In my neck of the woods in West Georgia, an industry or spur taking tank cars is a novel find. This is not to say there are not tank car industries, but most are connected to large manufacturing facilities that take up a great deal of modeling real estate. In the case of the Universal Enviromental Services (UES), I found a unique industry to model that is perfect for a small or medium sized layout.

After a Google search, I found out UES is a company that makes a living collecting and recycling used oils from manufacturing and automotive sources. Much of it is collected at auto mechanic garages, dealerships and also manufacturing. Trucks are dispatched on routes and collect the oil based on type and grade, then bring it back to the transload yard where it is loaded on tank cars. These are shipped to a processing facility, which in this case is about an hour away in Peachtree City, AL.

For more information, see the official company website https://universalenvironmentalservices.com/

The rising cost of diesel fuel, shortage of CDL drivers and a need to live up to its “green industry” classification prompted the facility to work with CSX to create local transfer yards where oil could be aggregated, fill tank cars and move in larger and more green (i.e. less trucking) railcars to the processing plants. The truck driver is based at the yard, runs a local route and returns. Recycled oil can then be loaded using a portable pump onto the waiting tank cars.

This industry occupies a former stick wood pulpwood yard that has been in place all of my fifty plus years. It was idled in the early 2000s when stick wood fell out of fashion in favor of large logging outfits that moved tree-length by truck. After the wood stopped running, the yard, consisting of an office, a few loaders and the spur were left abandoned. The loaders left, likely for scrap or modification for larger logs, and the spur became an intermittent tie up location for MofW gangs, company material cars and the like. The flat lot around the spur collected track department supplies, a damaged TOFC trailer, and plenty of overgrowth.

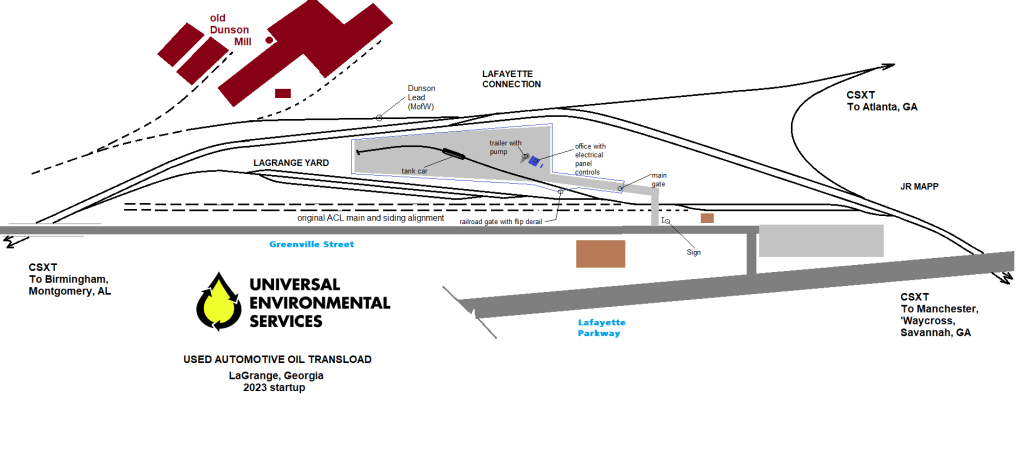

The old wood yard had a long history. The original pulpwood spur was sandwiched between to the former Atlantic Coast Line and West Point Route main lines that paralleled each other through town before going their separate ways. CSX would eventually own both lines, the former ACL now its Lineville Subdivision between Birmingham, AL and Manchester, GA and the West Point route keeping its name as the AWP-WofA Subdivision from Montgomery, AL to Atlanta, GA. In the late 1990s, a road expansion project moved both the main lines onto the AWP-WofA alignment through town. Gone was the old downtown yard, the depot and the switcher based there. Two new connections were made to combine and split the two lines as they meandered through town. Main Street Interlocking erased the downtown yard and depot. The Lafayette Connection was a section of new track to reconnect to the Lineville main above the old Transfer Yard. The new connection “landlocked” the woodyard with rail on all four sides. The woodyard used to pull off the old ACL sidng and main, but now was part of the truncated piece that had been bypassed by the new connection. Over the years, CSX used the old yard and former main and siding to hold ballast trains, swap manifest blocks, collect and hold MofW gang trains, and originate a road local that replaced the LaGrange Switcher. As years went on, the main and siding was removed past the transfer yard, and activity was limited to the occasional MofW use.

Looking into truck entrance with spur entering railroad gate in left background of picture (signal was staged for an unrelated siding project in the area)

In early spring, I visited as I do on occasion lloking for CSX MofW subjects to photograph, and found a totally new look. The old wood yard spur was completely rebuilt, it was being fenced in and contractors were finishing a complete rebuild of the original pulpwood yard office complete with significate power supply upgrades. New gravel coated the whole wood yard lot and signage was place at the entrance of what was the old woodyard.

Former pulpwood office converted with underground electrical to power facility pumps, lights and miscellaneous etc. A portable transfer pump trailer staged near it.

Former pulpwood yard office converted to office for transload yard. Notice underground power to run transfer pumps

View of rebuilt woodyard spur with tank car spotted. This is the actual transfer spur inside the gate.

View at railroad gate of derail– Track to left goes into facility– To the left leads back into the former CSX transfer yard.

In late October, I returned to the facility to find it in full operation. It appeared to be in the early stages of operation. There were tank cars spotted, spill catch basins installed and semi-trucks used to pick up and transload the used oil. Floodlighting was added on newly set telephone poles for late evening operation and security. The spartan nature of the operation was evident still, with minimal equipment needed to operate the facility.

In early January 2024, I successfully caught the CSX AWP-WofA Subdivision local road switcher L817 working the industry for the first time. This is a combination road local/yard switcher assigned to the area. All cars come from the south end of the line at Montgomery, AL, and are left for the L817 at West Point, GA in the old siding. L817 makes the journey to West Point to swap inbound and outbound cars and returns 30 miles north to work LaGrange, GA industrial spurs, the UES oil spur being one of them. After sorting out cars in the three-track transfer yard, empties are swapped for loads. The next day, the loads are gathered with other outbound cars and the journey is made to West Point, GA to swap cars and start the whole process over again. The “oil yard” as crews call it, is worked 2-3 times per week.

This industry makes a perfect modeling subject for a small to medium sized traffic source. The backstory of a very old spur losing its luster, languishing for years and being reborn as a modern “green” industry is very appealing. Any old spur or yard track with some room for trucks to pull in and use portable equipment to transload used oil would be appropriate. A Walthers office kit or something a little more vintage, a kitbashed set of pumps on a trailer, the portable manway stairs and semi-trucks would be all that is needed to start operations. Add a few tanker trucks and tank cars and the facility will be open for business. I did see the addition of spill containment and catch basins at each tank car spotting location for spillage control. EPA spill control is serious business, and the addition of these details indicates the facility is now in full operation.

I plan to keep an eye on this interesting industry and incorporate it somewhere on the Georgia Road layout plan. For now, it is simply a great subject providing food for thought.

H in AL