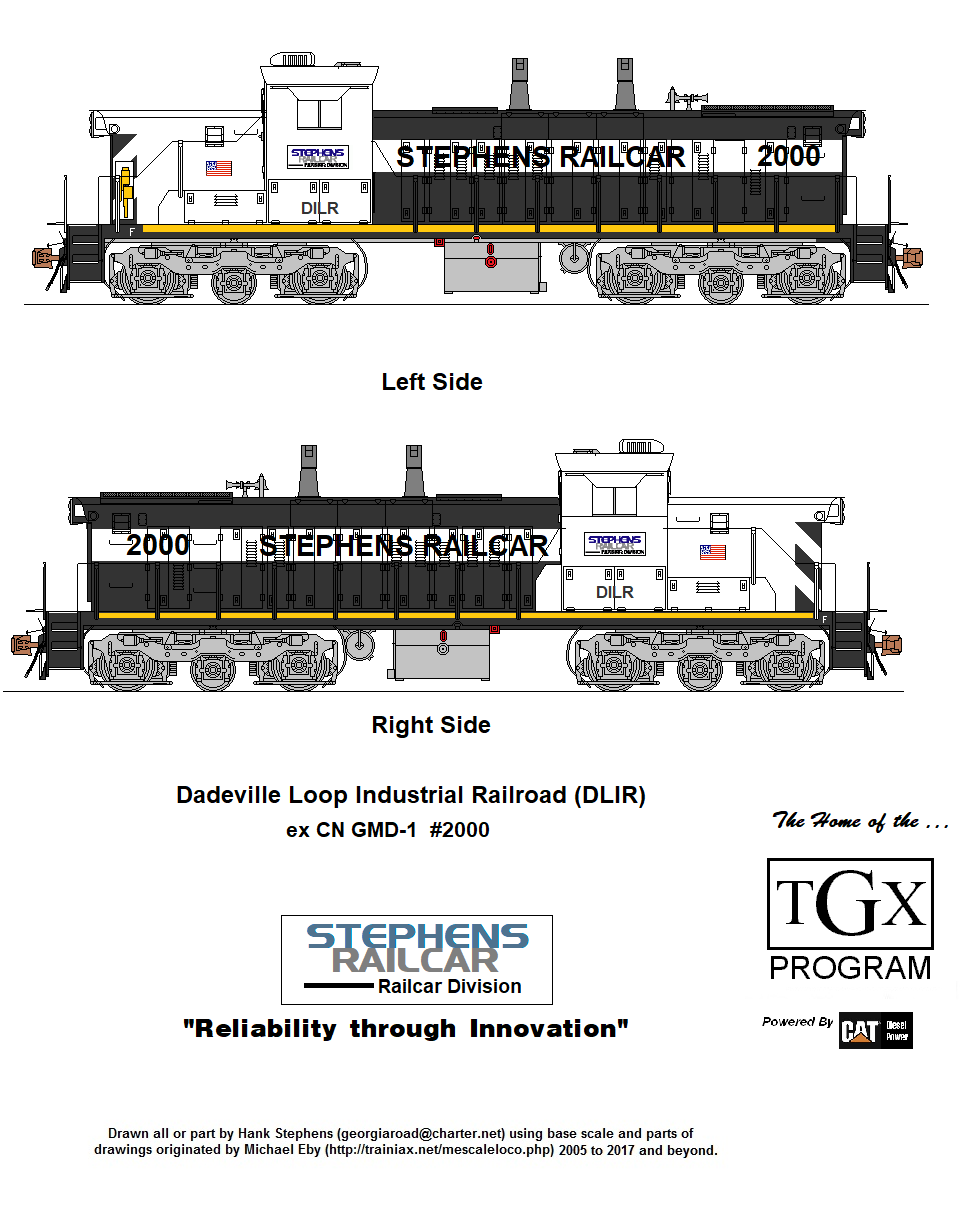

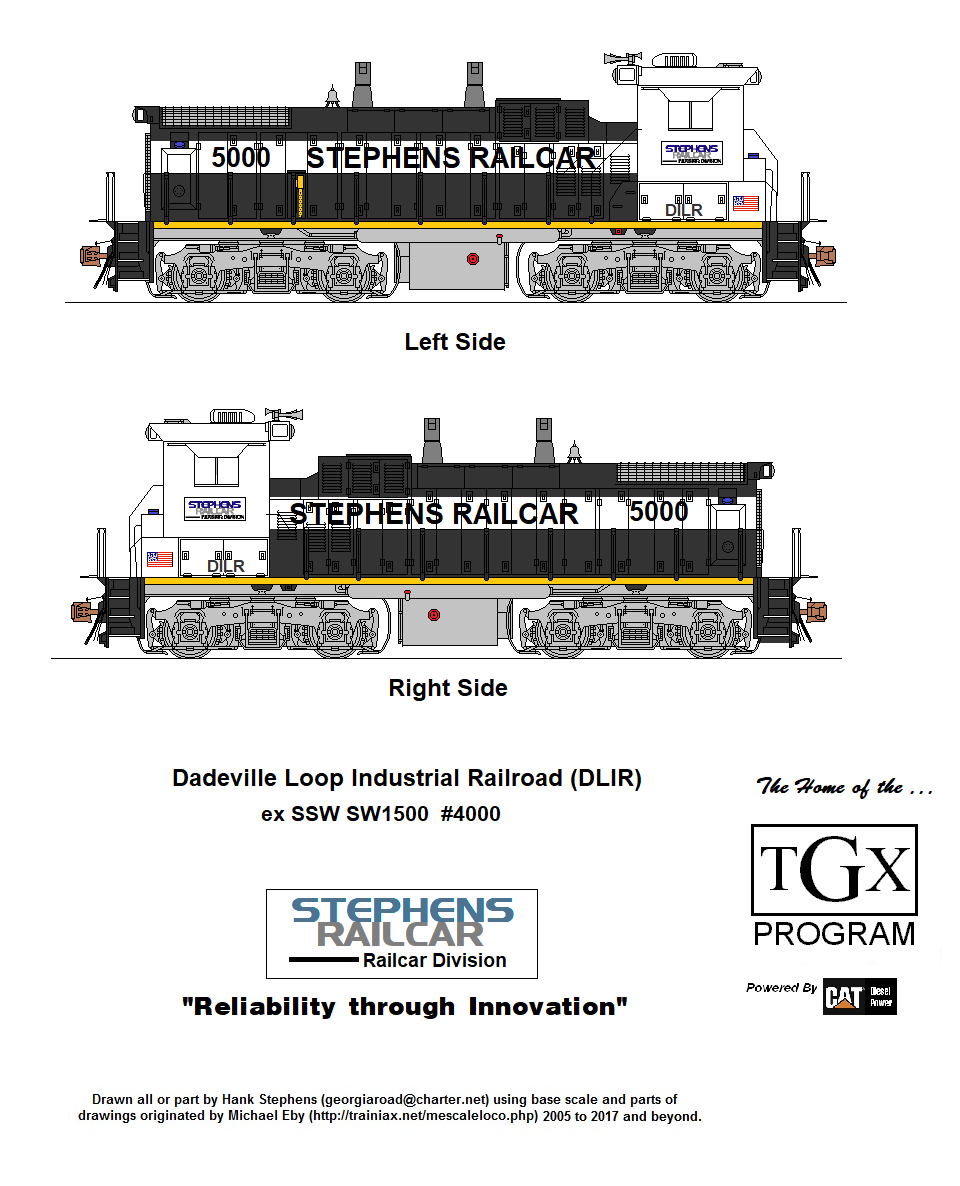

To service the new shop complex, Stephens Railcar Services incorporated the Dadeville Loop Industrial Railroad (DLIR), a fully owned Class Three terminal common carrier railroad which would not only service the shop, but all the independent customers on the eleven-mile line. The DLIR was headquartered in the fully restored CofGA Dadeville depot, with a small service and inspection building built next to the depot in the yard tracks. A small fleet of switcher type locomotives was acquired to work the shop and unrelated customers on the line including a building supply distributor, Shape South Plastics extrusion plant and the Dadeville Log Yard near the DLIR interchange at Buck Creek Junction.

John Tyler Locomotive Shop and the Services Division

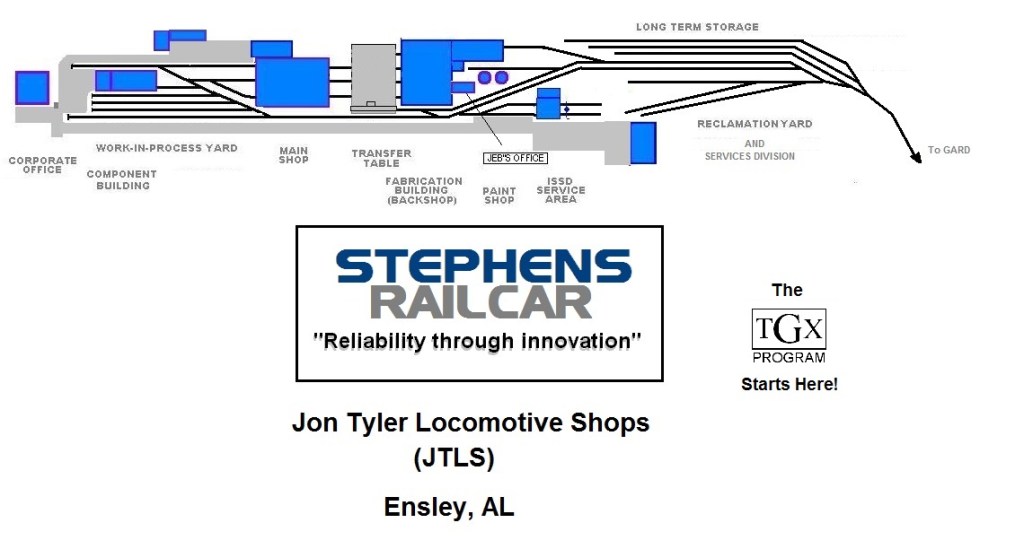

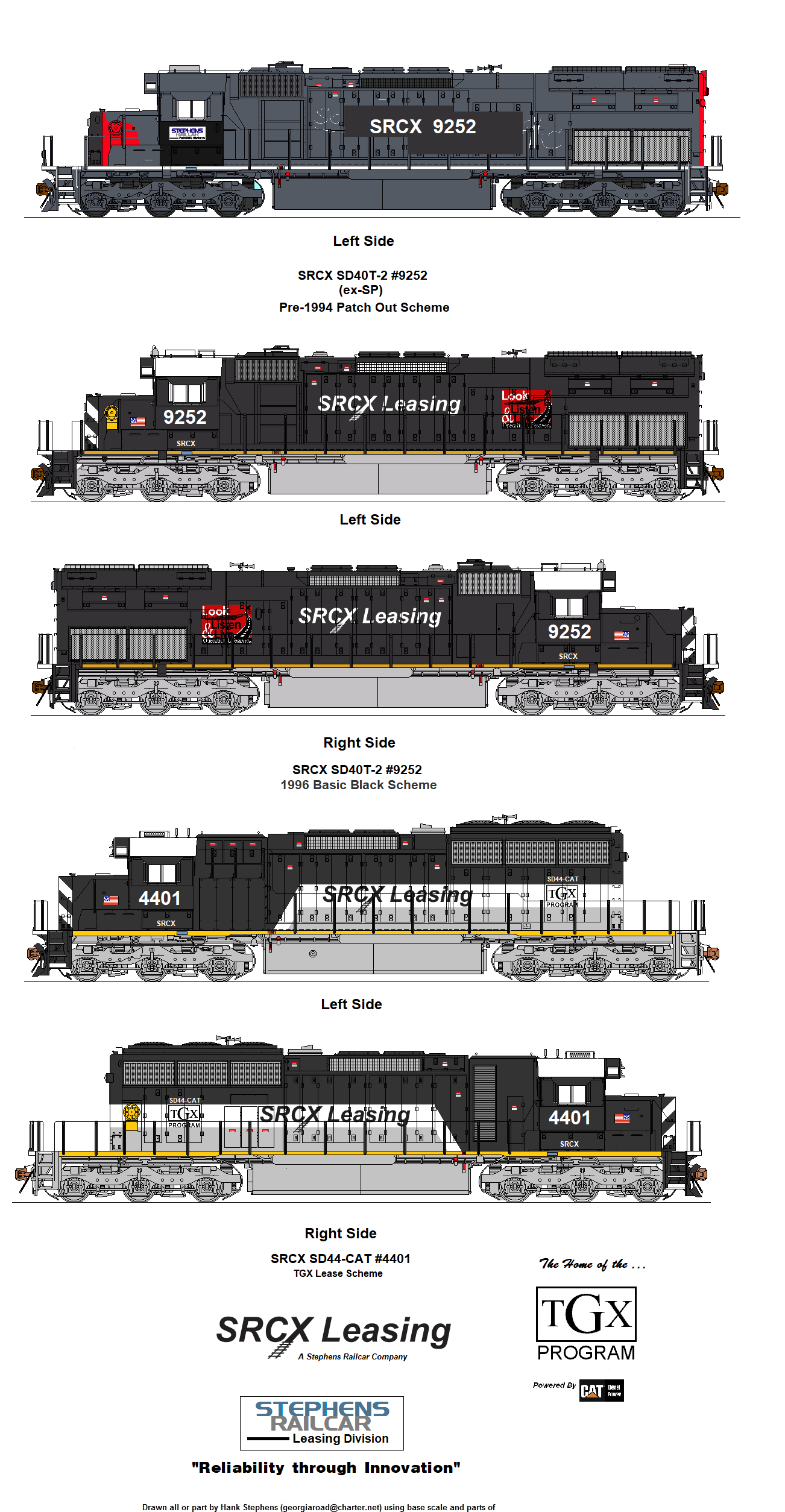

Locomotive repair and rebuilding became an increasing part of the Stephens Railcar Services portfolia during the late 1990s into the early 2000s. The introduction of the proprietary TGX Program of OEM rebuilt locomotives began in the early days of the the Dadeville Car Shops operation as a side note in 1994. By 2000, the TGX Program saw a full launch and space needed to remanufacture these locomotives became a premium as it threatened the railcar repair side, a long-time staple of the overall business. Space needed for railcar production was increasingly crowded by locomotives on the TGX line, both inside the shops and in the work in process and storage yards around the plant. As a result, Stephens Railcar Services opened a second shop in Ensley, AL specifically aimed at locomotive repair and rebuilding. It would also be the home base of the growing TGX Program of rebuilder new OEM locomotives.

A fifty-five acre site was chosen at the old Ensley Steel Mill site in the Birmingham, AL suburb of Ensley. Ensley was built as a steel mill town, surroundings the old Tennessee Iron and Coal (TCI) steel mill located there in the late 1800s. The mill was the center of the town for over a hundred years until it was closed in the late 1970s and finally razed in the 1980s as an EPA superfund site. Part of the superfund clean-up was the sequestration or removal of a century of hazardous materials. The land was then repurposed as an industrial part consisting of a large Georgia Road QuickSilver intermodal ramp which claimed much of the old mill site, and the new Stephens Railcar John Tyler Locomotive Shops (JTLS). The thirty-five acre facility could completely strip a locomotive, return it to OEM standards or completely remanufacture it under the TGX Program, and support all needed OEM functions such as parts and service for TGX Program locomotives. The JTLS could double as an overflow point for the Dadeville Car Shops if locomotive business was slow, so railcar rebuilding could keep the plant at full production.

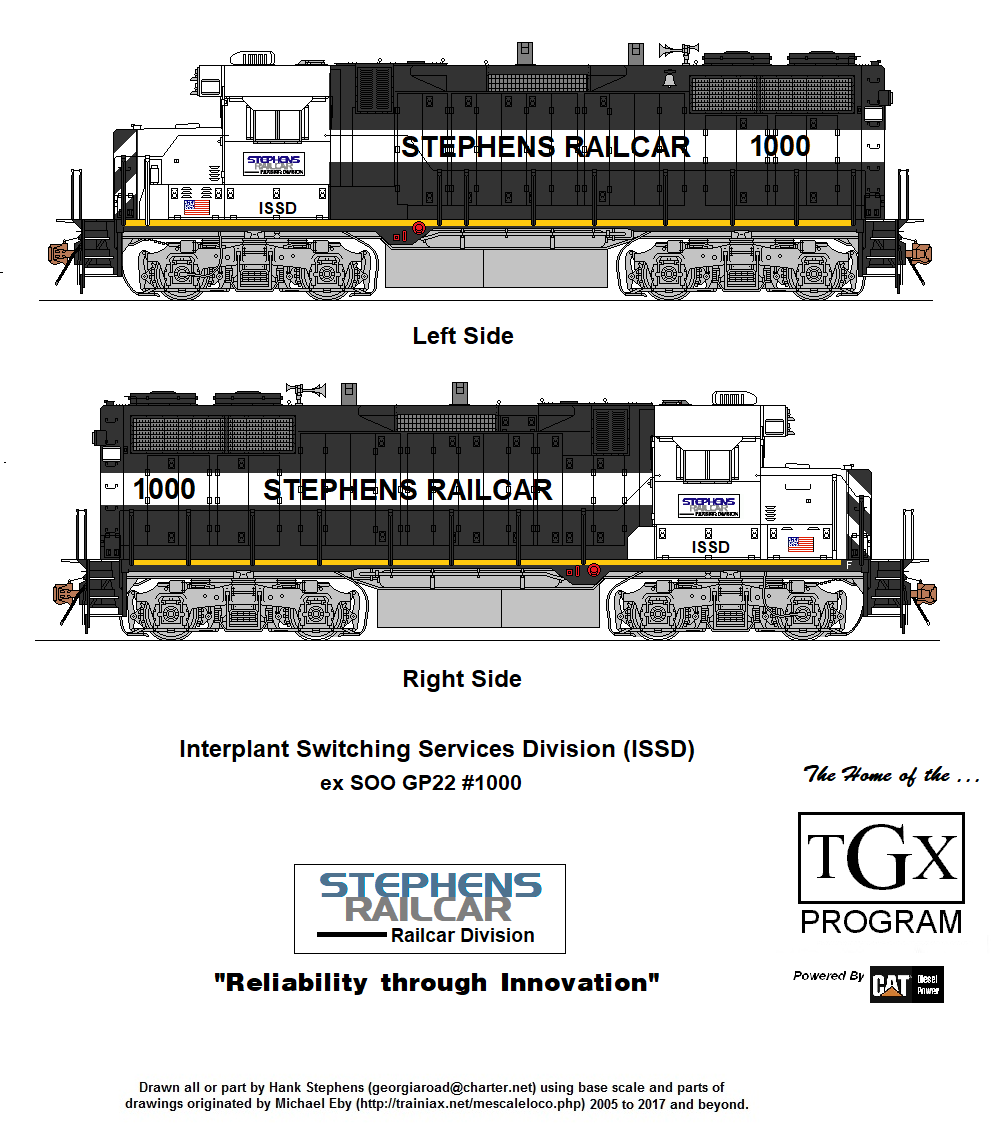

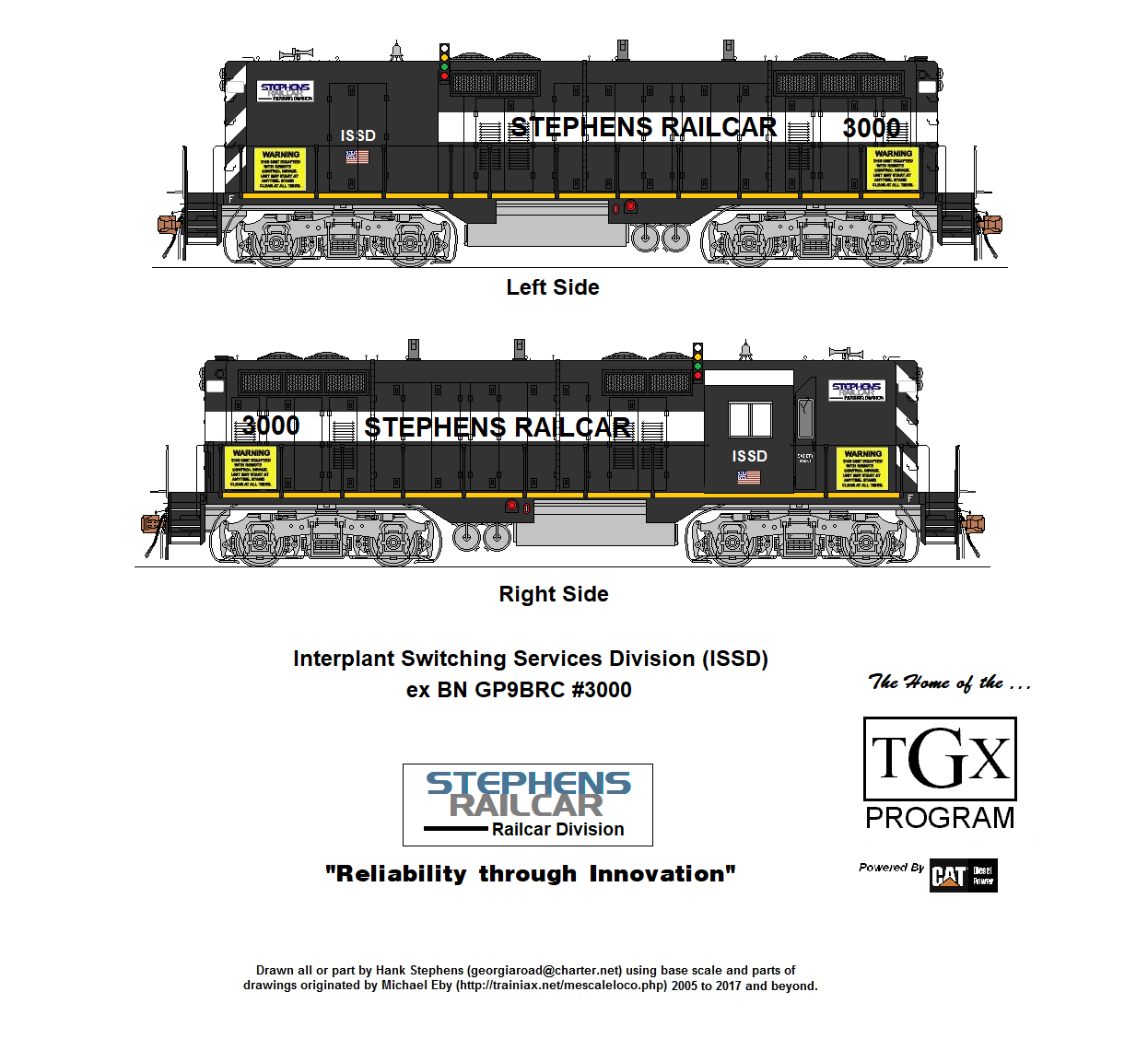

The JTLS facility would require constant switching to move projects around the complex and interchange with Georgia Road at its nearby Leigh Yard built on the grounds of the former Southern Railway Finley Yard. Additional locomotives were purchased by the Dadeville Loop Industrial Railroad (DLIR) and moved to Ensley to work JTLS. These units, like the original DILR units were painted in the black and white corporate scheme with “Stephens Railcar” set in a white stripe on a black carbody. The units assigned to Birmingham carried the Intra-Plant Switching Service Division (ISSD) reporting marks as the only deviation from the DLIR units. Stephens Railcar purchased the site in 2002 and moved all heavy rebuilding to the site, completely reconfiguring and modernizing the historic facility. The “JTLS Shops” as the facility is referred, is the headquarters for Stephens Railcar Services and the home of the TGX Program of OEM remanufactured locomotives. With its opening, the Dadeville Car Shops returned to its original mission as a railcar only shop. JTLS consists of a heavy fabrication backshop for re-capitalization locomotive rebuilds from the frame up. It has a state of the art locomotive paint shop, internal salvage and scrap facility known as Hank’s Truck Electric (HTEX) and full Main Shop floor with a fluid progressive workstation configuration. The ISSD maintains a service shed for its locomotives near the HTEX scrap yard inside the site. The facility is also the home to the Services Division and its Heavy Lift Crane contingent.

In 2016, Stephens Railcar Services acquired the closed Finley Roundhouse at Georgia Road’s Leigh Yard. While Georgia Raod maintained a full repair and service center at its ex Norfolk Southern Fred M Dale Classification yard across town in Irondale, AL It opened limited servicing and running repair at its new Leigh Yard which was built on the old Southern Railway Finley yard site. Findley was the western end of the system during the steam era, and Southern maintained a full Roundhouse, backshop and large yard in what was considered north Bessemer. As Southern acquired neighboring competitors such as the Central of Georgia (CofGA) and Alabama Great Southern (AGS), it eventually combined yards in the form of the new Norris Classification Yard in the eastern suburb of Irondale, AL. Findley became local service only, and the roundhouse was largely abandoned with the backshop buildings removed or repurposed. As the steel mills and foundries closed in the 1980s, Finley was reduced to a few yard tracks in a large open field where the Southern Findley Yard and Terminal used to be. When Georgia Road needed a yard to service unit coal trains and growing intermodal operations at its Ensley Industrial Park location, Leigh Yard was built on top of the old Finley surrounds. The roundhouse was reopened but reduced in size to service run through Scherer Coal train power and QuickSilver Intermodal trains. These trains bypassed the Fred Dale Classification Yard to reduce delays. Some local business provided for a local switching base for Georgia Road operations west of downtown also.

Stephens Railcar opted to build a modern running repair shop and service facility behind the Finley Roundhouse, which once again idled the centuries old building in 2016. Stephens Railcar decided to acquire the structure, now reduced to six stalls and an add on locomotive shop building for use in its TGX Program. The Finley Roundhouse and adjoining trackage became the home of TGX Program research and development as well as an EPA certified emissions testing and research facility. TGX Program designers referred to the fully restored facility as the “Possum Works”, a tongue-and-cheek version of the secretive Lockheed-Martin “Skunk Works” where cutting aerospace projects were planned and produced. Projects at the Possum Works included design and application of later iterations of the TGX Program locomotive rebuilds and recent ENCORE green locomotive initiatives, ARIES automated track geometry system and more. All TGX Program and ENCORE Initiative remanufactured locomotives are emissions tested at the site. In addition, the site regularly re-certifies locomotives for various Class One railroads. Testbed locomotives, TGX demonstrators and the dynamic testing train are also based at the facility.

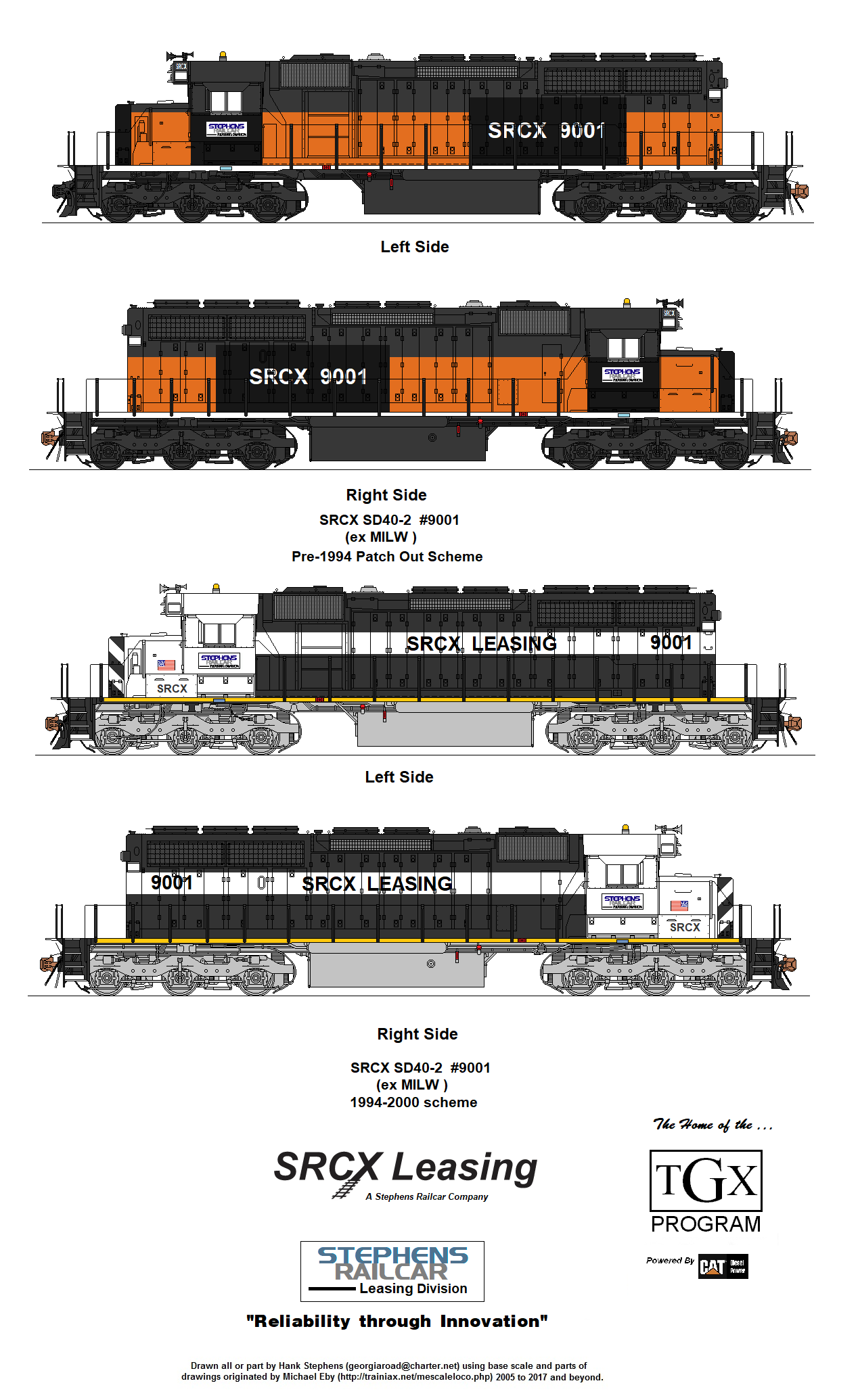

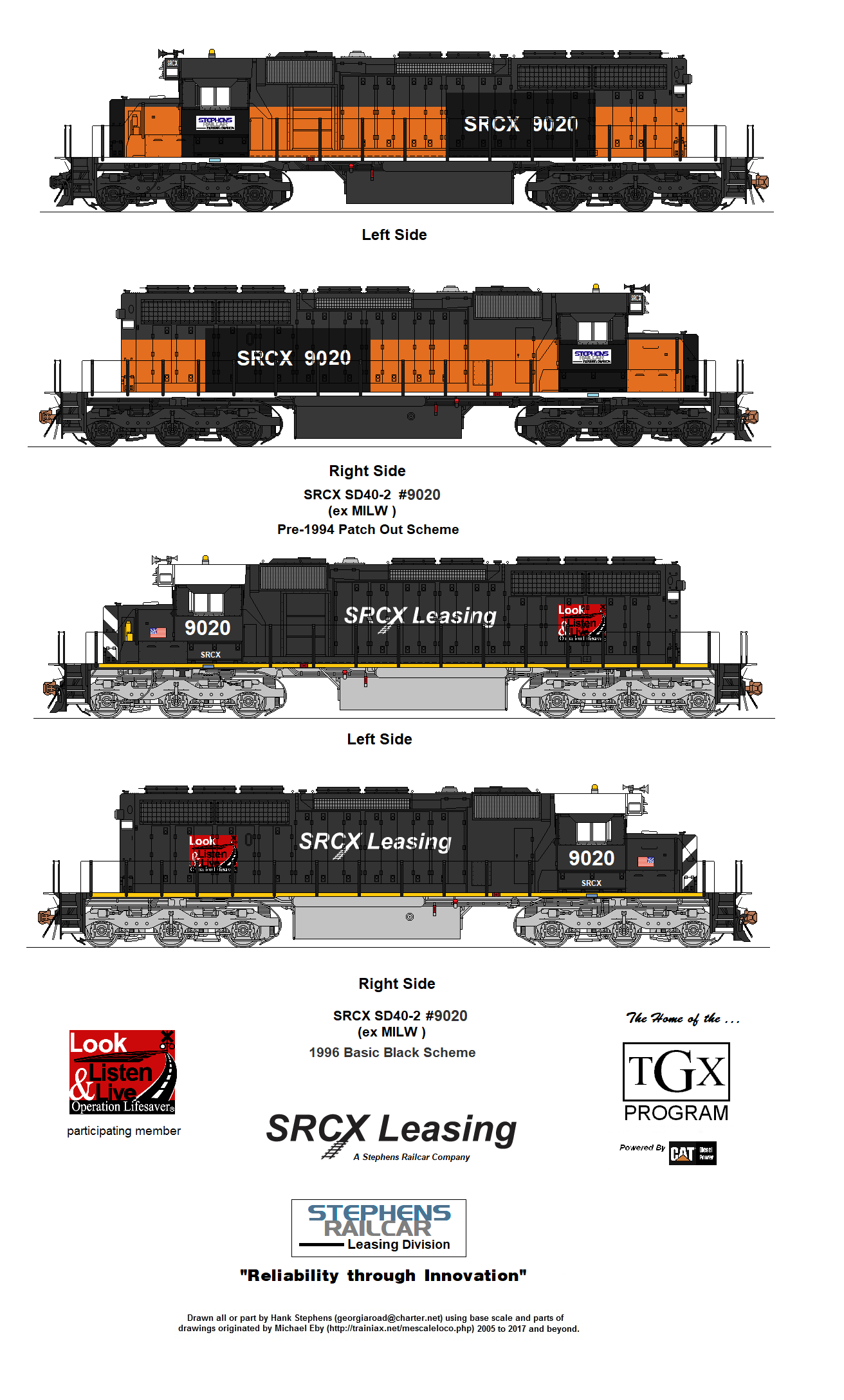

SRCX Leasing

The leasing arm of SRCS came about in the mid-1990s as an attempt by Stephens railcar to counter losses associated with the bankruptcy failure of the Central Alabama & Southern Railroad (CA&S). CA&S was the predecessor to the current Georgia Road which fell into bankruptcy in 1992 after a stellar rise to fame followed by and equally fast fall from grace in less than seven years. SRCS through its Mongomery Car Shops was the primary back shop and repair facility for the CA&S and found its fortunes tied to the regional turned welter weight Class One. Stephens Railcar acquired, rebuilt and maintained a large percentage of the CA&S roster of locomotives and rolling stock. Much of these operations were speculative with highly profitable results as CA&S grew in size and revenue. Unfortunately, the highly leveraged debt fueling the CA&S rise quickly ransacked its cash flow when a series of investments failed and were illegally covered up by the CA&S management team. Clandestine arrangements in the dark eventually come to light, and the weight of falsified financials collapsed the railroad on a weekend in September 1992. Bankruptcy ensued the following week leaving Stephens Railcar holding notes on dozens of locomotives and hundreds of railcars with no hope of recovering payments. After months of wrangling with federal bankruptcy court, SRCS was endowed many of these locomotives and cars as payment for debt owed by CA&S to SRCS. To counter the impending loss, SRCS established a leasing arm to get these fleets back to work earning revenue to stave off its own threat of bankruptcy.

Georgia Road would rise from the ashes of the CA&S, and look to Stephens Railcar Services to help acquire, rebuild and maintain its start-up fleet. SRCS devoted a full business unit to it in 1994 and Stephens Railcar Leasing came into being. Known internally at SRCS as The Leasing Division, it used ARR reporting marks SRCX recently vacated by Sid Richardson Carbon following a merger among the carbon producing companies. A few years later, Stephens Railcar Leasing would shorten its name to SRCX Leasing, similar to how Trailer Train Corporation re-imaged themselves as TTX Corp. Like TTX, SRCX was better known for its SRCX reporting marks than its full corporate name of Stephens Railcar Leasing Division. The company used its leasing side to pull out of the dark financial days following the CA&S disaster, and the division became profitable in 1998. SRCX leases locomotives and railcars off of three tiers, ranging from short term “as is” leases, power by the hour, or complete fleet management and/or maintenance contracts. SRCX Leasing maintains its own independent group of locomotives for hire, including builder new GE and EMD power under its FASTLease fleet. SRCX also oversees the TGX program demonstrators, testbeds and “at large” fleet painted in full SRCX colors of black and white similar to the SLIR and ISSD units. Railcar fleets are primarily aimed at specific customers or perceived gaps where growing commodities show a gap between specific suitable railcars and demand for those cars.

Services Division

The Services division is the newest unit of Stephens Railcar and is headquartered in Birmingham, AL at the JTLS shops site. This division consists of Rapid Response Teams located all over the Eastern half of the United States, which can be called upon for emergency derailment and HAZMAT clean-up. These teams utilize pairs of tracked derrick cranes, Wreckmaster side-boom doziers and heavy lift cranes to provide quick containment and clean-up of any railroad related incidents.

In addition to derailment response, Services Division provides technical support on any maintenance of way project including such things as rail and tie renewal, bridge building and new rail construction. The Heavy Lift segment employs heavy duty cranes and specialized handling equipment to move large, heavy and odd sized cargo and works in tandem with the Rapid Response Teams in derailment services.

DADEVILLE LOOP INDUSTRIAL RAILROAD

| Reporting Marks | Unit Number | Unit Model | Notes |

| ISSD | 1000 | GP22 | ex-SOO experimental wreck rebuild of GP9 using carbody of GP35. Unit was not considered successful and retired and sold for scrap. Purchased by Stephens Railcar for parts but eventually restored to service as a shop switcher after a complete rebuild. Assigned to Intra-Plant Switching Services Division as shop switcher at JTLS in Birmingham, AL In service. |

| DILR | 2000 | GMD-1 | exx-NAR, ex-CN purchased for Dadeville Loop Industrial Railroad (DLIR) serving online customers and Dadeville, AL Dadeville Car Shops (DCS) |

| ISSD | 3000 | GP9BRC | |

| DLIR | 4000 | SW1500 | |

| DLIR | 5000 | SW1504 | |

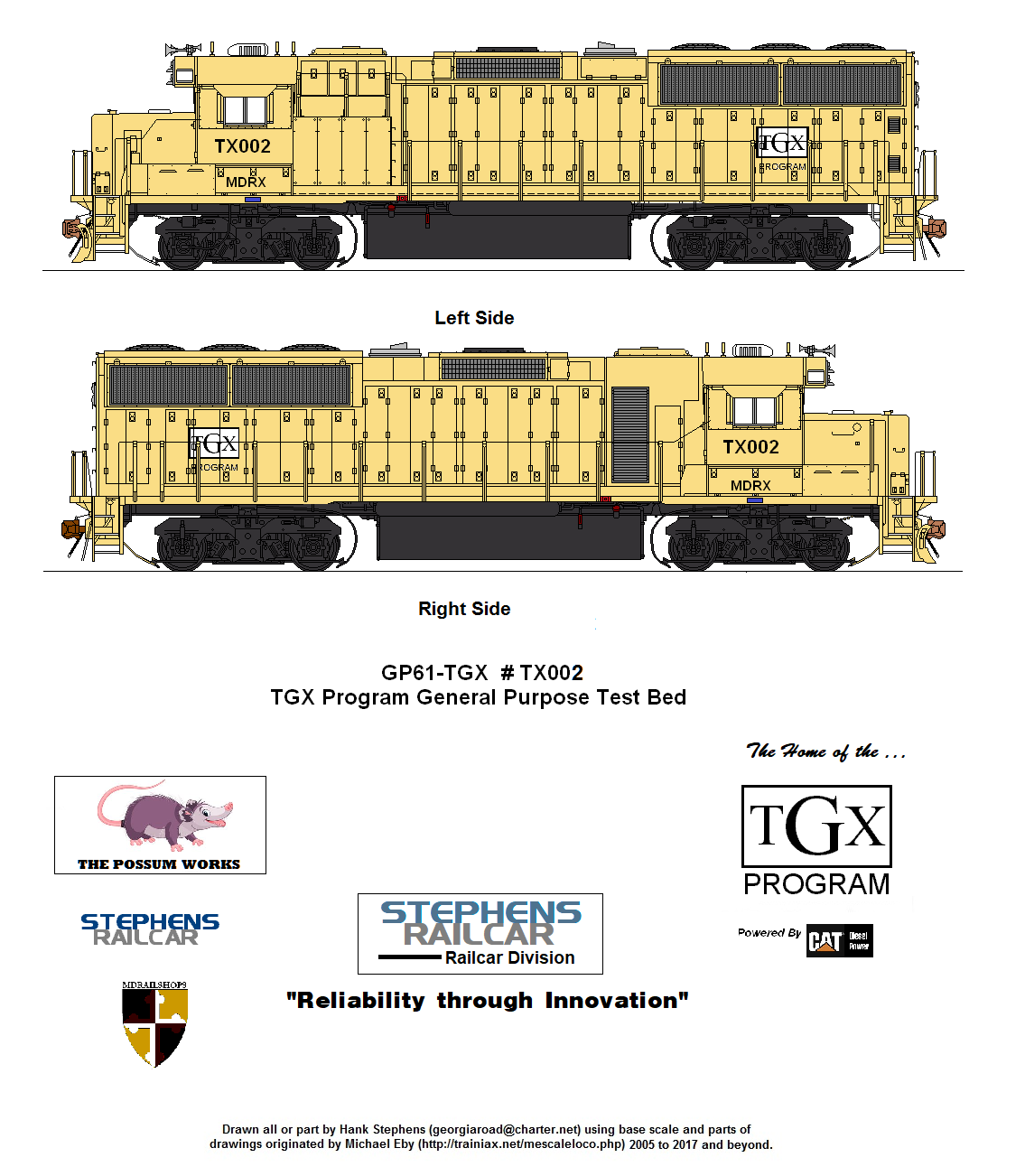

| SRCX | TX001 | GP61-TGX | |

| SRCX | TX002 | GP61-TGX | |

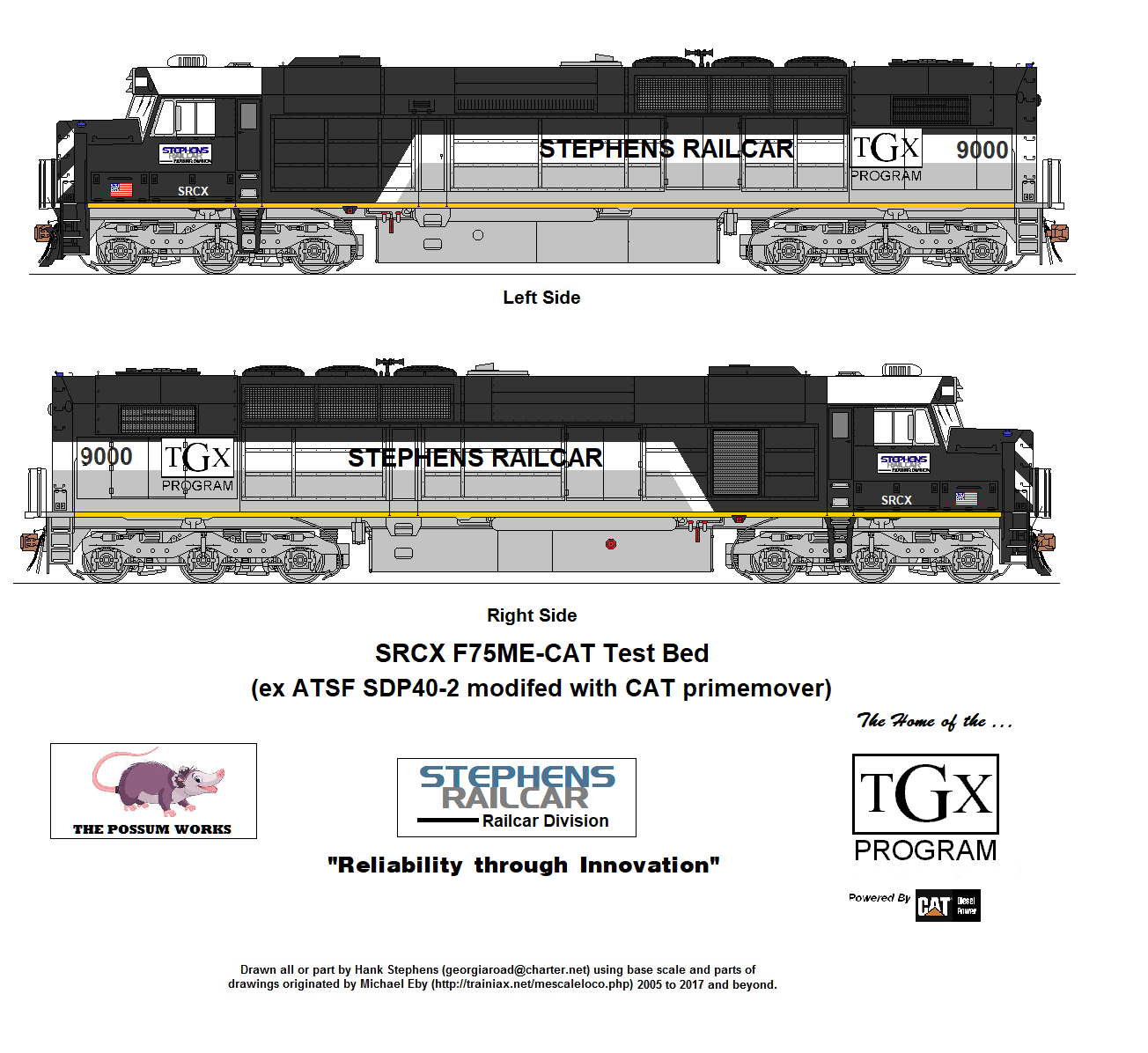

| SRCX | 9000 | FP75ME-TEST BED |