Overview and Concept

The Alabama Midland Railroad (AMRR) teamed up with Georgia Road (GARD) in 2001 in a joint contract to deliver low-sulphur Powder River Coal from the AMAX strip mine in Bill, Wyoming to the Georgia Power owned Plant Miller near Albany, Georgia. Plant Miller was an older peak plant, which burned a mix of Kentucky coal and the Powder River coal to meet the current EPA stack emissions of the time. CSX Transportation (CSXT) held the contract from its startup in the 1960s through predecessor Seaboard Airline RR (SAL)and Louisville & Nashville RR (L&N) until 2000. Predecessors and eventually CSXT delivered coal exclusively from Kentucky mines to the plant. In the 1990s, newer generating plants came online, reducing Plant Miller to a peak plant. This meant that Miller would be running only during peak demand periods in the late summer and winter months. CSXT rationalized much of the old SAL around the same time including spinning off the Albany lines to G&O Railways railroad the Atlantic and Gulf RR (AGLF). By this time, CSX was using trackage rights to deliver the coal to Albany were (AGLF) crews moved the coal trains a few miles south to Plant Miller, unloaded them and returned empties to Albany. CSX provided both locomotives and Georgia Power provided unit coal train cars for the business.

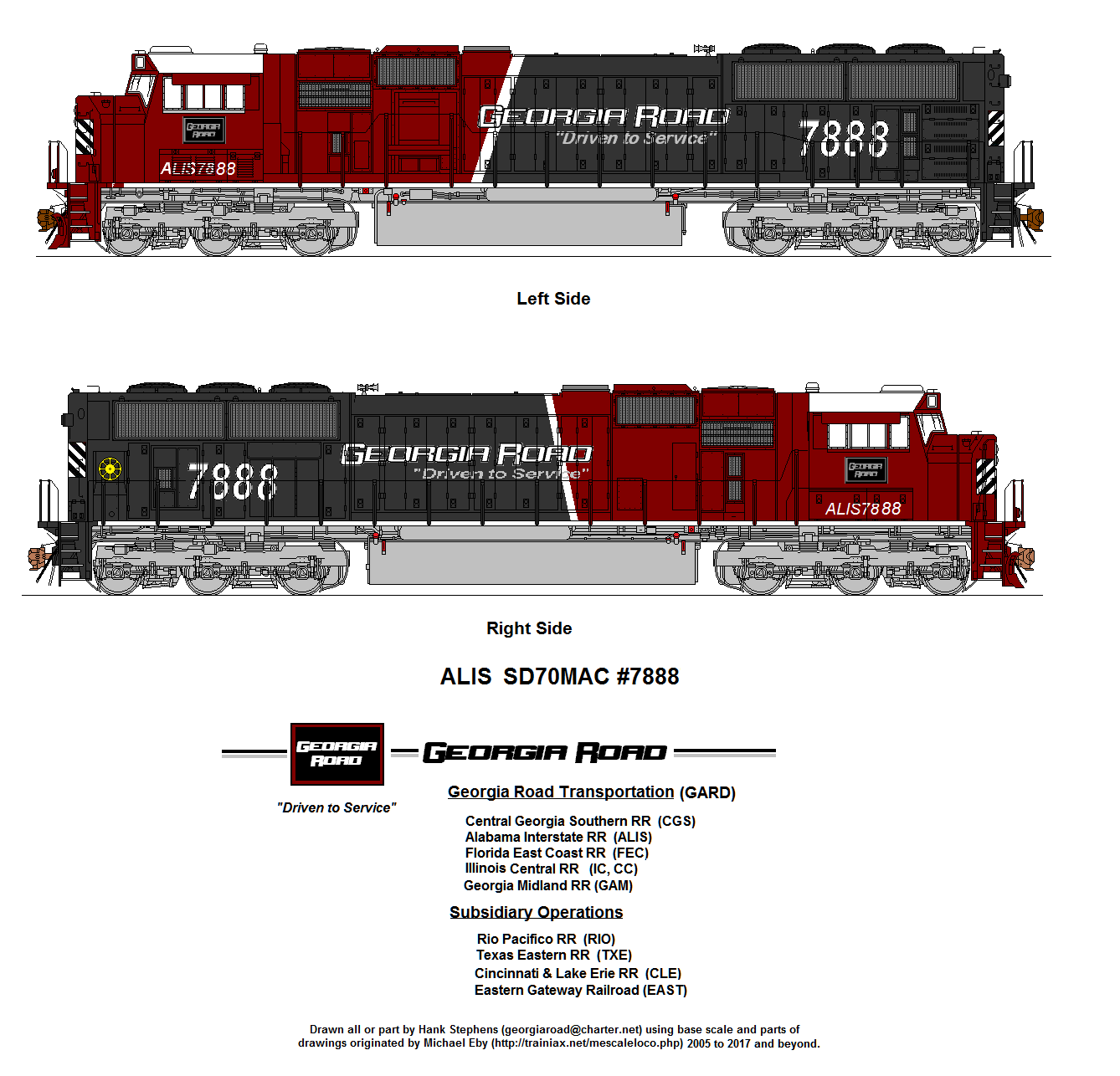

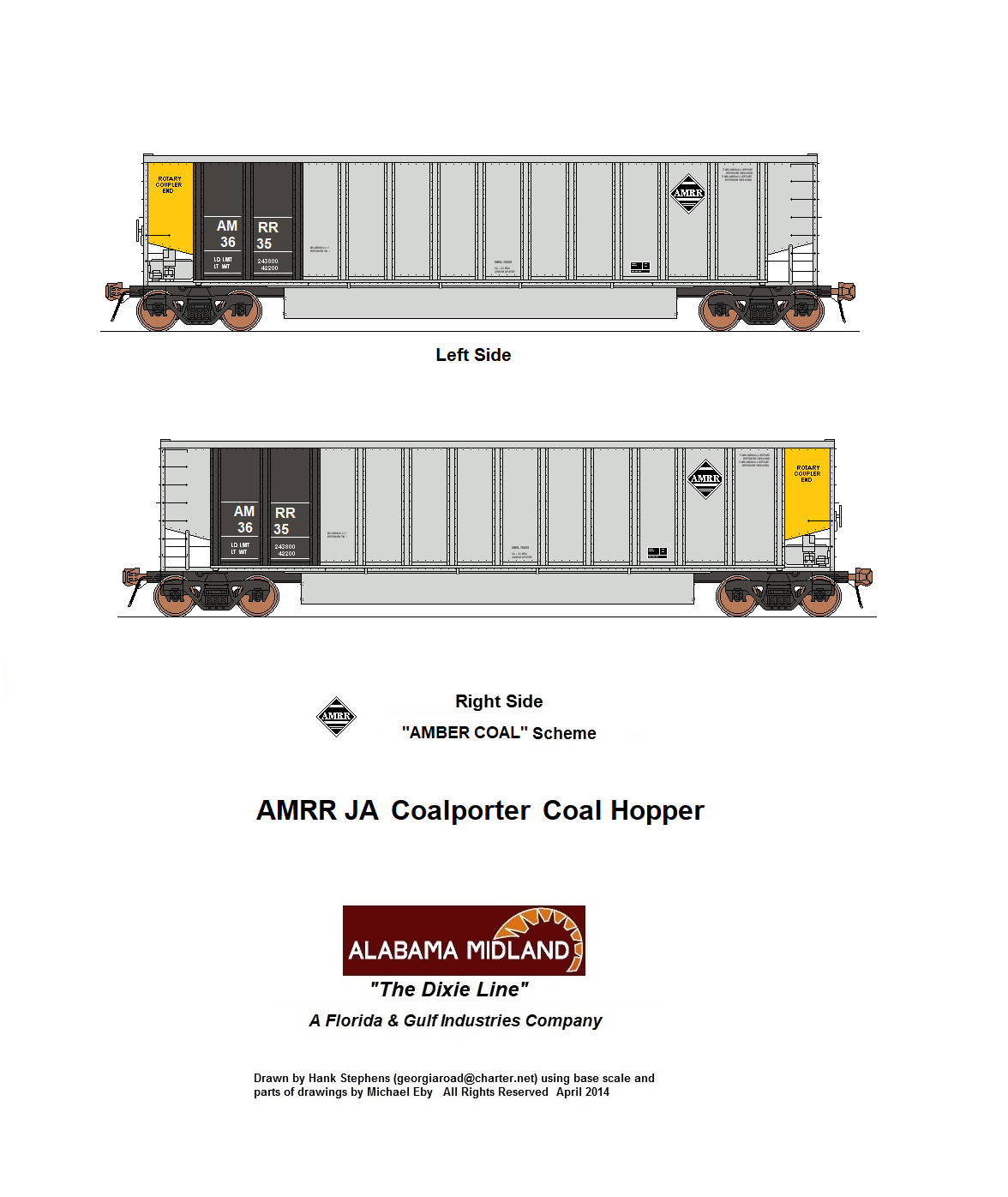

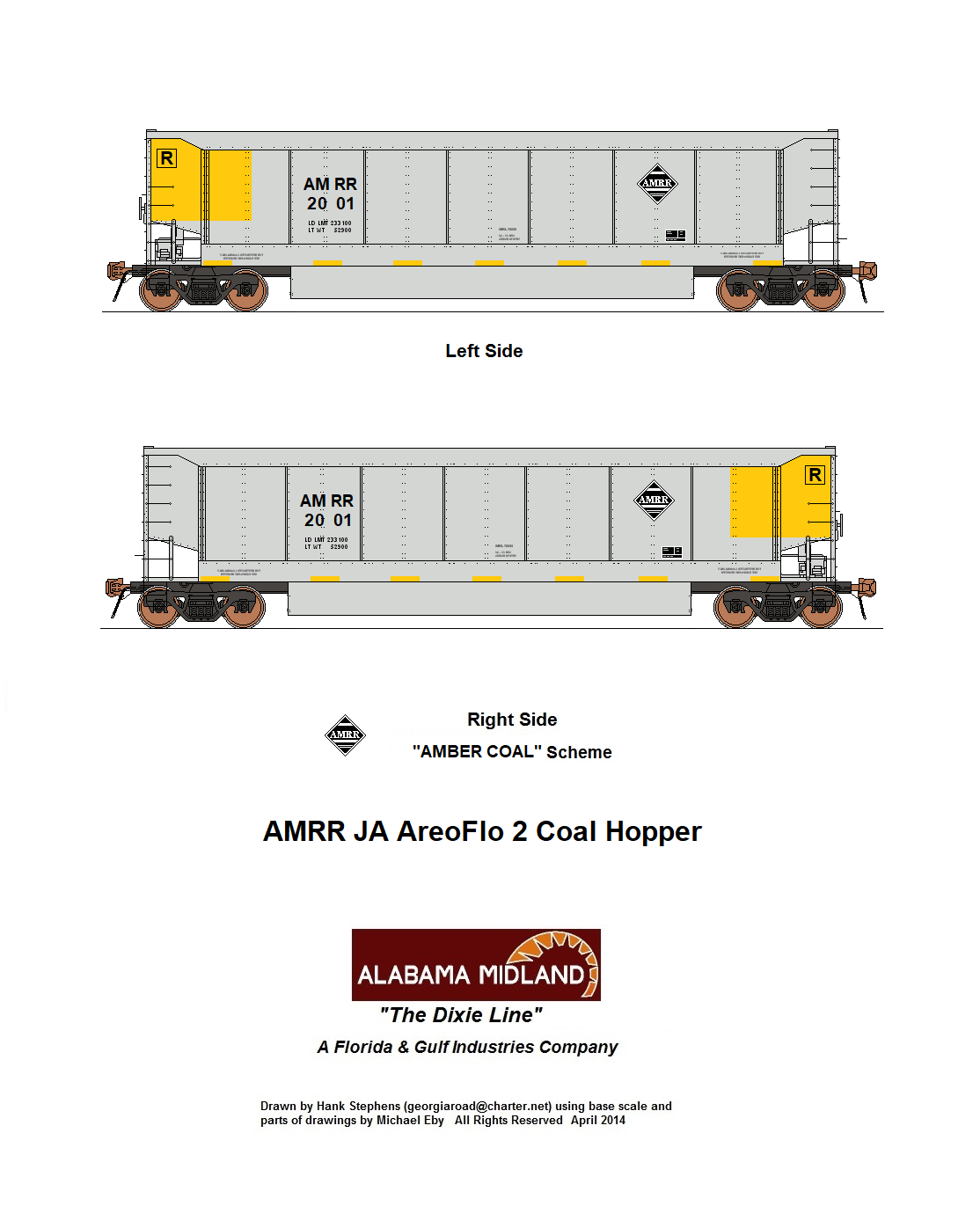

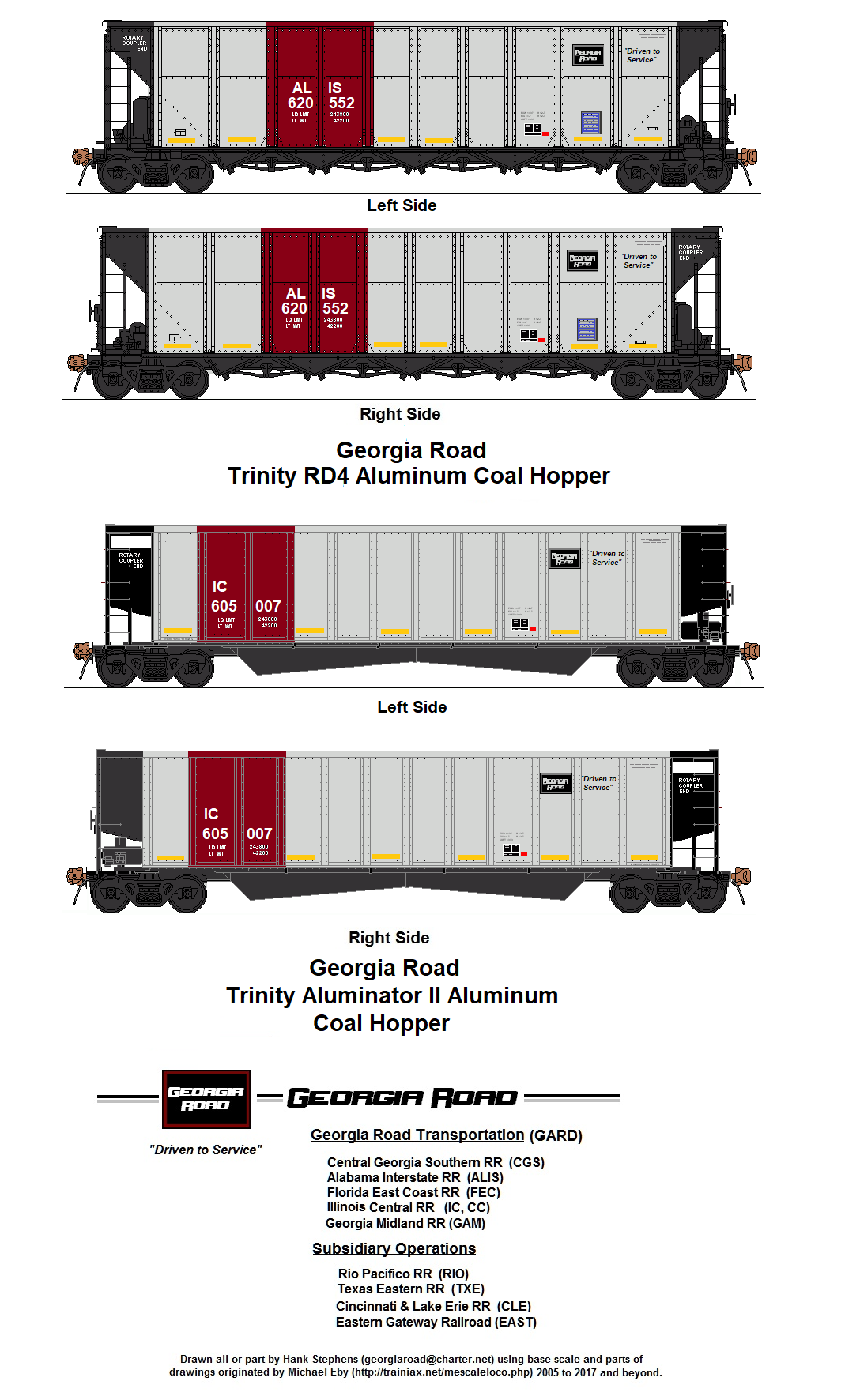

When the Alabama Midland RR (AMRR) took over AGLF operations in 2000, it along with Georgia Road challenged CSXT for the coal train contract and won it. This win was mainly due to the fact that increasingly stringent emissions requirements required Plant Miller to shift to mixing low-sulphur coal with the traditional Kentucky coal it historically burned. The added distance for coal trains to support the contract was a large factor in Georgia Road and AMRR gaining the contract. The two roads had to immediately provide both motive power and additional railcars to support the contract. Georgia Road stepped in to provide its newest SD70MAC and AC4400W locomotives along with Georgia Road owned company cars to start the operation. AMRR set about to procure permanently assigned locomotives and coal cars for the business in the joint agreement. In total, AMRR purchased enough equipment to support two trainsets while Georgia Road provided locomotives and cars for one additional trainset. A two additional trainsets of Georgia Power coal cars were already in the loop, but the added distance across the country to Wyoming required the additional sets. In all AMRR purchased 10 new SD70MAC units from EMD-GMLD constructed to Georgia Road standards and tacked on the end of an Alaska RR (ARR) order of SD70MAC-H units. AMRR purchased 300 aluminum rotary coal cars built by Johnstown America, tacked on the end of an order being delivered for American Energy Producers (AEPX) out of Kansas City, Missouri. Georgia Road provided financing and guarantor status for half the locomotives.

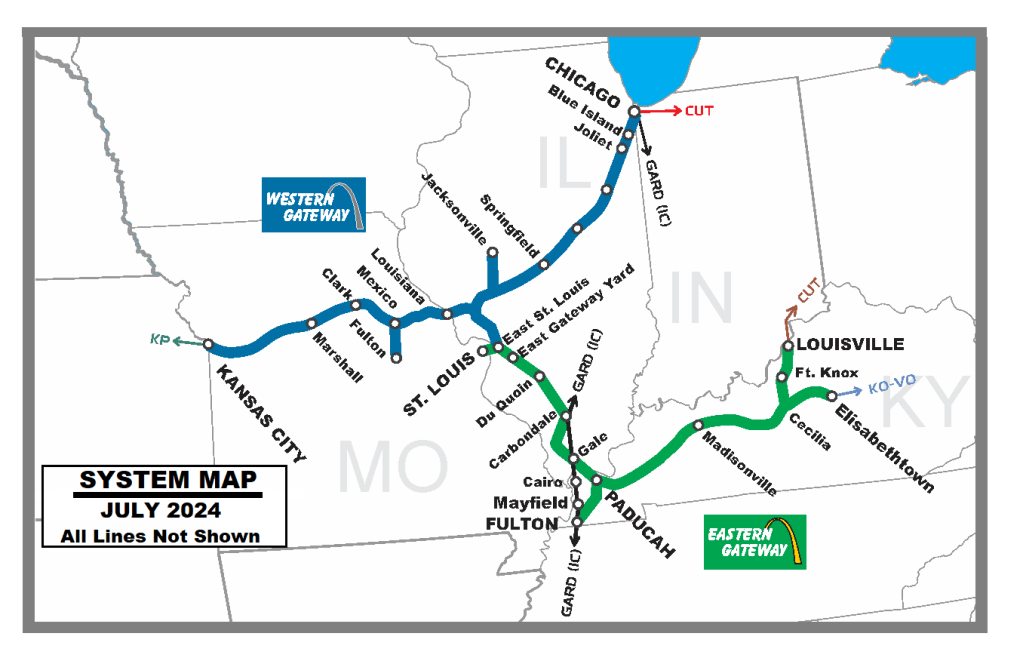

The new routing for the Miller Coal Trains would begin at the AMAX mine in Wyoming and be handled by Union Pacific Railroad (UP) to Kansas City where Georgia Road would then relay the loaded trains from Kansas City to Brimingham, AL. At this point, AMRR crews made the final leg to Albany, GA and unloading at Plant Miller. The empties were cycled back to the mine in a reverse routing. Georgia Road, AMRR and Georgia Power equipment regularly mixed to meet the demand, with UP providing protection power when needed on its part of the routing.

The ten AMRR SD70MAC units were a conundrum on the AMRR roster, as the no-nonsense AMRR was known for its spartan approach to motive power and operations, relying on mostly second hand, non-dynamic brake equipped first- and second-generation hand-me-downs with a few modern rebuilds for its trunk lines. The SD70MACs were equivalent to similar to Georgia Road coal power, required by GARD to ensure all locomotives in the pool would work interchangeably. The SD70MACs were built as an add on behind an Alaska RR order for SD70MAC-H units to speed delivery. The “H” stood for “Heavy” with additional frame weight added to increase tractive effort. This H design worked well for the rugged terrain of the Alaska RR and also for the long-distance aspect of Plant Mitchell Coal Trains. AMRR went so far as to introduce a similar paint scheme as the AMRR units as a time saving option to speed delivery. Eight units were delivered in this scheme, which was rumored to be the new standard scheme of the AMRR, replacing the large “AMRR” billboard scheme used since start up. Georgia Road would step in and specify the last two to be painted in Georgia Road colors. These two GARD units would prove to be the last SD70MACs built for Georgia Road, as additional units on the order were converted to the new SD70ACe specification now required by EPA emission regulations.

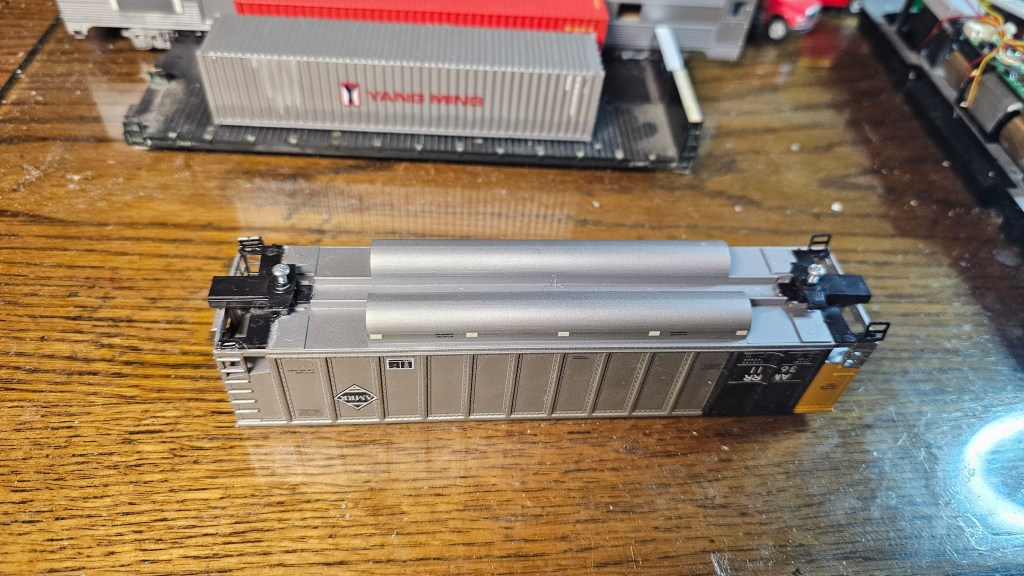

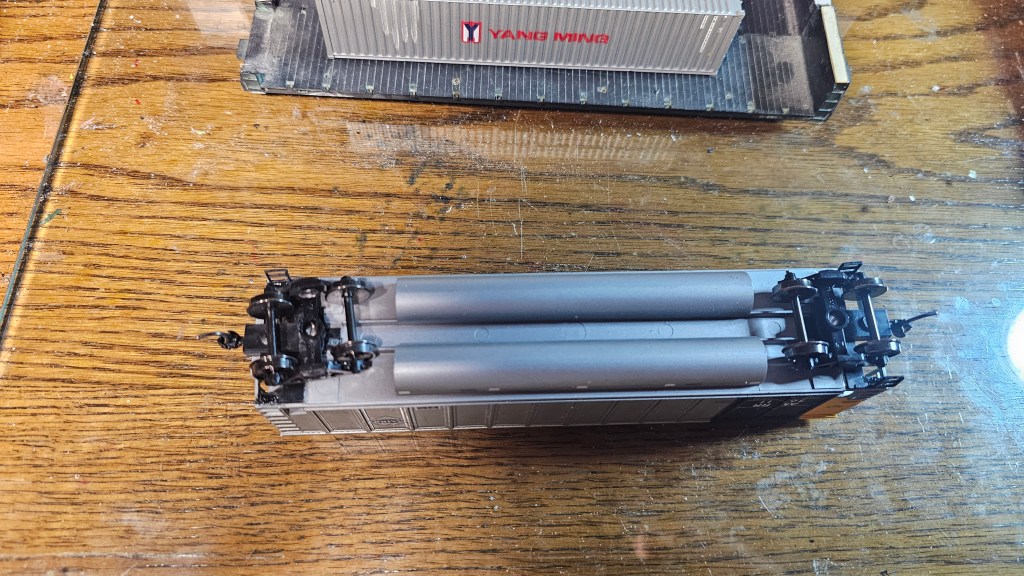

The 350 Johnstown America Coalporter model aluminum hoppers were delivered in late 2000 during most of 2001. They received the black and yellow scheme used by the AEPX cars they followed out of the manufacturing plant to speed delivery., with AMRR logos and reporting marks changed as required. Georgia Road added another 150 Aluminator 2 and later AreoFlo 2 rotary coal cars painted in Georgia Road colors for its part of the contract. Georgia Road also temporarily diverted its company Trinity RD4 trainsets when needed also. A derailment on Union Pacific near Kansas City reduced the AMRR fleet by 21 cars. Twenty-five cars specified for the Georgia Road AreoFlo order were diverted as replacements for the destroyed AMRR cars and were painted in the AEPX style AMRR colors.

Georgia Road and Alabama Midland RR operated the contract without issue into 2010 when Georgia Power opted to decommission the plant instead of upgrading it. Mixing Powder River Coal was no longer a solution for increasing stringent EPA standards, and scrubbing technology was deemed too expensive for such an equally old and small generating plant. Georgia Road quickly re-allocated its power and trains to support growing Georgia Power Plant Scherer operations, leaving AMRR to solely support Mitchell Coal trains until the plant formally closed in 2012. After the plant closure, AMRR trainsets were short-term leased to the Georgia Road during peak demand at Scherer. When demand normalized, the trainsets could be found stored at the AGLF Albany, Georgia yard. The eight AMRR SD70MAC units jointed their Georgia Road siblings in coal or bulk unit train service in reoccuring short term lease to Georgia Road.

In 2018, Florida Gulf Industries (FGI) purchased controlling interest in the independent Alabama Midland Railroad and its system of short lines. FGI had plans of combining the AMRR with its highly successful Floridia & Gulf Coast Railroad (FGC). FGC worked closely with the AMRR, funneling traffic out of Florida and through the AMRR system to its primary Class One interchange at Birmingham, AL. The FGC-AMRR merger solidified operations and increased business on both the FGC and the AMRR lines. AMRR benefited in particular, as the closing of several key paper mills on its system had radically reduced its revenue base. The stored Alabama Midland coal trains got a reprieve from potential divesture sale after the FGI takeover. The FGC gained a coal contract with Tampa Electric Generating Company (TEGCO) serving its Big Bend coal fired generator plant near Tampa, FL. This generator was upgraded in the early 2000s with the latest emissions scrubber technology. It decided to burn coal from mines in Alabama and West Virginia instead of barging coal down the Mississippi from the Midwest. The new trains originated at the Blue Creek Coal mine owned by Attila Resources Kodiak Mining at its Shannon strip mine near Brookwood, AL. Attila Resources also operated several mines in West Virginia off the Virginia & Ohio (V&O) where additional coal was sourced for TEGCO. Big Bend also burned coal from Peabody Energy in Indiana during peak demand. While the Alabama trains turned inside of days, the Indiana and West Virginia trains gathered at Paducah, KY on the Gateway Eastern Railroad (EAST). From there EAST moved them south to be interchanged with Georgia Road at Fulton, KY. Using its ICG lines from Fulton, the Georgia Road moved them to Birmingham, AL where AMRR-FGC power was added for the final leg to Tampa, FL. The interesting aspect of these “resurrected” AMRR trains is the re appearance of AMRR SD70MAC-H units, but with an odd twist. Georgia Road continued to keep the AMRR units on lease and actually assigned them to its part of the TEGCO movements from Fulton, KY. The Georgia Road part of the locomotive power pool ended in Birmingham, AL at the FGC-AMRR interchange, with FGC-AMRR providing existing second-generation power to pull trains from Birmingham to Tampa and back. The irony is the fact that ex-patriot AMRR painted SD70MAC-H units regularly appear on the Georgia Road leg of the Big Bend coal train, only to be cut off in Birmingham, AL in favor of staged AMRR power to move the trains over the AMRR-FGC routing to and from Big Bend.

Updating a Freelance Model to Modern Stardards

Truth be known, my original plans for an investment of Utah Belt unit coal cars offered by E&C Shops/LBF in the early 2000 looked nothing like they are today, some twenty-five years later. I purchased a group of twelve Eric Brooman inspired Utah Belt Railroad (UB) limited release cars from E&C Shops/LBF and waited nearly a year for delivery. I wanted around 18 -24 cars for a scaled down homogenous UB coal train, but budget concerns limited me to twelve as they were pre-order only and my funds were limited. I happened to be slowly building my own AMRR unit coal train at the time, using open stock E&C Shops AEPX cars which had similar colors of my freelanced AMRR. The black and yellow of the AEPX also matched up with the UB cars and I figured a mix in a joint UB-AMRR coal train running from the UB mines to a coal generator in the East on my proto-freelanced Alabama Midland RR was a workable concept.

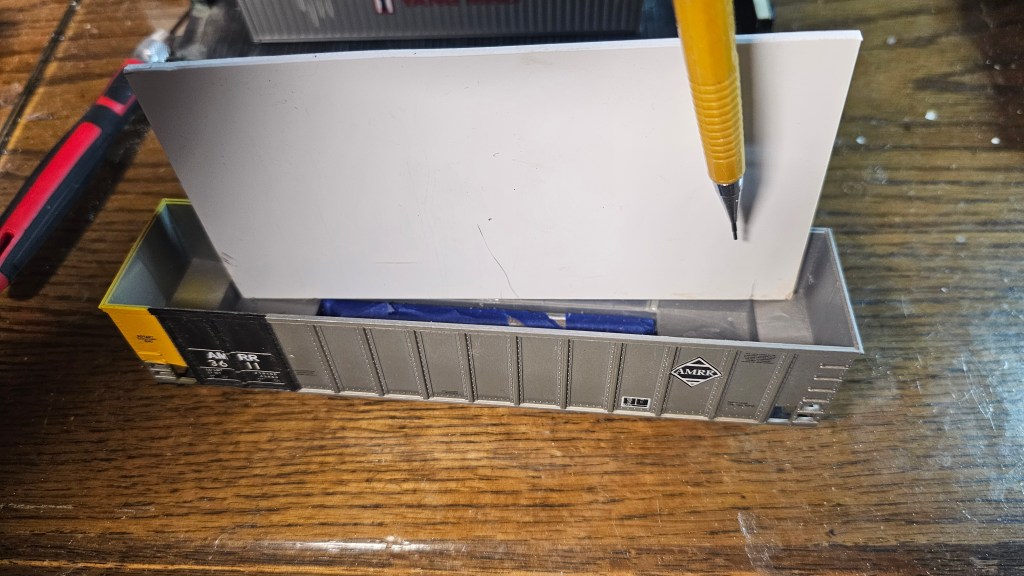

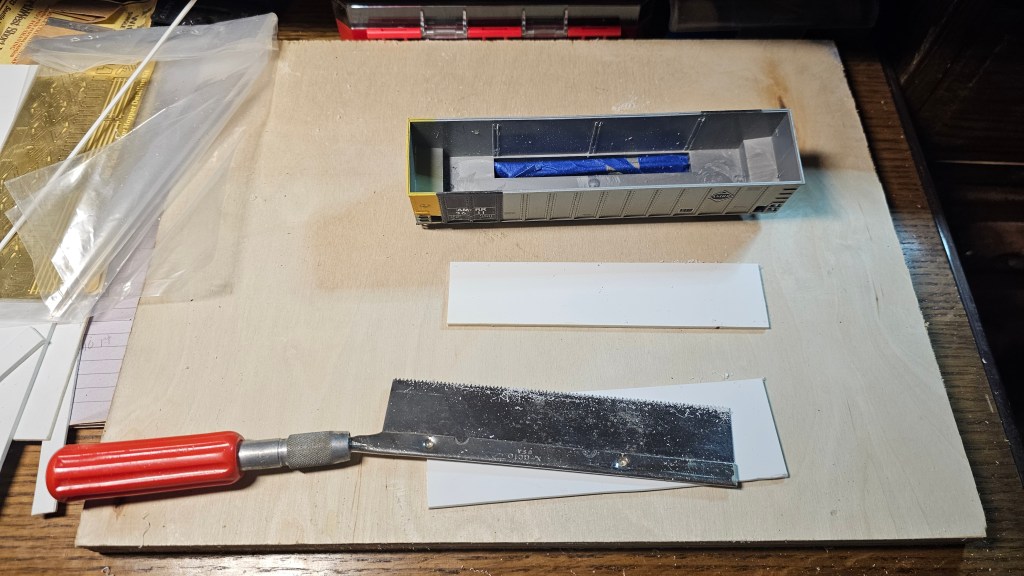

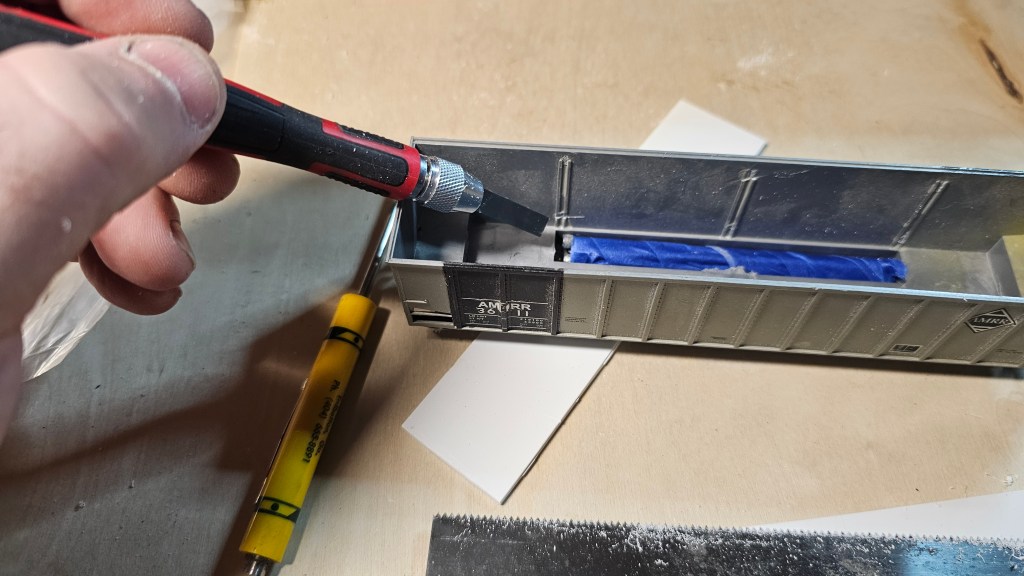

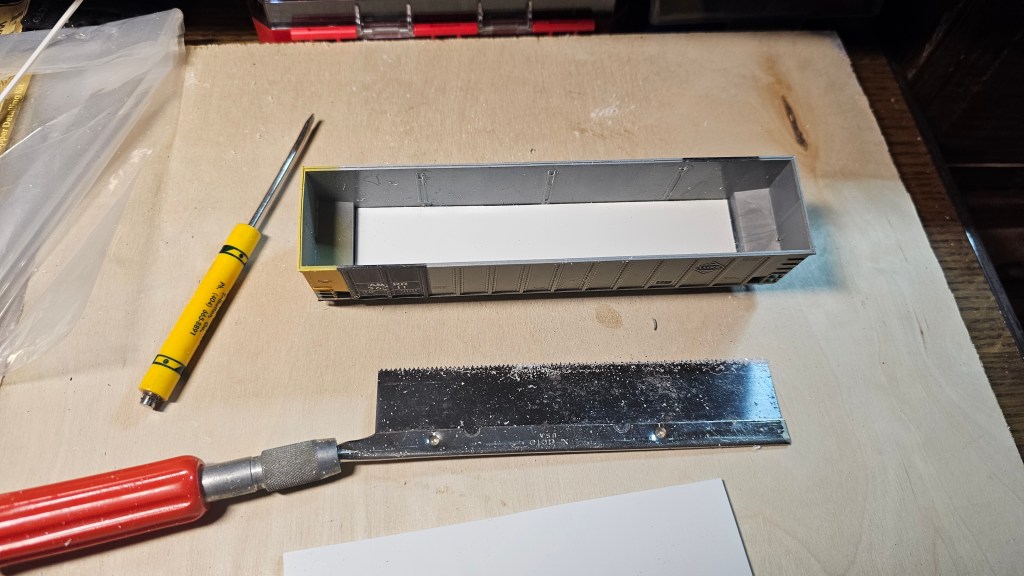

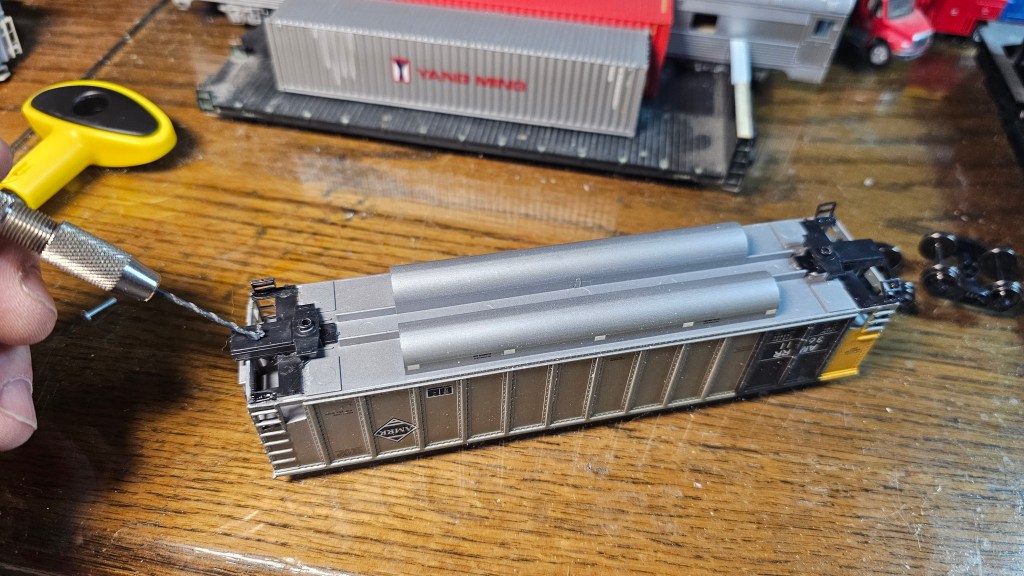

The LBF/E&C Shops cars were cutting edge for early 2000s tooling but suffered from ill cast truck frames and equally suspect wheelsets. The cars required assembly, and I followed the instructions to the letter with the exception of replacing the trucks with Athearn 36″ versions trucks and Kaydee couplers. I changed the “AEPX” reporting marks with “AMRR” from Microscale lettering sets and added custom drawn AMRR logos inspired by the TP&W printed on an ALPS3000 proof printer. With no layout and no access to one, these were assembled and packed down. I felt I did a pretty good job for the time, but as they say, “times be a changing.” Standards moved from Y2F to Kaydee equivalent couplers, and wheelsets evolved into true contour metal wheelsets. Some twenty years later, I revisited the UB and AMRR cars, still packed down safely in totes. I also acquired a few later LBF branded assembled UB cars via Ebay. While going through my recent additions and my packed down collection, I realized these cars needed upgrading to work with current offerings by model manufacturing, where semi-scaled couplers and metal wheelsets were now standard. I was not satisfied with the weight of the cars I built and later Ebay finds, and the E&C wheelsets of the time were far outclassed by the likes of Intermountain, Athearn or Kaydee, all of which offered upgrade trucks and wheel sets. I found with a little work, I could “rebuild” the cars with proper weight and turn cars that rarely ran well into top notch models.

What follows is a step-by-step process that I use to upgrade and increase reliability of what are now somewhat dated and questionable cars. Intermountain released some of the old LBF models and paint schemes along with some data only RTR cars in their Value Line recently. These Intermountain cars haver metal trucks, Kadee type couplers and near standard weight. I used these upgraded cars as my new standard, and I went to work on my substantial fleet of kits acquired so many years ago. While replacement would be so much easier, some of my AMRR and UB cars impossible to find or I have too much tied up to cast them aside. I am a believer in the Jim McClelland (V&O fame) “layout quality model”. Even substandard cars con be made into workable models with a little work and while working on a layout, they do not detract from the overall look and feel. As a result, these older kits and models have intrinsic value to me, and worth my efforts as I hope you see.

With the backstory and model complete, the article is also finished. I find that model railroading, particularly prototype freelance modeling, evolves over time. Research and prototype observation leads to more ideas to implement in modeling, and the effort to create a layout melds various ideas and themes in new and previously unknown ways. A good backstory goes a long way in believability, even for basic models. Prototype modelers inherit the backstory and assumptions based on the model. Extrapolating the real for the assumed to the completely fabricated is just as much a part of freelanced modeling as the model itself. The extra work for a prototype freelance modeler is knowing the prototype, bending it in believable ways, then creating models that fit in both prototype and freelance worlds.

Let’s get to modeling!

END OF LINE